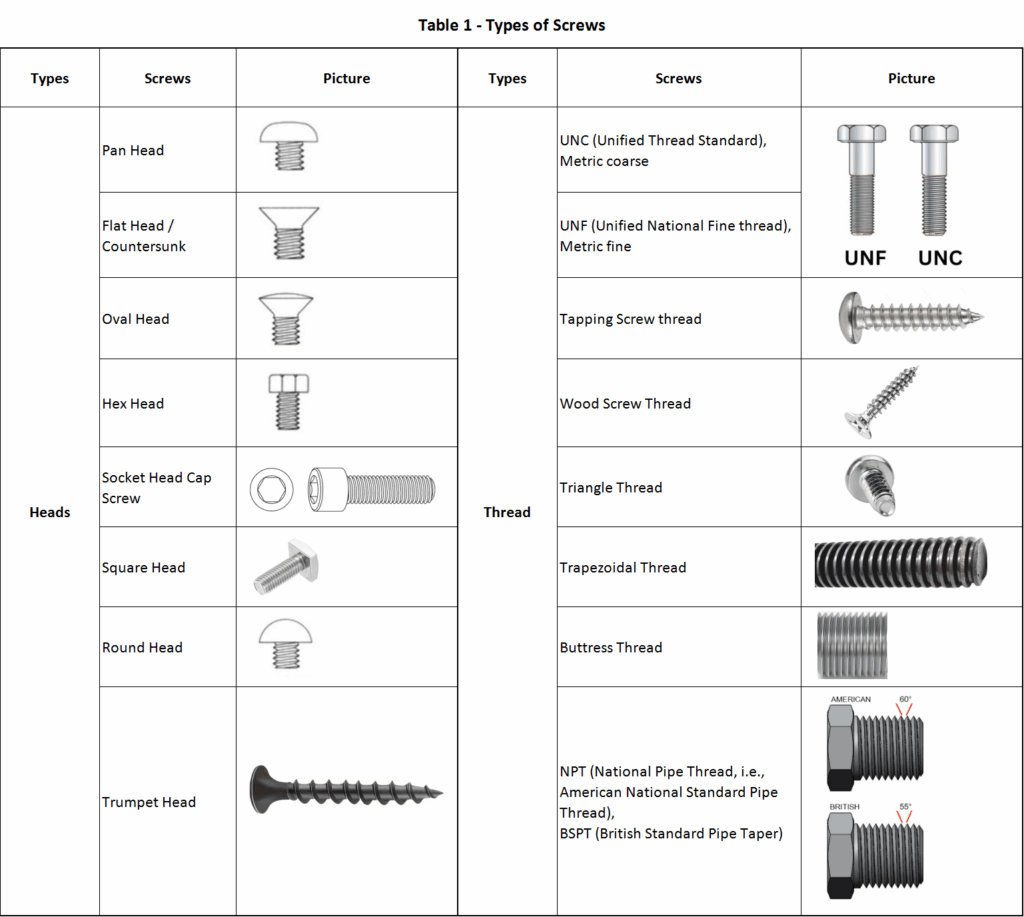

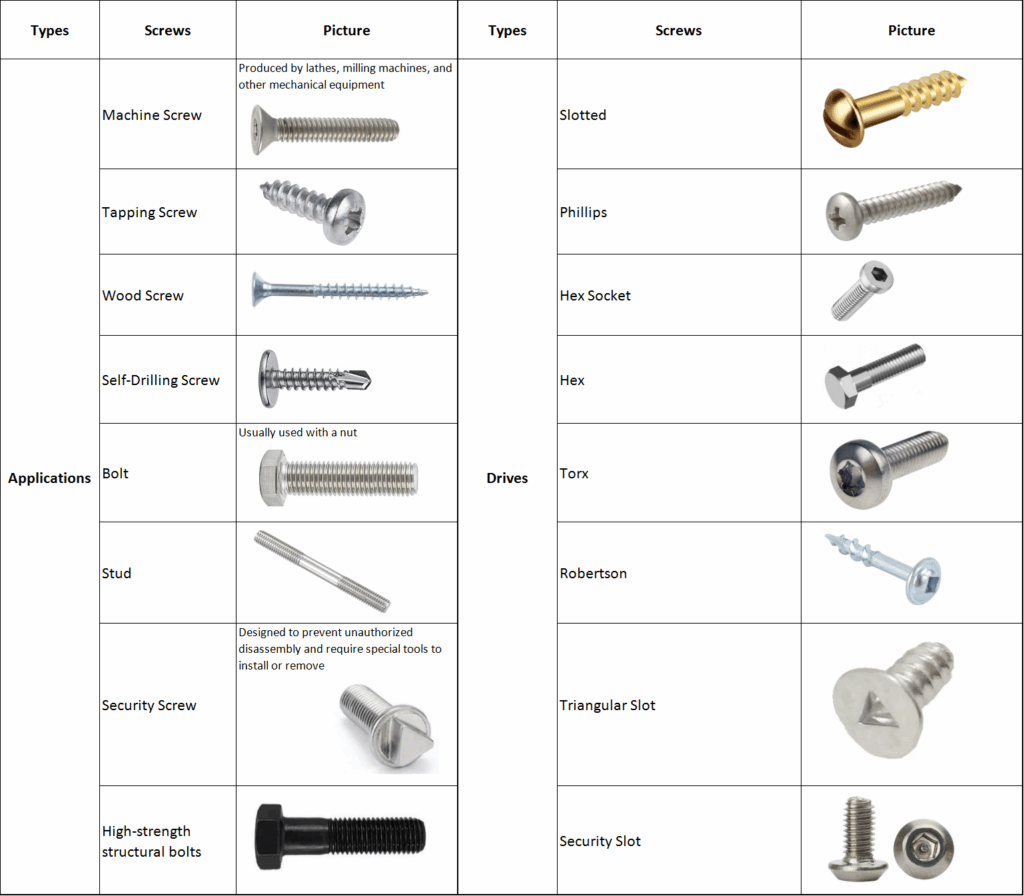

1. Types of Screws

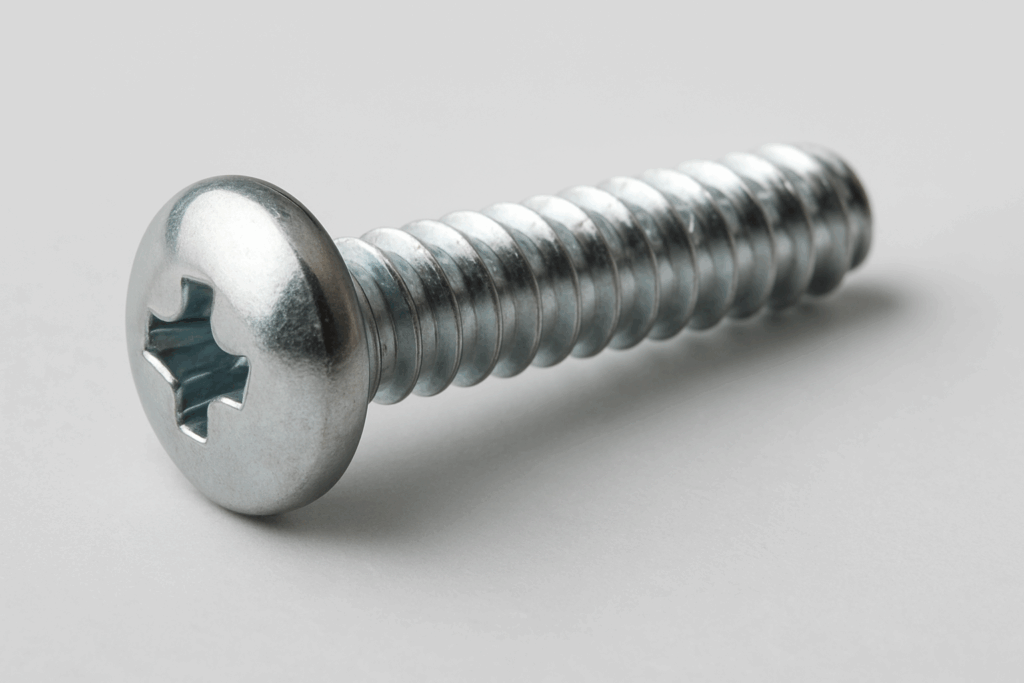

2. Pan Head Screw

2.1 Features

Appearance: Slightly rounded top and a flat bottom.

Load-Bearing: The larger head provides a larger load-bearing area than countersunk or round head screws, making it more suitable for surface attachment.

Fitting: The head does not penetrate the workpiece surface, but presses directly against it.

2.2 Advantages

Easy Installation: The large head eliminates the need for countersinking and can be tightened directly.

Uniform Force Distribution: The large contact area minimizes damage to the workpiece surface.

Versatile: Suitable for a variety of materials, including metal, wood, and plastic.

Decorative Appearance: The rounded top offers a pleasing appearance and can sometimes serve as a decorative feature.

Good Loosening Resistance: Optimized when used with washers or spring washers.

2.3 Disadvantages

Protrusion Effect: After screwing in, the head will protrude from the workpiece surface, making it unsuitable for applications requiring flush or concealed installation.

General Shear Resistance: Incomparable to larger fasteners like hexagonal head bolts.

Unsuitable for High-Strength Structural Parts: More commonly used for medium- and low-strength fastening applications.

2.4 Common Applications

Electronic and Electrical Appliances: Securing plastic housings and metal brackets (such as computer cases and appliance housings).

Furniture Industry: Connecting panels and metal parts for easy installation and removal.

Mechanical Equipment: Fastening small brackets, shields, and thin plate components.

Architectural Hardware: Connecting lightweight structural components, such as door and window hardware and decorative components.

Automotive Industry: Securing interior trim and non-load-bearing components.

2.5 Conclusions

Pan head screws have a sleek appearance and are easy to install. They are suitable for applications requiring a large contact area and a high appearance without a flush fit or extreme strength. For applications requiring a concealed, higher-strength connection, countersunk or hex head screws are preferred.

3. Screw Manufacturing Process

3.1 Turning

Features: A machine tool (such as a CNC lathe or automatic lathe) cuts metal bar stock or rod to produce the screw head and threads.

Applications: Small batches, precision parts, and custom screws (such as those used in medical, aviation, and instrumentation).

Process:

1) Material Preparation: Select metal bar stock (copper, stainless steel, titanium alloy, etc.).

2) Turning: Machine the screw rod diameter and head shape on a lathe.

3) Thread Forming: Direct turning on a lathe or tapping with a tap or die.

4) PostProcessing (Optional): Grooving, Drilling, Hexagon Socket Tapping, etc.

5) Heat /Surface Treatment: Increase hardness or corrosion protection as required.

✅ Advantages: High precision, suitable for complex and special-shaped screws.

❌ Disadvantages: Low efficiency, high cost, not suitable for mass production.

3.2 Hot Forging

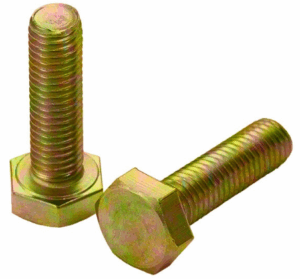

Features: The metal is softened at high temperatures and then stamped into a screw blank (head + shank) using a die. This process is commonly used for large-sized, high-strength bolts.

Applications: Large-diameter bolts (e.g., M20 and above), high-strength screws (for construction and mechanical structures).

Process:

1) Cutting: Cut the steel bar into specified lengths.

2) Heating: Place the bar in a heating furnace (approximately 1000°C).

3) Die Forging: Use a die to stamp out the screw head shape.

4) Finishing: Remove burrs and trim the blank.

5) Turning/Thread Rolling: Produce threads (mostly thread rolling).

6) Heat Treatment: Quenching and tempering to increase strength.

7) Surface Treatment: Galvanizing, blackening, nickel plating, etc.

✅ Advantages: Dense structure, good mechanical properties, high strength.

❌ Disadvantages: High cost, less efficient than cold forging.

3.3 Cold Heading

Features: Metal wire is punched into screw blanks at room temperature using a high-speed punch press, and then rolled into threads. This is currently the process with the highest production output and highest efficiency.

Applications: Standard parts and large-volume screws (such as electronic screws, self-tapping screws, wood screws, and automotive screws).

Process:

Take Selt-Drilling Screw as an example:

1) Wire Selection: The required wire diameter must be larger than the corresponding product diameter

2) Wire Processing

I. Rough Drawing: Removes surface oxide scale formed during production and storage.

II. Annealing: Heats the wire to different temperature ranges, holds the temperature for a specified period, and then cools it naturally in air to reduce hardness and eliminate stress, facilitating subsequent processing.

III. Pickling and Phosphating:Adds a phosphate coating to the wire, making it easier to form and reducing mold wear.

IV. Finish Drawing: Draws the wire to the appropriate diameter based on product requirements.

V. Wires must pass inspection before proceeding to the next forming process.

3) Forming

I. Cold Heading:The cold heading machine cuts the wire into the required length and simultaneously punches the nut and marking.

II. Tailing (Critical): Creates a dovetail shape that can penetrate steel plates. Parameters such as concentricity and blade width must be strictly controlled.

III. Thread Rolling: Rolls the threads onto the screw surface.

4) Heat Treatment

I. Cleaning: Use hot water to remove grease from the screw surface (two washes).

II. High-Temperature Carburizing (Core Step):Allow carbon atoms to penetrate the screw surface, increasing its hardness. Temperature and time control, as well as the concentration and ratio of the gas carburizing, play a decisive role in this step.

III. Quenching: Quenching is performed at high temperature in quenching oil. The combination of carburizing and quenching forms a layer of crystals on the screw surface, achieving the required surface hardness.

IV. Cleaning: The purpose of the second cleaning step is to remove the quenching oil from the screw surface (two washes).

V. Low-temperature tempering:It reduces the core hardness of the screw. Excessive core hardness can easily cause self-drilling screws to break. Low-temperature tempering imparts a certain degree of toughness to the screws.

5) Testing

After heat treatment, test screw surface hardness, core hardness, torque, and tapping speed to ensure all parameters meet standards.

6) Surface Finish

I. Pickling: Thoroughly cleans the screw surface of oil stains.

II. Electroplating: Prevent rust and extends the life of the screw.

7) Washer Attachment

Install a pre-attached sealing washer to prevent water from seeping into the screws during use.

8) Packaging

Pack the screw as per requirements.

✅ Advantages: Extremely high efficiency, good material utilization, low cost, and high thread strength (fibers remain continuous and uncut).

❌ Disadvantages: Not suitable for large-diameter or special-shaped screws.

4. Thread Forming Methods

| No. | Method | Pictures | Features | Advantages | Disadvantages |

|---|---|---|---|---|---|

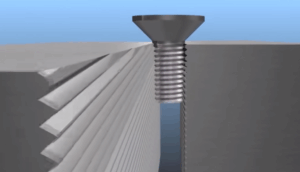

| 1 | Thread Turning |  | Using a lathe (conventional lathe, CNC lathe) to cut and machine with a threading tool | ● Suitable for large-diameter, non-standard, single-piece, or small-batch threads; ● Highly versatile ● High precision | ● Low efficiency ● Rapid tool wear ● Unsuitable for mass production |

| 2 | Thread Milling |  | Processed using a thread mill or specialized tool on a milling machine or machining center | ● Can process blind and through holes ● Good chip removal ● Suitable for hard materials ● High precision | ● Low processing efficiency ● High tool cost ● Requires high machine tool rigidity |

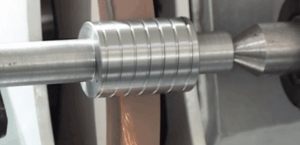

| 3 | Rolled Thread |  | Cold extrusion using a rolling die (rolling wheel) | ● Chipless, continuous material fibers, high strength and fatigue life ● Smooth surface ● High efficiency, suitable for mass production | ● Suitable only for metals with good plasticity ● Thread outer diameter must be larger than the finished product ● High equipment investment |

| 4 | Washboard Extruded Thread |  | Tapping relies on extrusion (chipless tapping) | ● Chipless, high thread strength ● High material utilization ● Suitable for malleable materials (aluminum, copper, stainless steel, etc.) | ● High torque, limited tool life ● Unsuitable for brittle materials ● Strict hole diameter requirements |

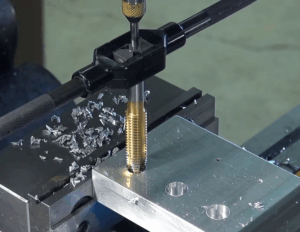

| 5 | Tapping |  | Using a tap to cut threads into an internal hole | ● Simple process ● Commonly used, low-cost ● Suitable for batch processing of small-diameter internal threads | ● Difficult chip removal, easy tap breakage ● Inconvenient for processing deep holes and hard materials |

| 6 | Threading |  | Cutting threads on the outer surface of round rods using a die or threading machine | ● Simple and convenient ● Suitable for small-batch external threading | ● Low precision ● Rapid tool wear ● Not suitable for large diameters or large quantities |

| 7 | Thread Grinding |  | Grinding with threaded or profiled grinding wheels | ● Highest precision (up to IT6) and good surface finish ● Suitable for hard materials and high-precision requirements | ● Low efficiency ● High cost ● Suitable for high-end parts such as precision screws and gauges |

5. Surface Finishes for Pan Head Screw

| No. | Surface Finishes | Pictures | Features | Coating Thickness | Advantages | Disadvantages |

|---|---|---|---|---|---|---|

| 1 | Electrogalvanizing (White zinc, blue-white zinc, colored zinc, black zinc, etc.) |  | Immerses the screws in an electrolyte, where an electric current deposits a zinc layer on the surface | Typically 5-15μm | ● Low cost ● Diverse appearances (colored zinc, blue-white zinc, etc.) ● Good rust resistance, widely used | ● Thin coating (5-15μm) ● Limited corrosion resistance, easily affected by high temperatures |

| 2 | Hot-dip galvanizing |  | Screws are immersed in molten zinc to form a thick zinc coating | ≥30μm | ● Thick coating (≥30μm) with strong corrosion resistance ● Suitable for outdoor and coastal environments | ● Rough appearanc ● Reduced dimensional accuracy ● Unsuitable for small screws |

| 3 | Dacromet |  | Screws are dipped in a zinc-aluminum flake coating solution and then baked to cure | Typically 4-8μm | ● Excellent corrosion resistance (superior to electroplated zinc) due to its unique zinc-chromium composite structure ● High-temperature resistance, and environmentally friendly (no hydrogen embrittlement) | ● High cost ● Monochromatic appearance (silver-gray) ● Average surface finish |

| 4 | Black Oxidation |  | Screws are heated in a strong alkaline solution to form an oxide film | Typically 0.5-1.5μm | ● Low cost ● Attractive black surface ● Anti-glare | ● Poor rust resistance (must be oiled and sealed for rust prevention) ● Not resistant to highly corrosive environments |

| 5 | Phosphating (Gray phosphorus, black phosphorus) |  | A phosphate film forms on the screw surface | Typically 5-15μm | ● Strong adhesion ● Easy to apply oil or paint ● Good friction properties | ● Poor corrosion resistance alon, requires oil or coating |

| 6 | Paint |  | Paint or coating the screw surface | Typically 5-30μm | ● Offers a variety of colors, aesthetic appearance, and additional corrosion protection | ● Has weaker adhesion than plating, easily peels ● Not resistant to high wear |

| 7 | Electroplating Nickel/Chromium Plating |  | Electroplating deposits a nickel or chromium layer on the surface | ● Decorative nickel coatings: typically 0.5-5μm ● Corrosion-resistant nickel coatings: typically 5-15μm ● Wear-resistant nickel coatings: typically 10-50μm | ● Bright appearance ● Good wear resistance, hardness, and good corrosion resistance | ● High cost ● Risk of hydrogen embrittlement ● Requires additional process control |

| 8 | Electroplating Nickel/Chromium Plating |  | ● Decorative chrome plating: 1-3μm ● Wear-resistant chrome plating: 50-100μm | |||

| Pickling and passivation treatment for stainless steel screws | Typically 0.5-3μm | ● Maintains the metal’s natural color and improves corrosion resistance | ● Suitable for stainless steel ● Relatively high cost |

||

| 9 | Copper/Tin Plating |  | Electroplating deposits a copper/tin layer | Typically 0.5-10μm | ● Good electrical conductivity, used in electronics/electrical applications | ● Average corrosion resistance ● Medium cost |

| 10 | Carburizing/nitriding (Surface heat treatment) | / | Incorporates carbon or nitrogen into the surface at high temperatures | / | ● Improves surface hardness and wear resistance | ● Primarily improves mechanical properties; corrosion resistance is limited ● Require combination with other coatings |

6. Screw Inspection

| Table 4 – Screw Inspection | ||||

| No. | Stages | Inspection Items | Methods/Tools | Purpose |

| 1 | Incoming Quality Control (IQC) | Material Composition | Material Composition Report, Spectroscopic Analysis | Confirm that the material meets the requirements (e.g., carbon steel, stainless steel grade) |

| Mechanical Properties | Hardness Tester, Tensile Testing Machine | Check whether tensile strength and hardness meet standards | ||

| Appearance/Dimensions | Caliper, Thread Ring Gauge, Plug Gauge | Verify that the raw materials and head blanks conform to the drawings | ||

| 2 | In-Process Quality Control (IPQC) | Head Forming | Visual Inspection/Caliper | Confirm that the head is free of cracks and eccentricity |

| Threading | Thread Gauge, Measuring Projector | Check thread integrity, pitch, and thread angle | ||

| Surface Finish | Salt Spray Test, Film Thickness Gauge, Visual Inspection | Confirm uniform coating, no missing plating, and no bubbles | ||

| Torque/Tightening Performance | Torque Tester | Confirm that screw torque meets requirements to prevent thread stripping and breakage | ||

| Hydrogen embrittlement test (high-strength screws) | Delayed fracture test | Confirm that the surface treatment is free of hydrogen embrittlement | ||

| 3 | Final Quality Control (FQC) | Appearance Defects | Visual Inspection, Automated Optical Inspection (AOI) | Full inspection or random inspection to remove burrs, cracks, and shrinkage |

| Dimensional Consistency | Caliper, Thread Gauge | Random inspection to confirm batch stability | ||

| Salt Spray Test (corrosion protection) | Salt Spray Chamber | Confirm that the coating’s corrosion resistance meets standards (e.g., 48 hours, 96 hours, 500 hours) | ||

| Packaging Confirmation | Weighing and Quantity Counting Machine | Confirm quantity is correct and packaging meets customer requirements | ||

| 4 | Pre-shipment | Sampling Inspection | Sampling according to AQL standards | Control defect rate to ensure consistency |

| Test Report | Provide material certification and inspection report | Provide customer traceability | ||

Key Notes

- 100% inspection for critical dimensions (e.g., thread gauge inspection)

- Salt spray testing time is determined per customer requirements

- Xiamen Eternal Precision is equipped with Automated Optical Inspection and can do 100% defect inspection to guarantee the quality

7. How to Choose Right Screws for Your Product/Project?

1) ApplicationCheck

Purpose: Is the screw being used to secure structural components, decorative parts, or critical load-bearing areas?

Environment: Indoor/outdoor? Will it be subject to moisture, salt spray, chemical corrosion, or high temperatures?

Disassembly frequency: Will the screw need to be disassembled frequently? (For example, electronic products)

2) Screw Types

Wood → Wood screws, self-tapping threads, coarse threads for better engagement.

Sheet Metal → Self-tapping screws, self-drilling screws (can remove pre-drilling).

Plastic Parts → Specialized plastic screws (larger thread profile to prevent stress cracking).

Machinery/Thick Metal → Machine screws (with nuts or tapped holes).

3) Load & Strength

Static/Light Load: Regular carbon steel screws.

Heavy Load/Structural Components: High-strength bolts (Grade 8.8, 10.9, or 12.9).

Vibration/Shock Environment: With anti-loosening features (nylon locknuts, spring washers, and rubber-coated screws).

4) Surface Finishes/Material Selection

General Indoor Use: Zinc or nickel plating.

Wet/Outdoor Use: Stainless Steel (304, 316).

High Strength and Rust Resistance: Alloy Steel with Zinc-Nickel/Dacromet-Plated Surfaces.

High Aesthetics: Polished or Black-Oxide Stainless Steel.

5) Dimensions and Standards

Diameter and Length: Determined by the thickness of the connected part + the reserved screw-in length.

Thread Profile: Choose from metric (ISO), American (UNC/UNF), Japanese (JIS), etc., ensuring consistency with customer/design specifications.

Head Type: Pan head, countersunk head, internal hexagon, external hexagon, etc. → Depends on appearance requirements, installation space, and torque requirements.

6) Cost and Installation Efficiency

High-Volume Production → Prioritize standard parts for low cost and easy procurement.

Need for Quick Assembly → Use self-tapping, self-drilling, and self-locking screws to reduce the number of steps.

High Requirements for Easy Maintenance → Common head shapes (such as Phillips and hexagonal) are more suitable.

8. How Can Xiamen Eternal Precision Help You?

Xiamen Eternal Precision offers custom-made services to specialty fasteners with wide options for materials and surface finishes.

We can do 100% equipment inspection to guarantee more stable & consistent screw quality.

Packaging will be as per the customers’ requirements. Contact us to get a quick quote and start your projects.

9. People Also Ask

In most cases, electricians and installers prefer pan head screws because they save labor, time, and provide stability. Flat head screws are primarily used for aesthetics or for achieving a flush surface.

1) Pan Head Screws

Features: Slightly convex head with a large contact surface, less likely to damage the fastened component during tightening.

Advantages

- No countersinking required; simply screw in.

- Large bearing surface, suitable for pressing components.

- Easy to install with high efficiency.

Disadvantages

- The head is raised, making it unsuitable for flush or concealed surfaces.

2) Flat Head Screws

Features: Conical head allows for flush insertion into workpieces.

Advantages

- Smooth, aesthetically pleasing surface, no catching or scratching.

- Commonly used in areas where mounting is required (such as electrical equipment panels and woodworking furniture).

Disadvantages

- Must be countersunk beforehand, otherwise uneven force is applied.

- Small contact area, easily damaging the fastened component. Slightly weaker in strength than pan head screws.

Common Applications

Junction Boxes (JBs), Pipe Clamps, Brackets → Most electricians prefer pan head screws because:

- Quick assembly, no countersinking required.

- Better clamping force, suitable for metal or hard plastic parts.

Where a flush/aesthetically pleasing surface is required → Use flat head screws, such as furniture panels and visible decorative parts.

II. Why might one choose a button head screw over a pan head screw (and vice versa)?

The main differences between choosing a pan head or a button head screws are appearance + space required + load-bearing surface.

For your application, both are acceptable; the pan head is more secure, while the button head is more attractive.

1) Pan Head Screw

Appearance: The top is slightly flatter, with relatively upright edges, giving it a more “sturdy” appearance.

Force: The contact surface is larger than a button head, allowing for greater contact with the component when tightened, and providing better pull-out resistance.

Installation Space: Slightly taller, requiring more space.

Application: Commonly used in applications requiring stability and reliability, such as fastening metal parts.

2) Button Head Screw

Appearance: The top has a rounded transition, resulting in a softer shape and improved aesthetics.

Force: The head is lower than a pan head, resulting in a relatively smaller contact surface and slightly weaker strength.

Installation Space: The head occupies less height, making it suitable for applications where appearance or space are of paramount importance.

Applications: Commonly used in furniture, electronics, and other applications, they provide secure, yet resist snagging.

Your Demand: Desk frame + tabletop + threaded insert

- If you’re looking for stability and even load distribution → pan head screws are more suitable

- If you’re more concerned with appearance and don’t want the screws to protrude too high → button head screws are preferred

- The functional difference isn’t significant, as you’re tightening with the threaded insert, not relying on the head to withstand significant tension.