When you search titanium vs aluminum, you are usually stuck on a real project: a bracket, a frame, a housing, maybe even something like titanium glasses, a titanium knife, or a titanium bottle. Your customer wants “premium,” production wants something that machines well, and your boss wants a margin.

So the question is not which metal is “better,” but where it actually makes sense to pay for titanium, and where aluminum is the smarter choice. The same 3D model in titanium vs aluminum will behave differently in machining, in metal 3D printing, and in forming – and it will land in a very different price range.

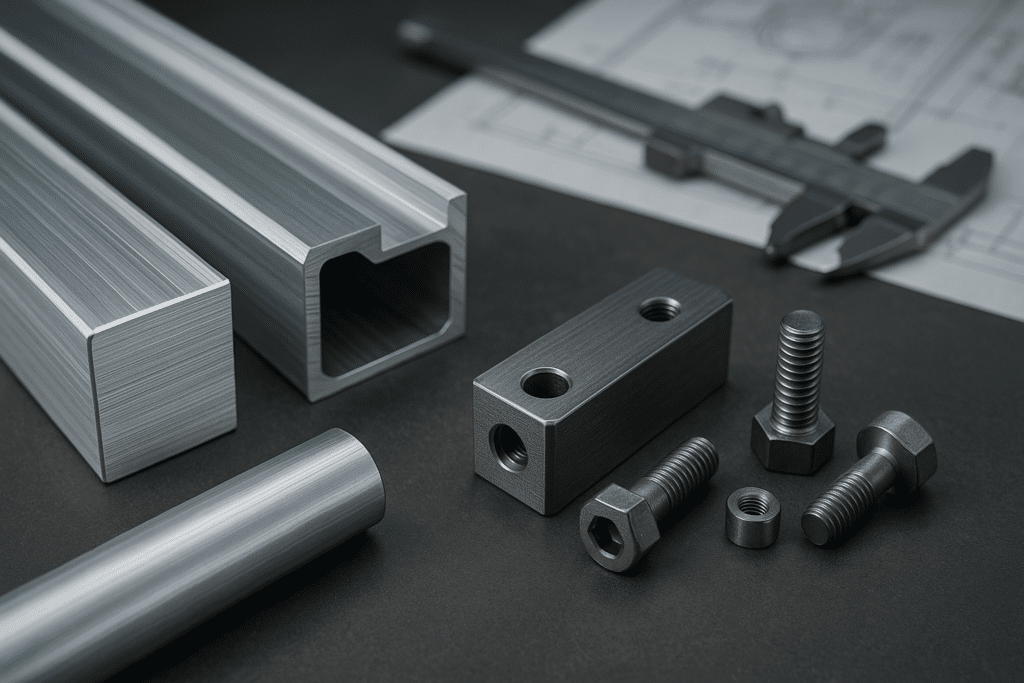

This article is written for engineers and buyers making those decisions every day. We look at titanium vs aluminum the way a supplier quotes parts: density and strength instead of hype, machining titanium vs machining aluminum instead of vague “hard to process,” with real examples from 8020 aluminum material frames, 6061 aluminum tubing and aluminum sheets metal, all the way to “titanium vs aluminum iPhone–style” housings.

1. Titanium vs Aluminum: Key Properties at a Glance

1) Weight

• Is titanium lighter than aluminum? No.

• Titanium is about 4.5 g/cm³, aluminum about 2.7 g/cm³. With the same geometry, a titanium part is heavier than an aluminum part.

2) Strength

• Many titanium alloys have a much higher tensile strength than common aluminum alloys.

• This is where the phrase “titanium is stronger than steel” comes from: some titanium grades can match or exceed the strength of typical steels at a much lower weight, while aluminum cannot reach those strength levels without adding a lot of material.

3) Stiffness (Deflection)

• Titanium has a higher elastic modulus than aluminum, so for the same cross-section it deflects less under load.

• In frames built from 8020 aluminum material, 6061 aluminum tubing or aluminum sheets metal, you often increase the section size to compensate for aluminum’s lower stiffness.

4) Corrosion Resistance

• Aluminum, combined with proper anodizing or coating, performs very well in many outdoor applications such as aluminum gutters, building facades and general hardware.

• Titanium’s passive oxide film is even more stable, which is why it is used in highly corrosive environments and in contact with body fluids, from chemical equipment to medical implants.

5) Magnetism

• Is aluminum a magnetic material? No, and titanium isn’t either.

• For most engineering purposes, both aluminum and titanium are essentially non-magnetic, which matters around sensors, medical imaging equipment and precision instruments.

Fun facts about titanium and aluminum

• Titanium you don’t notice

One of the most common fun facts about titanium: you see it every day without realizing it. Titanium dioxide is used as a white pigment in paints, plastics and even some sunscreens, so you probably “touch” titanium far more often than just holding a titanium knife or other visible titanium parts.

• Aluminum used to be a luxury metal

An unusual fact about aluminum: in the 19th century it was harder to produce than gold, so it was actually more expensive. Aluminum tableware was reserved for VIP guests, while everyone else had to settle for silver. The tip of the Washington Monument was originally made of aluminum as a showpiece “precious” metal.

• Fireworks and bright sparks

Finely divided titanium can create very bright white sparks when it burns, so titanium particles are used in fireworks and stage effects to get that extra-intense sparkle.

• Recycling champion

A large percentage of all aluminum ever produced is still in use today. Recycling aluminum uses only a small fraction of the energy needed to produce primary metal, which is why aluminum sheets metal, beverage cans and building profiles are recycled so aggressively worldwide.

2. Process View: Machining, 3D Printing and Forming Trade-offs

2.1 Machining Titanium vs Aluminum: Cycle Time, Tool Wear, and Surface Finish

On paper the drawing is the same. On the shop floor, machining titanium vs aluminum feels like two different jobs.

• Cutting data and heat management

Aluminum loves high cutting speeds and aggressive feed. Chips evacuate easily, heat goes into the chip, and cycle times are short.

Machining titanium needs much lower speeds, rigid setups and serious coolant. Titanium holds heat at the cutting edge, so tools suffer quickly.

• Tool life and cost per part

In aluminum, tools last a long time and you can group parts to keep spindles running all day.

In titanium, tool life is shorter, you change inserts more often, and you accept smaller step-downs and step-overs. Even with the same CAM strategy, cost per part climbs. This is why machining titanium, not just buying titanium, drives the quote up.

• Typical aluminum parts

Everyday CNC “work horses”: aluminum bolts, small brackets from aluminum sheets metal, profiles from 6061 aluminum tubing or 8020 aluminum material frames.

When volumes are medium to high and the market is price-sensitive, aluminum is almost always the first material we propose in CNC machining services.

• Typical titanium parts

Small, high-value components where strength, corrosion resistance or “premium feel” really matter: structural links, high-end housings, medical or aerospace parts.

Here the buyer is willing to pay for machining titanium, because the part carries the performance or brand story.

2.2 3D Printing: Titanium vs Aluminum for Additive Manufacturing

In metal additive manufacturing, the logic is similar but the numbers get bigger.

• When titanium powder makes sense

Titanium powders are more expensive and have a narrower process window, but they shine in high-load, high-temperature or safety-critical parts: aerospace brackets, topology-optimized structures, medical implants. You pay more, but you get strength, stiffness and corrosion resistance in complex shapes that would be hard to machine.

• When aluminum powder is smarter

Aluminum powders are ideal when you want lightweight parts at a lower cost: housings, covers, brackets and lattice structures where ultimate strength is not the limiting factor.

Very often, adjusting the geometry and staying with aluminum is cheaper than insisting on titanium and locking in a high cost per build forever.

If you are considering metal 3D printing for a titanium vs aluminum design, the real decision comes from geometry, loads, environment and budget together — not from the material name alone. That is exactly how we evaluate material options before quoting.

2.3 Profiles, Sheet & Forming: Why Aluminum Owns This Space

For long profiles, frames and general sheet metal, aluminum simply owns the space.

• Aluminum as the default

Aluminum extrudes into complex shapes, bends and forms well, and has mature anodizing and coating systems. That is why you see aluminum gutters on buildings, window and door profiles, 8020 aluminum material frames, and most general sheet metal guards or covers made from aluminum, not titanium.

• Why titanium rarely shows up here

Forming titanium is possible, but significantly harder and more expensive. Material cost is higher, forming limits are tighter, and most customers will not pay a premium when aluminum already meets strength, stiffness and corrosion requirements.

If you are designing doors, windows, industrial frames or equipment covers as a B2B customer, in 90% of real projects you will be talking to us about aluminum solutions. Titanium only enters the conversation when the environment or the branding truly demands it.

3. Design Trade-offs: Looking at Titanium vs Aluminum from a Product and Brand View

3.1 Premium Look & Feel: Titanium Glasses, iPhone, and Titanium Bottles

From a product manager’s view, titanium is often chosen to signal “premium,” not just to tick a strength box.

Due to their superior acoustic performance, this contrast is especially important in high-end musical instrument hardware design; please refer to our Precision CNC Machining for High-End Musical Instrument Components: Material & Finish Guide for details.

• High-end frames use titanium glasses because they are light, sweat-resistant and hypoallergenic. Customers see “titanium” on the spec sheet and accept a higher price.

• In a titanium vs aluminum iPhone–style decision, a brand pays more for titanium to get a stiffer frame and a more exclusive feel, but must balance that against yield, machining cost, battery space and thermal management.

• For outdoor gear, a titanium bottle or titanium knife is a classic “bragging rights” item: users know it is more expensive than aluminum and buy it partly for that story.

In all these cases, the brand is using titanium as a visible promise of durability and status, not just as a generic metal.

3.2 When Aluminum Is “Good Enough” and Much Smarter

Most products do not need that level of story. For mid-range electronics housings, laptops, everyday bottles and cookware, aluminum is already light, strong enough and easy to machine or form at scale.

You get clean surfaces, good thermal performance and low scrap cost, and you can run large volumes at stable pricing. For many B2B projects, the smartest move is to design well in aluminum, instead of forcing titanium into a part just to make the spec sheet look fancy.

4. Cost and Supply Chain: Paying for Titanium Where It Actually Matters

On a quote, titanium vs aluminum is not just a material choice, it is a cost structure.

• Material price and scrap

Titanium costs several times more per kg than aluminum. Scrap hurts more: off-cuts and chips are still valuable, but recycling and handling are more expensive.

Aluminum is cheap, easy to source and easy to recycle, so you can be more relaxed about nesting and buy in standard stock sizes.

• Process cost: machining titanium vs aluminum

Aluminum runs fast with long tool life and high spindle utilization.

Machining titanium needs slower feeds and speeds, more tool changes and heavier cooling. Even if the raw material cost was the same, the cost per part for machining titanium would still be higher.

• Volume and MOQ

Small batches of high-value parts are where titanium makes sense: the unit price is high anyway, and the part can carry that value (medical, aerospace, premium consumer).

When you are pushing volume and fighting for every cent, aluminum wins: stable supply, lower MOQ pressure, and predictable pricing on repeat orders.

• Surface finishing

Aluminum has a mature toolbox: clear or colored anodizing, powder coating, brushing, polishing. You get good wear resistance and a wide aesthetic range at low cost.

Titanium can be colored and textured too, but the processes are more specialized and less standardized, which again shows up in the quote.

The smart move in many projects is not “all titanium” or “all aluminum,” but a mix. Use aluminum for frames and non-critical structure, and reserve titanium for the few connectors or exposed parts where its properties and brand value actually move the needle.

5. Case: Aluminum Gutters and Covers – Corrosion Concerns Without Overkill

Background

An industrial customer needed long aluminum gutters and sheet metal covers for a processing line in a humid, slightly corrosive environment. They had heard stories about corrosion on cheap aluminum and were seriously considering switching the whole design to titanium.

Problem

Using titanium for every gutter and cover would:

• Multiply the material cost compared to standard aluminum alloys.

• Complicate forming and joining, because bending and welding titanium is not as straightforward as common aluminum sheet metal.

• Blow the budget on parts that were non-critical: if a cover corrodes after many years, it can be replaced; it is not a life-critical component.

They needed better durability, but “all titanium” was clear overkill.

Solution

We focused on getting aluminum right instead of changing metal:

• Selected a more suitable aluminum alloy and thickness for the gutters and sheet metal housings, with better corrosion resistance and stiffness.

• Specified a proven coating system: proper surface preparation, high-quality anodizing or powder coating tailored to their chemical exposure and cleaning routine.

• Adjusted a few design details (drainage, overlap, fastener locations) to avoid water traps and galvanic corrosion points.

Result

• The customer kept an aluminum-based solution at a fraction of the cost of titanium.

• Accelerated corrosion tests and field trials showed the new coated aluminum gutters and covers comfortably meeting their lifetime target.

• They got the reliability they wanted, without re-training their suppliers or operators on exotic titanium sheet metal fabrication.

6. Checklist: How to Decide Between Titanium and Aluminum for Your Next Custom Part

Use this as a quick filter before you lock in a material:

• How weight-sensitive is the part?

Is every gram critical, or is “reasonable weight” enough if the price is right?

• What is the service environment?

Dry indoor, outdoor, marine, sweat, body fluids, chemicals, high temperature?

(The harsher and more special the environment, the more titanium starts to make sense.)

• How strong is the “premium material” expectation?

Does the customer or brand need to see “titanium” on the spec sheet (titanium glasses, titanium bottle), or are they happy with a well-designed aluminum part?

• Annual volume and target unit price?

Small batches and high unit value can carry titanium; high volumes with tight pricing almost always push you toward aluminum.

• Which process will you use?

CNC machining, metal 3D printing, sheet metal, profiles/extrusions?

Some processes favor aluminum heavily on cost and lead time, especially for long profiles and general sheet metal.

• Any critical standards or regulations?

Medical, aerospace, or special certifications may effectively force a titanium vs aluminum choice.

• What is your surface and appearance requirement?

Do you need colored anodizing, special textures, or just a clean industrial finish?

If you do not want to run all these trade-offs yourself, just send us your drawing, expected volume and basic environment, and we can come back with a clear titanium vs aluminum comparison and a concrete quote.

7. Turn the Titanium vs Aluminum Trade-off into a Real Quote

At the end of the day, titanium vs aluminum is not a theory question – it is a sourcing decision. The same drawing can be a smart aluminum part, an overkill titanium part, or a balanced mix of both. Which one you end up with will decide your cost, lead time and how your product feels in the customer’s hand.

We work with both titanium and aluminum every day: CNC machining, profiles, and sheet metal parts. That means we do the trade-off with you instead of pushing only one material. If titanium really adds value, we will tell you where. If a well-designed aluminum solution is better for your volume and budget, we will tell you that too.

Send us your drawing, expected volume and basic environment, and we will do a free titanium vs aluminum review with:

• A clear recommendation on material and process

• A comparative quote so you see the impact on cost and lead time

From there you can decide if you want a titanium highlight, an optimized aluminum workhorse, or a mix of both for your next custom part.

Learn more about our capabilities and services: