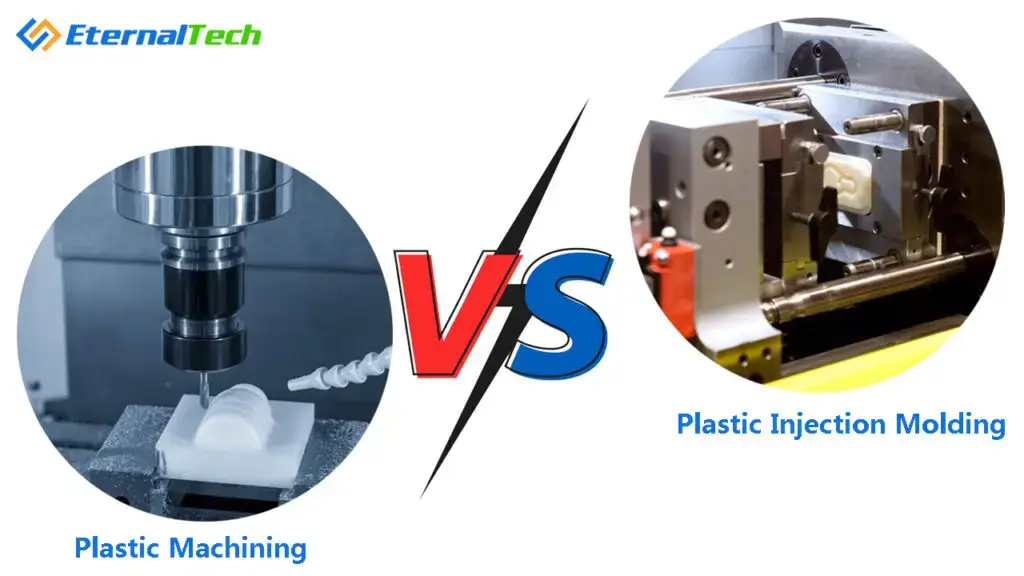

When companies need custom plastic parts – especially for medical device injection molding, high-precision components, or large industrial structures – the first challenge is choosing between plastic machining and plastic injection molding. Both methods can produce excellent parts, but each solves a different set of problems.

Below is a practical, experience-based guide designed to help buyers understand real-world limitations, avoid costly mistakes, and choose the right process with confidence.

What Is Injection Molding (Especially for Medical and High‑Volume Parts)

Injection molding melts resin and injects it into a steel mold cavity to form the final shape. In medical plastic injection molding and high precision injection molding, materials such as polycarbonate, HDPE, nylon, and polyethylene are widely used for their cleanliness, repeatability, and controlled performance.

Medical and industrial manufacturers prefer injection molding because:

● Tight tolerances can be repeated across millions of cycles

● Resin choices comply with medical and regulatory standards (injection molding medical plastics)

● Thermal behavior is predictable under controlled processing conditions

● Ideal for high-volume production of stable, consistent geometries

However, injection molding also carries risks such as short shot injection molding – where the cavity is not fully filled due to low temperature, insufficient pressure, poor venting, or highly viscous materials.

For additional insights on injection molding processes, check out our Kunststoff Spritzguss (Plastic Injection Molding) ↗article.

What Is CNC Plastic Machining

CNC plastic machining services use solid plastic blocks that are milled, turned, or routed into the desired geometry. This method is extremely effective for:

● Prototypes and engineering validation

● Low-volume production

● Complex designs without draft requirements

● Custom, precision machined plastic components

Materials like nylon, polycarbonate, acetal, PEEK, and medical-grade engineering plastics remain dimensionally stable during machining.

Unlike molding, machining allows unlimited design flexibility – engineers can modify the geometry at any time without reworking a mold.

Looking for CNC plastic machining services? Explore our CNC machining capabilities ↗ for prototypes and precision components.

Quantity: The First and Most Important Decision Factor

Many buyers make the wrong choice simply because they underestimate how much volume determines the manufacturing method.

Injection molding is ideal when you need:

● 20,000- 500,000+ pcs

● Repeatable parts with consistent performance

● The lowest long-term cost per unit

● The ability to amortize mold expenses over large production runs

This applies to polycarbonate injection molding, HDPE injection molding, nylon injection molding, polyethylene injection molding, and many other resins.

CNC machining is ideal when you need:

● 50- 2,000 pcs

● Flexible design changes

● Customized features per batch

● Faster delivery instead of lower unit cost

Design Flexibility: Machining Wins, Injection Molding Requires Commitment

Many customers assume they can freely modify a mold after it’s made. In reality, mold modifications often cost more than building the mold correctly from the start.

For injection molding:

● Modifying an existing mold requires extra cost and new lead time

● Adding ribs, removing holes, changing wall thickness, altering structure- all require steel rework

● Complex design changes may cost nearly as much as a new mold

For machining:

● Design updates are implemented instantly

● No additional tooling investment

● Ideal for medical startups needing prototypes before scaling to medical device plastic injection molding

Lead Time: Machining Ships in Days, Molding Takes Weeks to Months

Injection molding timeline

● Mold design: 5 – 14days

● Mold manufacturing: 30- 60 days

● Testing and revisions: 5 – 20 days

Total: at least 40 days

CNC machining timeline

● Programming + machining: 3- 10 days

● Ideal for urgent replacement parts or pilot builds

● Fast enough for clinical testing of medical devices

If a customer needs parts urgently, machining is the obvious choice.

Precision: Machining Achieves Higher Accuracy, Molding Offers High Repeatability

Injection molding accuracy is influenced by:

● Thermal expansion

● Shrinkage

● Resin flow patterns

● Cooling speed and mold design

Even with high precision injection molding, shrinkage variation must be considered.

CNC machining usually achieves higher tolerances because the material remains solid and stable.

At Xiamen Eternal Precision, our machined plastic parts routinely achieve ±0.01 mm tolerance.

Case

A German medical device manufacturer required a polycarbonate lens housing with ±0.02 mm concentricity. Injection molding variation was too high, causing assembly issues. Switching to machined polycarbonate components solved the problem immediately and reduced verification time by 40%.

For more best practices, tolerances, and material insights, see our full Plastic Machining Guidelines↗.

Surface Appearance: Machining Has No Gates, No Pins, No Flow Marks

Common molding defects include:

● Gate marks

● Ejector pin marks

● Weld lines

● Flow lines

● Cold slugs

Machined plastic parts avoid these issues entirely and can be polished, bead-blasted, or vapor-polished for clear polycarbonate components.

For cosmetic-critical parts (consumer electronics, medical housings, display units), machining offers more reliable appearance control.

Material Selection: The Most Common Source of Failure

Choosing the correct material determines whether the final part performs or fails in its application.

| Material | Best For | Notes |

| Polycarbonate injection molding | Medical housings, impact–resistant parts | High clarity, sterilization–friendly |

| HDPE injection molding | Chemical containers, lids, fluid systems | Low cost, tough, very moldable |

| Polyethylene injection molding | Consumer & industrial parts | Good flow, good chemical resistance |

| Nylon injection molding | Gears, bushings, wear parts | Absorbs moisture; design compensation required |

| Medical injection molding | Plastics diagnostics, fluid handling, testing | Must meet biocompatibility + traceability standards |

A proper injection molding material selection guide prevents costly redesigns and performance failures.

For Plastic Machining:

UHMW-PE is a commonly machined material in industrial applications. Here’s a full guide on machining UHMW↗.

Nylon is another frequent choice for gears and wear components. Read our in-depth guide on machining Nylon (Polyamide)↗.

Large Part Injection Molding vs Machining

Producing large components introduces new challenges:

● Extremely high clamping force required

● Molds for large parts can be prohibitively expensive

● Higher risk of short shot injection molding

● Machining large sheets or blocks is often faster and cheaper

For medical carts, diagnostic panels, or large housings, customers often ask:

Thermoforming vs Injection Molding – Which Is Better?

● Thermoforming: cheaper for large, low-volume covers

● Injection molding: better for durable, high-volume parts

● Machining: best for low-volume or customized structural components

Case: Why a US Medical Manufacturer Switched from Injection Molding to Machining

A U.S. medical device company initially used injection molding for a polycarbonate diagnostic housing.

They encountered:

● High mold cost

● Along development cycle

● Warpage during cooling

● Frequent short shots due to thin ribs

Switching to machined plastic components instantly solved their problems:

● Zero mold investment

● 1-week turnaround

● Perfect flatness

● No short shots

● Simple design updates

Their final product launch was accelerated by three months.

Conclusion

Choosing between medical device injection molding, plastic machining, or thermoforming depends on:

● Production volume

● Budget

● Required precision

● Structural complexity

● Cosmetic expectations

● Material behavior

At Xiamen Eternal Precision, we provide both machined plastic parts and injection molding solutions under one roof.

Send us your drawings anytime – we’ll help you evaluate feasibility, materials, costs, and the best manufacturing method for your product.

Need help choosing the right process or material? Visit our Plastic Parts manufacturing page↗ to see how we support low to high-volume production needs.