Struggling with UHMW melting, burrs, or holding tolerances? Our definitive guide reveals proven CNC parameters, tool selection, and fixture strategies to machine UHMWPE successfully.

Who This Guide Is For

– CNC Machinists & Programmers facing UHMW’s unique challenges

– Mechanical Design Engineers specifying plastic components

– Procurement Specialists sourcing precision plastic parts

– Manufacturing Engineers optimizing production processes

– Students & Educators in materials science and manufacturing

Why UHMW Machining Frustrates Even Experienced Machinists

UHMWPE is a miracle polymer—incredibly tough, wear-resistant, and self-lubricating. But for machinists, it can be a nightmare. Its tendency to melt rather than cut, spring back after machining, and produce fibrous burrs has ruined many a tight-tolerance part.

If you’ve ever asked, “Why can’t I hold dimensions on UHMW?” or watched helplessly as your workpiece developed a gummy, melted surface—you’re not alone.

The secret lies in understanding that UHMW doesn’t machine like metals or even like most other plastics. Its extremely high molecular weight and unique viscoelastic properties demand a completely different approach. This guide translates UHMW’s tricky material properties into actionable, step-by-step machining strategies used by top plastics fabricators, so you can produce perfect parts every time.

What is UHMW?

UHMW (Ultra-High Molecular Weight Polyethylene) is a thermoplastic polymer with molecular weights typically between 3.5 and 7.5 million atomic mass units. This extremely high molecular weight gives UHMW its remarkable properties but also makes it challenging to process using conventional methods.

Material Properties: Pros & Cons

UHMW Properties – Advantages

1) Excellent Wear Resistance

– 3 to 7 times higher wear resistance than carbon steel

– One of the most wear-resistant plastics available

– Ideal for high friction and abrasive environments

2) Self-Lubricating

– Friction coefficient: 0.05-0.11

– 50% lower than PA6 when water lubricated

– Second only to PTFE in dry conditions

– Reduces maintenance costs in sliding applications

3) Outstanding Impact Resistance

– Maintains toughness at cryogenic temperatures (-200°C)

– Highest impact energy absorption of all plastics

– Excellent noise damping characteristics

– Perfect for high-impact applications

4) Chemical Stability

– Resists acids, alkalis, and most solvents (except concentrated nitric acid)

– Stable performance from 20°C to 80°C

– Widely used in corrosive industrial environments

5) Low Temperature Performance

– Maintains mechanical properties down to -80°C

– Suitable for freezing and cryogenic applications

UHMW Properties – Limitations

1) Manufacturing Challenges

– Poor melt flow characteristics

– Requires special high-temperature, high-pressure equipment

– Higher production costs compared to standard polyethylene

2) High Thermal Expansion

– Coefficient of thermal expansion: 150-200 × 10⁻⁶/°C

– Poor dimensional stability with temperature fluctuations

– Challenging for high-precision applications

3) Limited Heat Resistance

– Maximum continuous service temperature: 80-100°C

– Susceptible to degradation at elevated temperatures

– Not suitable for high-temperature environments

4) UV Sensitivity

– Degrades under prolonged sunlight exposure

– Requires UV stabilization for outdoor use

– Becomes brittle with UV degradation

5) Poor Adhesion

– Low surface energy makes bonding difficult

– Requires special surface treatments for adhesives

– Challenging for composite manufacturing

6) Low Hardness & Strength

– Lower hardness than engineering plastics like acetal or nylon

– Not suitable for high-load applications

– Limited structural applications

UHMW Applications by Property

Property | Applications |

Wear & Impact Resistance | • Textile machinery: shuttles, gears, buffers |

Self-Lubricating | • Bulk handling: hopper liners, chutes |

Chemical Stability | • Chemical processing: seals, pump parts |

Low Temperature | • Cryogenic equipment |

Process Selection Guide

✅ Recommended Processes

CNC Machining (Most Common)

– Best for: Prototypes, low-volume production, complex geometries

– Tools: Carbide or diamond-coated cutters with large rake angles

– Parameters: Low speed (≤200 m/min), shallow DOC (0.1-0.3mm), fast feed

– Cooling: Compressed air only (water causes swelling)

– Accuracy: ±0.1mm achievable with proper technique

Pressure Sintering

– Best for: Simple shapes, high-volume blanks

– Process: Powder compression under heat and pressure

– Advantages: Good material properties, cost-effective for simple parts

Hot Compression Molding

– Best for: Sheets, plates, simple formed parts

– Process: Heating followed by press forming

– Applications: Liners, large wear plates

❌ Not Recommended

Injection Molding

– Extremely high melt viscosity

– Requires specialized, expensive equipment

– Limited to very simple shapes

Extrusion

– Similar challenges to injection molding

– Limited to simple profiles

Laser Cutting

– Causes melting and uneven edges

– Produces toxic fumes

– Poor edge quality

CNC Machining UHMW: Common Defects & Solutions

Defect Type | Cause | Solution |

Surface Melting/Burning | • Excessive cutting heat | • Use sharp, carbide/diamond tools |

Burrs/Fibrous Edges | • Material toughness causes tearing | • Use new tools for finishing passes |

Dimensional Instability | • Elastic recovery (0.1-0.3mm typical) | • Multi-stage machining with cooling periods |

Surface Chatter/Roughness | • Tool vibration | • Use short, rigid tool holders |

Proven Best Practices from Industry Experts

1. Tool Selection Strategy

– Roughing: 2-flute end mills for efficient material removal

– Finishing: Single-flute spiral mills to minimize cutting forces

– Drilling: 90-118° point angles with polished flutes

– Diamond-coated tools: Worth the investment for production runs

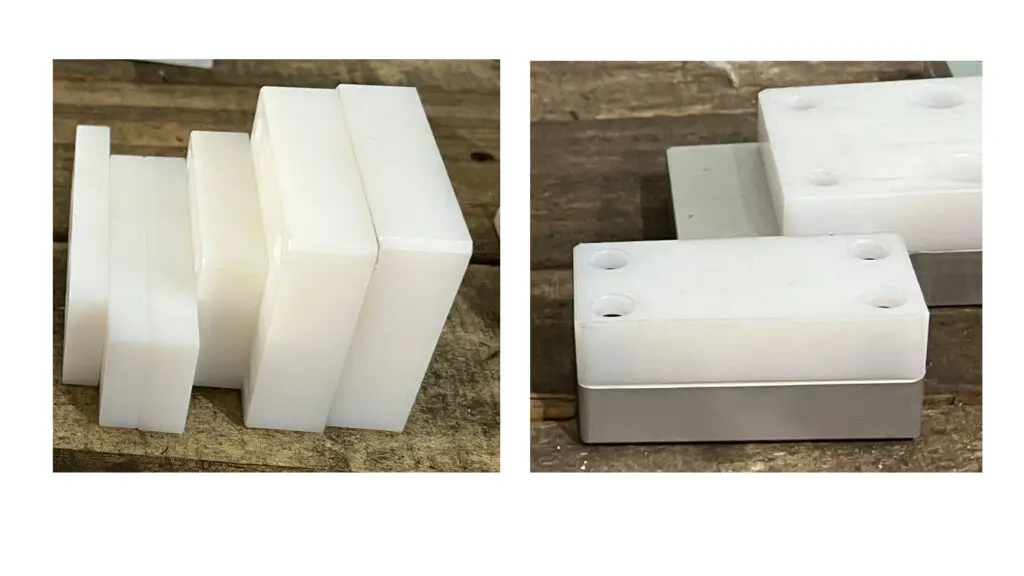

2. Clamping & Fixturing

– Avoid: Direct metal-to-UHMW contact

– Use: Soft rubber pads to distribute pressure evenly

– Recommended: Vacuum fixtures for thin sections

– Alternative: Double-sided tape for small parts

3. Parameter Optimization

ROUGHING:

- Speed: 150-200 m/min

- Feed: 0.15-0.25 mm/tooth

- DOC: 0.3-0.5 mm

- Stepover: 50-60% of tool diameter

FINISHING:

- Speed: 200-250 m/min

- Feed: 0.1-0.15 mm/tooth

- DOC: 0.1-0.2 mm

- Stepover: 10-20% of tool diameter

4. Case Study: Deep Pocket Machining

Challenge: A customer needed 50mm deep pockets with ±0.1mm tolerances and smooth sidewalls.

Solution Applied:

- Used 3xD long-series carbide end mills

- Implemented trochoidal milling paths

- Applied compressed air through spindle

- Roughing with 0.4mm DOC, finishing with 0.15mm DOC

- Final pass: 0.05mm DOC at 300 m/min

Result: Achieved required tolerances with Ra 1.6µm surface finish.

5. Emergency Defect Recovery

– Melted surface: Scrape with sharp blade, re-machine at lower speed

– Oversized dimensions: Localized heating (≤80°C) with heat gun for adjustment

– Excessive burrs: Dry ice treatment followed by trimming

– Warped parts: Annealing at 70°C for 2-4 hours

UHMW vs Other Engineering Plastics

Property | UHMW | HDPE | Nylon 6/6 | Acetal (POM) | PTFE |

Wear Resistance | ⭐⭐⭐⭐⭐ | ⭐⭐ | ⭐⭐⭐ | ⭐⭐⭐⭐ | ⭐⭐ |

Impact Strength | ⭐⭐⭐⭐⭐ | ⭐⭐⭐ | ⭐⭐ | ⭐⭐ | ⭐ |

Chemical Resistance | ⭐⭐⭐⭐ | ⭐⭐⭐⭐ | ⭐⭐ | ⭐⭐⭐ | ⭐⭐⭐⭐⭐ |

Machinability | ⭐⭐ | ⭐⭐⭐⭐ | ⭐⭐⭐ | ⭐⭐⭐⭐⭐ | ⭐⭐⭐ |

Cost | $$$ | $ | $$ | $$ | $$$$ |

Best For | Wear parts, impact | General use, low cost | Gears, bearings | Precision parts, low friction | Chemical, high temp |

When to Choose UHMW:

– Extreme wear applications (conveyor components, guides)

– Impact-resistant parts (bumpers, protective liners)

– Low-friction, self-lubricating applications

– Chemical exposure environments (excluding strong oxidizers)

– Cryogenic to moderate temperature ranges

Frequently Asked Questions

1. What is the cost premium for machining UHMW vs HDPE?

UHMW typically costs 20-40% more to machine than HDPE due to:

– Specialized tooling requirements

– Longer machining times (multiple passes needed)

– Higher scrap rates during learning curve

– Additional finishing operations

2. Can UHMW be tapped for threads?

Yes, but with special considerations:

– Tap type: Use spiral-pointed taps for through holes, spiral-fluted for blind holes

– Hole size: Oversize by 0.05-0.1mm compared to standard tap drill sizes

– Speed: Very slow (5-10 SFM) with frequent chip clearance

– Alternative: Use threaded inserts for stronger, more reliable threads

3. How do I achieve tight tolerances (±0.05mm) with UHMW?

– Machine in temperature-controlled environment (20±2°C)

– Implement multi-stage machining with 24-hour stabilization between stages

– Use diamond-coated tools for final passes

– Apply statistical process control for production runs

– Consider annealing after rough machining

4. Is UHMW food-safe and FDA compliant?

– Virgin UHMW: FDA compliant for food contact (FDA 21 CFR 177.1520)

– Regrind material: May not be compliant

– Colorants: Must be food-grade approved

– Applications: Widely used in food processing equipment

5. How do I bond or weld UHMW parts?

Adhesive Bonding:

– Requires surface activation (flame, corona, or plasma treatment)

– Use two-part epoxy or specialized polyethylene adhesives

– Surface energy must be raised from 31 dynes/cm to >45 dynes/cm

Welding:

– Hot plate welding produces strongest joints

– Vibration welding suitable for certain geometries

– Requires specialized equipment and parameters

Key Takeaways for Success

1. Heat Management is Critical: Low speeds, fast feeds, and air cooling prevent melting

2. Sharp Tools are Non-Negotiable: Dull tools guarantee poor results

3. Expect Springback: Design in 0.1-0.3mm compensation for critical dimensions

4. Patience Pays Off: Multi-stage machining with cooling periods yields best results

5. Fixturing Matters: Avoid distortion with proper clamping techniques

Further Reading & Resources

Plastic Machining vs Plastic Injection Molding: How to Make the Right Decision for Your Application

Machining Nylon (Polyamide): A Plastics Guide

Bronze Machining: A Comprehensive Guide

Need Professional Assistance?

If you’re facing specific challenges with UHMW parts or need expert machining services:

– Upload your drawings for instant quotation

– Request material samples for testing

– Schedule a consultation with our engineering team

– Visit our learning hub for more technical resources

Contact our engineering team today to transform your UHMW challenges into manufacturing successes.

Quick Action Items for Your Next UHMW Project

1. Before Machining:

– Order extra material for test cuts

– Prepare sharp, dedicated UHMW tools

– Design fixtures with minimal clamping pressure

2. During Setup:

– Start with conservative parameters

– Implement forced air cooling

– Plan for multiple finishing passes

3. After Machining:

– Allow 24 hours for dimensional stabilization

– Measure critical features after stabilization

– Document successful parameters for future reference

Remember: UHMW rewards patience and attention to detail. Follow these guidelines, and you’ll join the ranks of machinists who have mastered this challenging but rewarding material.