1. What is Kunststoff Spritzguss (Plastic Injection Molding)?

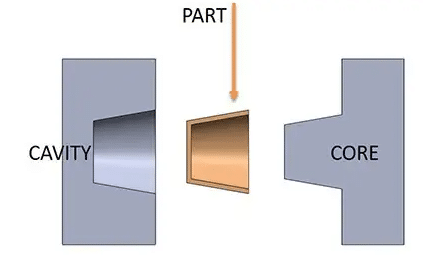

● Kunststoff Spritzguss: a German term, which means plastic injection molding

● Plastic Injection Molding: inject molten plastic into a steel mold under high pressure, and then cool it to create plastic parts

2. Kunststoff Spritzguss (Plastic Injection Molding) Manufacturing Process

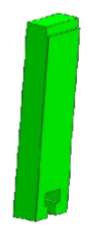

2.1 Product Design and Analysis

● Create 3D based on product requirements and check structural rationality

● Notes:

– Ensure uniform wall thickness, as it determines the product’s strength, weight, assembly, etc

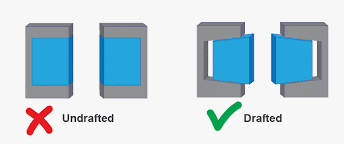

– Design a reasonable demoulding angle

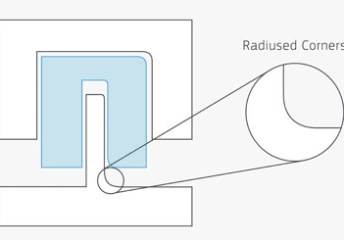

– Avoid sharp corners and use arc transitions

– Perform DFM (Design for Manufacturing analysis)

2.2 Mold Design and Building

● Design the mold structure according to the product

● Notes:

– Optimize the layout of the cooling water channel

– Consider the ejection

– Choose suitable mold steel (such as P20, 718, NAK80, S136 etc.)

2.2.1 P20 Steel

► A high-quality low-alloy cold-working die steel

► Usually used to produce medium-sized and medium-sized injection molds

► Has high hardness, good processing performance and good heat treatment performance

2.2.2 718 Steel

► A nickel-based alloy steel

► Has high hardness, corrosion resistance and thermal stability

► Excellent wear resistance and high temperature strength

► Suitable for making high-demand injection molds

2.2.3 NAK80 Steel

► High-strength, high-toughness

► Good thermal fatigue resistance and cold fatigue resistance

► A good choice the high-speed injection molds and high-precision injection molds

2.2.4 S136 steel

► Excellent corrosion resistance, high hardness and high wear resistance

► Good processing performance and stability

► Used to fabricate high-quality and high-precision injection molds

2.3 Mold Installation and Commissioning

● Install the mold on the injection molding machine

● Notes:

– Make sure the mold matches the injection molding machine

► The mold should be able to be installed within the working area of the injection molding machine, leaving enough space for operation

► Ensure the parameters (such as maximum injection volume, injection pressure, clamping force etc) can meet

mold requirements

► Mold should be convenient to install and remove

– Check mold levelness

– Set the appropriate mold opening and closing stroke

2.4 Baking Materials

● Bakehygroscopic materials

● Notes:

– Materials like nylon and PC need baking to remove moisture before injection molding

► Nylon: usually bake at 80℃ to 120℃ from 4h to 6h

► PC: usually bake at 100℃ to 120℃ from 2h to 4h

► Use a drying hopper to keep the material dry

2.5 Mold Closing

● The mold closes to form a cavity

● Notes:

– Set appropriate clamping force

– Check whether the mold is completely closed

– Prevent mold displacement

2.6 Plasticization

● The plastic melts in the barrel

● Notes:

– Set appropriate temperature (varies for different materials)

– Control screw speed

– Prevent material degradation

2.7 Injection

● Inject molten plastic into the mold

● Notes:

– Control injection speed (to prevent jetting)

– Set reasonable injection pressure

– Ensure complete filling

2.8 Holding Pressure

● The screw rod continues to apply pressure to compensate for material shrinkage after the melt plastic has filled the mold cavity

● Notes:

– Set appropriate holding pressure

– Control holding time

– Prevent internal stress caused by excessive holding pressure

2.9 Cooling

● The part solidifies in the mold

Notes:

– Ensure sufficient cooling time

– Control cooling water temperature (usually 20-35℃)

– Check whether the cooling system is unobstructed

2.10 Mold Opening

● Notes:

– Set a reasonable mold opening speed

– Check whether the mold opening sequence is correct

2.11 Ejection

● The part is ejected from the mold

● Notes:

– Set a suitable ejection speed and stroke

– Prevent ejection from stress mark or penetration

– Check whether the ejector pin is smooth

2.12 Post-Treatment

● Perform subsequent treatment on the part

● Notes:

– Clean the surface before painting/electroplating etc

– Control the process parameters

– Check the treatment effect

2.13 T0 Sample

● First mold trial sample

● Notes:

– Check all dimensions

– Perform functional testing

– Record all problems

2.14 Mold Modification

● Modify the mold according to T0 sample problems

● Notes:

– Focus on the problems

– Keep the mold reference unchanged

– Record the modifications

2.15 Mold Trial

● Test the mold again after modification

● Notes:

– Verify the modification effect

– Optimize process parameters

– Check parts improvement

2.16 T1 Sample

● The second mold trial sample

● Notes:

– Check key dimensions

– Evaluate appearance quality

2.17 Sample Testing

● Conduct a comprehensive test on the sample

● Notes:

– Use professional testing tools

– Perform according to the inspection standards

– Record test data

2.18 Sample Approval

● Customer confirms and approves the sample

● Notes:

– Ensure full compliance with requirements

– Obtain written confirmation

– Keep approved samples

2.19 Mass Production

● Formal batch production

● Notes:

– Maintain process stability

– In-line process inspection

– Record production data

2.20 Quality Inspection

● Quality control of production process

● Notes:

– Establish inspection standards

– Focus on key dimensions

– Handle abnormalities promptly

2.21 Assembly and Packaging

● Product packaging and assembly

● Notes:

– Assemble parts according to requirements

– Choose appropriate packaging materials

– Proper product protection

– Clear and accurate labeling

2.22 Shipment

● Product delivery to customers

● Notes:

– Check shipping quantity

– Check packaging integrity

– Keep shipping records

Key Control Points

● Design stage: DFM analysis and mold design determine 80% of the quality

● Mold trial stage: T0-T1 is the key period for discovering problems

● Mass production stage: process stability and quality control are the key points

● Special materials: pay attention to drying and process parameter adjustment

3. What Materials Can Be Injection Molded?

| Table 1 – Injection Molding Materials and Their Applications | ||||

| Materials | Feastures | Applications | Industries | Notes |

| PA (Nylon) | ● High strength ● Wear resistance ● Heat resistance | ● Gears ● Bearings ● Power tool housings ● Auto parts ● Fishing reels | ● Automobiles ● Electronic appliances ● Machinery ● Sports equipment | ● Prone to absorb water ● Must be dried |

| PE (Polyethylene) | ● Flexible ● Chemical corrosion resistant | ● Daily necessities: buckets, washbasins ● Packaging containers ● Pipe fittings ● Toys | ● Packaging ● Daily necessities ● Agriculture ● Building materials | ● Categorized into HDPE/LDPE ● Large shrinkage rate |

| PS (Polystyrene) | ● Transparent ● Easy to process ● Brittle | ● Disposable tableware ● CD boxes ● Stationery ● Toy parts | ● Packaging ● Daily necessities ● Stationery | ● Prone to crack ● Not suitable for load-bearing parts |

| HIPS (High Impact Polystyrene) | ● Better impact resistance than PS | ● Home appliance housing: refrigerator liner ● Electronic product packaging ● Toys | ● Home appliances ● Electronics | ● Improve the brittleness of PS ● Still need to avoid high loads |

| PMMA (Polymethyl methacrylate) | ● High transparency ● Weather resistance | ● Optical lenses ● Lampshades ● Signs ● Bathroom accessories | ● Optics ● Advertising ● Construction ● Medical | ● Prone to be scratched ● Special polishing required |

| PVC (Polyvinyl chloride) | ● Flame retardant ● Corrosion resistant | ● Pipes ● Wire sheaths ● Medical catheters ● Door and window profiles | ● Building materials ● Medical ● Wires and cables | ● Stabilizers need to be added during processing to avoid high-temperature decomposition |

| PP (Polypropylene) | ● Lightweight ● Chemical resistance | ● Food containers ● Car interiors ● Medical syringes ● Household goods | ● Food packaging ● Automobiles ● Medical ● Home | ● Large shrinkage, need to optimize mold design |

| PC (Polycarbonate) | ● High transparency ● high toughness | ● Bulletproof glass ● Mobile phone housing ● Eyeglass lenses ● Car lampshades | ● Electronics ● Automobiles ● Optics ● Medical treatment | ● Must be dried ● Prone to stress cracking |

| PPO (Polyphenylene oxide) | ● High temperature resistance ● Dimensional stability | ● Electronic connectors ● Car dashboards ● Water pump parts | ● Electronics ● Automobiles | ● Often blended with PS for modification |

| EC (Ethyl cellulose) | ● Flexible ● Oil-resistant | ● Tool handles ● Eyeglass frames ● Sporting goods | ● Tools ● Sports equipment | ● Narrow processing temperature range |

| POM (Polyoxymethylene) | ● High rigidity ● Self-lubricating | ● Gears ● Bearings ● Zippers ● Sprayer parts | ● Machinery ● Automobiles ● Daily necessities | ● Prone to release formaldehyde ● Good ventilation required |

| PSF (Polysulfone) | ● High temperature resistance ● Transparent | ● Medical devices ● Aircraft interior parts ● Electronic insulation parts | ● Medical ● Aerospace ● Electronics | ● High processing temperature (300-380℃) |

| ABS (Acrylonitrile Butadiene Styrene) | ● Good comprehensive performance ● Easy processing | ● Home appliance housing: TV, printer ● Toys ● Automotive accessories | ● Home appliances ● Toys ● Automobiles ● 3D printing | ● Need to control the melt temperature (200-240℃) |

4. Injection Molding Advantages, Disadvantages and Process Variations

4.1 Advantages

● High Production Efficiency

– Short cycle time

– Suitable for mass production

– High degree of automation

● Complex Structure Molding

– Can produce precision parts: such as threads, buckles, thin-walled parts

– One-time molding

● Material Diversity

– Applicable to most thermoplastics (such as ABS, PC, PA, etc.) and some thermosetting plastics

● Good Surface Quality

– Can mold high-gloss and textured surfaces, reducing post-treatment

● Low Scrap Rate

– Runner and gate materials can be recycled and reused (especially hot runner technology)

● Dimensional Stability

– High product consistency through pressure holding and cooling control

4.2 Disadvantages

● High Mold Cost

– The cost of developing steel molds is high (tens of thousands to millions)

– Small batch production is not cost effective

● Design Limitations

– It must meet the injection molding process requirements: such as draft angle and wall thickness uniformity

● Large Equipment Investment

– Large injection molding machines are expensive and have high maintenance costs

● Complex Process Debugging

– Adjust parameters: temperature, pressure, cooling

– Mold trial lead time is long

● Internal Stress Problems

– Improper process may cause part warping and cracking (especially materials such as PC)

● Material Limitations

– Some high-performance plastics (such as PEEK) are difficult to process and need special equipment

4.3 Process Variations

4.3.1 Regular Injection Molding

Definition: The basic injection molding process, inject molten plastic into the mold to create the part

Features:

● Single material, single color molding

● Mature and stable process

● Relatively simple mold structure

Applications:

● Most common plastic products

● Such as daily necessities, electrical housings, plastic parts, etc

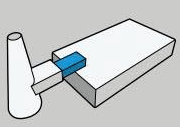

4.3.2 Insert Injection Molding

Definition: Place metal inserts or other materials in the mold, and combined with plastic after injection molding

Features:

● Realize a composite structure of metal and plastic

● Requires precise insert positioning

● Can enhance local strength or function

Applications:

● Plastic parts with metal threads

● Electronic connectors

● Automotive assemblies

4.3.3 Two-Color Injection Molding

Definition: Use two plastics of different colors, or different materials to create a part

Features:

● Requires a special two-color injection molding machine

● Complex mold structure

● Can achieve a combination of soft and hard plastics

Applications:

● Multi-color buttons

● Toothbrush handles

● High-end electronic product housings

4.3.4 Micro-Foam Injection Molding

Definition: Inject supercritical fluid (such as nitrogen) into the plastic melt to form a microporous foaming structure

Features:

● Weight decreased by 10-20%

● Reduce internal stress and warping

● Need to accurately control the foaming process

Applications:

● Automobile lightweight parts

● Large plastic products

● Structural parts that need to be reduced in weight

4.3.5 NMT – Nano Molding Technology

Definition: Nano-treat the metal surface, and then inject the molten plastic onto the metal surface

Features:

● Metals need to be specially treated first

● High bonding strength

● Can achieve metal-plastic integration

Applications:

● Mobile phone metal frame

● High-end electronic product structural parts

● Automobile lightweight parts

| Table 2 – Injection Molding Process Comparison | ||||

| Process | Features | Advantages | Typical Applications | Equipment |

| Regular injection molding | Single-material molding | Low cost, high efficiency | Regular plastic parts | Standard injection molding machine |

| Insert injection molding | Metal-plastic combination | Enhanced partial performance | Electronic connectors | Need insert positioning |

| Two-color injection molding | Dual material combination | Beautiful and multifunctional | Electronic products | Two-color injection molding machine |

| Micro-foam injection molding | Microporous foaming | Lightweight and weight reduction | Automotive parts | Foaming device required |

| NMT – Nano Molding Technology | High metal bonding | Metal-plastic integration | Mobile phone frame | Surface treatment required |

5. Considerations for Injection Molding

5.1 Draft Angles and Radii

Ensure smooth demolding of plastic parts, reduce wear and deformation

● Key points:

– Draft angle: Typically 1°~3°, deep cavity or rough surface needs to be increased (such as 3°~5°)

– Radius (rounded corners): Avoid sharp corners to reduce stress concentration (recommended radius ≥ 0.5 times wall thickness)

5.2 Wall Thickness

● Uniform wall thickness to avoid shrinkage, warping and insufficient filling

● Recommended value:

| Table 3 – Recommended Wall Thickness | ||||

| Materials | Minimum Wall Thickness / mm | Recommended Wall Thickness for Small Plastic Parts / mm (Maximum external dimensions <80.0mm) | Recommended Wall Thickness for Medium Plastic Parts / mm (Maximum external dimensions range from 80.0mm to 200.0mm) | Recommended Wall Thickness for Large Plastic Parts / mm (Maximum external dimensions >200.0mm) |

| PA (Nylon) | 0.45 | 0.75 | 1.6 | 2.4 ~ 3.2 |

| PE (Polyethylene) | 0.6 | 1.25 | 1.6 | 2.4 ~ 3.2 |

| PS (Polystyrene) | 0.75 | 1.25 | 1.6 | 3.2 ~ 5.4 |

| HIPS (High Impact Polystyrene) | 0.75 | 1.25 | 1.6 | 3.2 ~ 5.4 |

| PMMA (Polymethyl methacrylate) | 0.8 | 1.5 | 2.2 | 4 ~ 6.5 |

| PVC (Polyvinyl chloride) | 1.15 | 1.6 | 1.8 | 3.2 ~ 5.8 |

| PP (Polypropylene) | 0.85 | 1.45 | 1.75 | 2.4 ~ 3.2 |

| PC (Polycarbonate) | 0.95 | 1.8 | 2.3 | 3 ~ 4.5 |

| PPO (Polyphenylene oxide) | 1.2 | 1.75 | 2.5 | 3.5 ~ 6.4 |

| EC (Ethyl cellulose) | 0.7 | 1.25 | 1.9 | 3.2 ~ 4.8 |

| POM (Polyoxymethylene) | 0.8 | 1.4 | 1.6 | 3.2 ~ 5.4 |

| PSF (Polysulfone) | 0.95 | 1.8 | 2.3 | 3 ~ 4.5 |

| ABS (Acrylonitrile Butadiene Styrene) | 0.75 | 1.5 | 2 | 3 ~ 3.5 |

● Notes:

– The cooling time depends on the thicker part of the wall, uneven wall thickness will extend the cycle time and reduce production efficiency

– Too large wall thickness: it’s susceptible to generating vacuum voids inside and shrinkage depressions outside, and also causes long cooling time and increases material costs

– Too small wall thickness: the molten plastic has a large flow resistance, making it difficult to fill the mold, which also cause poor strength and rigidity

– Thickness changes need to be smooth transition (slope ≤1:3)

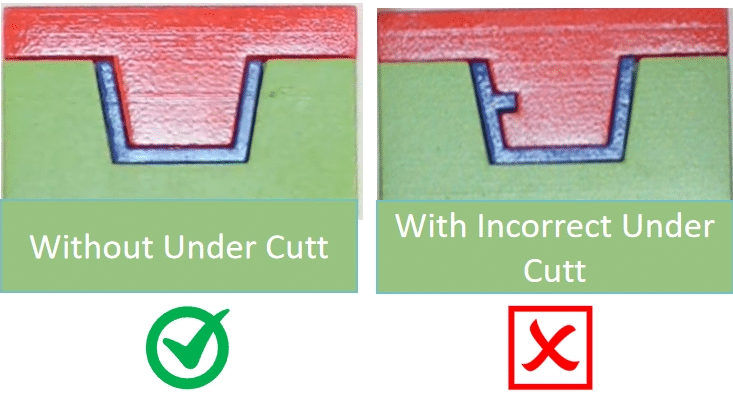

5.3 Core Pulling and Ribbing

Core Pulling Design:

● Used for side holes, undercuts or concave structures on molded plastic parts to avoid being unable to release the mold

● Common Core Pulling Mechanisms:

– Slider Core Pulling: Suitable for side holes or outside undercuts, pulled by inclined guide columns or hydraulic cylinders

– Inclined Ejectors (Inclined Ejector Core Pulling): Good choice for inside undercuts, using the oblique movement of the ejector plate to complete core pulling

– Hydraulic/Pneumatic Core Pulling: Used for long-distance or complex core pulling, with high precision but high cost

● Design Points:

– Core pulling stroke = undercut depth + safety margin (usually +2~3mm)

– Sliders and inclined ejectors need to be equipped with wear-resistant blocks (such as bronze or self-lubricating materials) to reduce wear

– Avoid conflicts between the core pulling direction and the mold opening direction to prevent mold interference

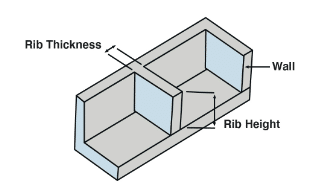

Ribbing Design

● Improve the rigidity of plastic parts, reduce wall thickness, and prevent deformation

● Design Principles:

– Thickness: The root thickness of the rib is ≤ 60% of the part wall thickness (such as 2mm part wall thickness and 1.2mm rib thickness) to avoid shrinkage marks

– Height: ≤ 3 times the part wall thickness. Too high may lead to insufficient filling or ejection deformation

– Draft Angle: Typically 0.5°~1.5°, deep ribs need to increase the angle (such as 1.5°~2°)

– Root Fillet: R = 0.25T~0.5T (T=part wall thickness) to reduce stress concentration.

● Layout Optimization:

– Use cross grid or radial layout to improve overall strength

– Avoid the rib position facing the gate to prevent weld marks from affecting strength

5.4 Mold Core/Cavity

● Material Selection:

– Mold steel (such as P20, H136) is commonly used for cavity/core, and cemented carbide is used for long lifetime requirements

● Surface Treatment:

– Use mirror polishing (roughness Ra≤0.2μm) or coating treatment (such as titanium nitride TiN, diamond-like coating DLC) to improve surface hardness (HV≥2000) and wear resistance, and reduce the risk of melt retention and mold sticking

– For transparent products, the cavity surface must be optical polishing to avoid melt surface defects (such as flow marks and uneven gloss)

● Cooling System:

– Evenly arrange water channels, 10~15mm away from the cavity surface to avoid partial overheating

5.5 Undercuts

● Solution:

– Lateral Core Pulling: Apply sliders or inclined ejector mechanisms for complex undercuts

– Forced Demoulding: Elastic materials (such as PP) can be designed with elastic deformation zones

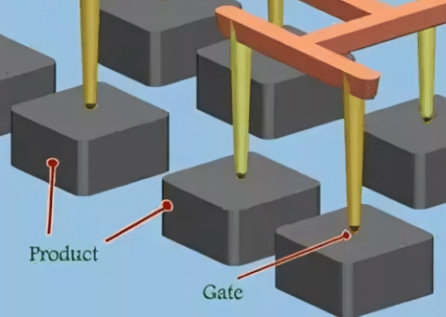

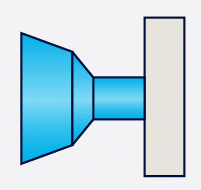

5.6 Gate

Gate: also known as the feed port, is the channel connecting the runner and the cavity, which affects the melt flow, molding quality and appearance

5.6.1 Common Injection Molding Gate Types & Features

| Gate Types | Pictures | Features | Applications | Advantages | Disadvantages |

|---|---|---|---|---|---|

| Edge Gate |

| ● Located at the edge of the parting line ● Rectangular or fan-shaped cross-section | ● Most common plastic parts: such as shells, boxes | ● Easy to process ● Widely applicable | ● Requires manual trimming ● May leave marks |

| Pin Gate |

| ● Small diameter (0.5~1.5mm) ● Automatic cutting | ● Appearance parts: such as mobile phone cases, transparent parts | ● Automatic cutting ● Good appearance | ● Large pressure loss ● Three-plate mold required |

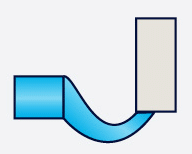

| Tunnel Gate/Submarine Gate |

| ● Submarine obliquely under the parting line ● Automatically cut off when ejected | ● Internal hidden gate: such as home appliance parts | ● No post-treatment required | ● Complex design ● Prone to wear |

| Fan Gate |

| ● Wide and thin fan-shaped cross section ● Uniform feeding | ● Flat parts: such as panels, thin-walled parts | ● Reduce flow stress | ● Large gate residue |

| Ring Gate |

| ● Plastic is injected around the cylindrical part | ● Tubular parts: such as pen holders, bottle caps | ● No weld marks | ● Much waste ● Post-treatmentg required |

| Overlap Gate |

| ● The gate is located on the parting line ● Typically rectangular | ● Suitable for multi-cavity molds: small and medium-sized plastic parts | ● Easy to process ● Flexible selection of gate position ● Easy to remove gate | ● Venting difficulty ● High pressure loss |

| Sprue Gate |

| ● The sprue supplies plastic directly to the part ● The sprue is attached to the part | ● Thick wall or high stress parts: such as handles | ● Good filling | ● Large residue ● Need to be trimmed |

| Cashewgate/Banana Gate |

| ● From the runner to the part connection, it is curved like a banana | ● Products with high requirements for appearance quality and structural strength ● Like automotive parts, electronic product housings, household appliances, etc | ● Simple structure ● Small flow resistance ● Easy gate removal | ● Difficult to process ● Higher mold cost |

5.6.2 How to Select the Correct Gate Position/Location

I. Appearance (Gate Marks & Weld Lines)

Gate Marks:

● For appearance parts (such as mobile phone cases and transparent parts), pingates or submarine gates are preferred to reduce visible gate residues

● Avoid setting gates on high-gloss surfaces, otherwise shrinkage marks or uneven gloss are likely to occur

Weld Lines:

● Weld lines should avoid appearance surfaces or high-stress areas (such as buckles and threads)

● Move weld lines to non-critical areas (such as the back of ribs) by adjusting the gate position or increasing the number of gates

Optimization:

● Use fan gates or multi-point injection to make the melt fill evenly and reduce weld line strength issues

● CAE analysis (such as Moldflow) simulates the weld line position and optimizes the gate layout in advance

II. Part Function

Structural Strength:

● Gates should not be set in high-stress areas (such as assembly holes and buckles) to avoid fractures caused by weld lines

● Thick-walled areas are suitable for locating gates to help pressure maintenance and shrinkage compensation, also to reduce shrinkage holes

Assembly Impact:

● Avoid gates affecting mating surfaces or sealing surfaces (e.g., gates for waterproof parts should be away from joints)

Optimization :

● For gears, bearings and other load-bearing parts, use ring gates or multi-point injection to ensure uniform filling and avoid unilateral stress concentration

III. Mold Machining

Feasibility:

● The gate position should be convenient for mold machining, and avoid being set in deep cavities or narrow areas, which will cause processing difficulties

● The gate should be located on the parting line as much as possible to facilitate the cleaning of the gate during mold processing and use

● The three-plate mold (pin gate) is more complex in structure and more expensive than the two-plate mold (edge gate), check whether it is necessary

Mold Lifetime:

● The gate should not be directly opposite to the small core or slider, otherwise long-term injection will easily lead to erosion and wear

Optimization:

● Preferably choose standard gates (such as edge gates) to reduce the processing difficulty caused by special structures

● Avoid using pin gates for high-glass fiber materials (such as PA+GF) to prevent the gate from wearing too quickly

IV. Prevent Warping

Unbalanced Flow:

● Single-side gates can easily lead to asymmetric shrinkage and warping(e.g., long parts should be injected at both ends)

● Multi-point gates or fan gates are recommended for thin-walled parts to ensure uniform filling

Cooling Effect:

● Set the gate position near the cooling water channel to avoid deformation caused by partial overheating

Optimization:

● Symmetrical layout of gates (e.g., 4-point glue injection for box-type parts) to balance shrinkage stress

● Combined with mold temperature analysis, ensure uniform cooling of the gate area

V. Gate Removal

Automated Production:

● Submarine and point gates can be automatically cut off, which is suitable for unmanned production

● Edge and sprue gates need to be manually trimmed, which increases post-treatment costs.

Residue of Gate Removal:

● Gate design should consider the aesthetics, such as hiding the fracture surface of submarine gates as much as possible on the inside

Optimization:

● For appearance parts, automatic gate cutting design (such as three-plate mold point gate) is preferred

● For manually trimmed gates (such as edge gates), reserve trimming margin to avoid damage to the product

5.7 Ejection

Ejection: smoothly release the cooled and solidified plastic parts from the cavity or core

5.7.1 Common Ejector Systems and Their Applications

| Ejector Types | Pictures | Features | Applications | Advantages | Disadvantages |

|---|---|---|---|---|---|

| Pin Ejector |

| ● Round/square ejector pin ● High degree of standardization | ● Most flat or simple curved plastic parts | ● Low cost ● Easy processing | ● Local stress concentration |

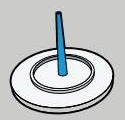

| Sleeve Ejector |

| ● Sleeve structure ● Inner core fixed ● Outer tube ejection | ● Deep cavity columnar structure (such as bottle mouth, BOSS column) | ● Stable demoulding of deep cavity | ● Complex machining |

| Air Ejection | ● Compressed air blows out plastic parts | ● Thin-walled deep-cavity parts: such as cup-shaped products | ● No ejection marks | ● Need air path system support | |

| Push Plate Ejection |

| ● The whole plate pushes the part to be released | ● Large flat thin-walled parts: such as box covers, trays | ● Uniform force | ● Complex mold structure |

| Inclined Ejector |

| ● Angle ejector block with core pulling function | ● Inner undercut structure: such as buckle, inner groove | ● No slider required | ● Risk of motion interference |

5.7.2 Ejector System Design

I. Ejector Balance

● Ejector pins/ejector blocks need to be laid out symmetrically to avoid product warping caused by unilateral force (e.g., rectangular parts need at least 4 ejection points)

● The ejector force point should be close to the area with the greatest demoulding resistance (e.g., BOSS column, bottom of deep rib)

II. Ejector Position Selection

● Eject at parts with high structural strength such as reinforcing ribs, bosses, thick-walled areas

● Avoid ejecting at the exterior surface or thin-walled area to prevent white ejection marks or cracking (e.g., transparent parts need to use air ejector or push plate)

III. Ejector Stroke Calculation

● Minimum stroke = part demoulding height + safety margin (typically +2~5mm)

● Deep cavity parts need to check the aspect ratio of the ejector pin (generally ≤10:1 to prevent bending)

IV. Matching Clearance Control

● Single-side clearance between ejector pin and hole:

General:

– Small diameter ejector: the single-side clearance is usually 0.005mm to 0.01mm for an ejector with a diameter of 2mm

– Larger diameter ejector: for an ejector with a diameter of more than 6mm, the single-side clearance can be increased to 0.015mm to compensate for the dimensional changes caused by thermal expansion

High-Precision Mold:

– For high-precision molds (such as optical or medical device molds), the single-side clearance needs to be reduced to within 0.003mm, and use nitriding or titanium plating to reduce the friction coefficient

V. Key Points

1) Anti-Stuck and Lubrication

● The ejector needs to be provided with a guide section (length ≥ 2 times the diameter), and the sleeve ejector needs to be equipped with a wear-resistant copper bushing

● High friction areas (such as inclined ejectors) should be designed with oil grooves or use self-lubricating materials (such as graphite copper)

2) Ejector Reset Safety

● A pre-reset mechanism (such as spring + micro switch) must be set to prevent the ejector from not returning when the mold is closed and causing collision

● The inclined ejector mechanism needs to verify the mold closing interference (through CAD motion simulation).

3) PartAdaptability

● Soft materials (such as TPU) need to increase the ejector contact area (using flat ejectors or ejector blocks) to reduce the risk of puncture

● The ejection speed of high-gloss parts needs to be controlled slowly and in sections (adjusted by the ejection program of the injection molding machine)

4) Venting and Cooling

● The ejector arrangement needs to avoid the cooling water channel, but it can also serve as an auxiliary venting channel (ejector gap venting)

● When ejecting a large area (such as a push plate), a heat dissipation slot needs to be added on the back of the ejector plate to prevent thermal deformation

5.8 Mold Lifetime

How to Increase Mold Lifespan

5.8.1 Mold Design

I. Optimize Structural Design:

● Design the mold structure to avoid stress concentration. For example:

– At the corners and thin walls of the mold where stress concentration is likely to occur, use rounded corner transitions and add reinforcing ribs to improve the strength and stability

– For molds with complex structures, a block design can be used to facilitate processing and maintenance

II. Select Suitable Materials:

● Choose suitable mold materials according to the use requirements and working conditions. For example:

– For molds with high hardness and high wear resistance, select Cr12MoV and H13 etc

– For molds that require corrosion resistance, use stainless steel

III. Cooling System:

● Design reasonable cooling water channels to ensure uniform cooling of all parts of the mold to avoid deformation or cracking due to excessive temperature difference

● The diameter, length, spacing and other parameters of the cooling water channel should be optimized according to factors such as the size, shape and material of the mold

5.8.2 Machining

I. Improve MachiningAccuracy:

● Use advanced equipment and processes to improve the mold machining accuracy and surface quality

● For mold key parts, such as the cavity, core, parting surface, etc., fine processing and polishing should be carried out to reduce friction and wear

II. Heat Treatment:

● Perform appropriate heat treatment, to improve the mold hardness, strength, wear resistance and toughness

● Control heat treatment parameters according to the mold material and use requirements to ensure the heat treatment effect

5.8.3 Use and Maintenance

I. Process Parameters:

● Set process parameters based on mold material, structure and part features

● The clamping force should be moderate

● Adjust injection pressure and speed based on the part shape and size to avoid excessive pressure and speed from impacting the mold

● Control mold temperature within a suitable range to avoid overheating or overcooling

II. Regular Clean and Lubrication:

● After each production, clean mold (such as plastic residue, flash, burrs, etc.)to prevent these impurities from scratching or corroding the mold

● Lubricate and maintain regularly mold moving parts, such as ejector pins, guide pins, sliders, etc

● Use lubricants (such as high-temperature grease)to ensure the smooth operation of the moving parts and reduce wear

III. Inspection and Maintenance:

● Regularly check mold, including mold appearance and dimensions, etc. to promptly detect defects (such as wear, deformation, cracks, etc.)

● Some wearing parts(such as ejector pins, guide pins, sealing rings, etc.) should be replaced regularly to ensure the normal mold operation

6. Post-Treatment

Some molded parts require further treatment to improve their aesthetics, functionality, durability. There are a variety of surface treatment depending on the material, application and customer requirements.

6.1 Mechanical Treatment

6.1.1 Polishing

● Enhance gloss, often used for high-gloss mirror plastic parts

● Applications

– Transparent parts: PC/PMMA optical components

– High-gloss home appliance panels

6.1.2 Sandblasting

● Change the surface texture of the workpiece to improve mechanical properties and fatigue resistance

● Remove the sharp edges and burrs on the workpiece

● Applications

– Automotive interior parts

– Anti-slip pattern on tool handles

6.2 Chemical Treatment

Electroplating (Physical Vapor Deposition / Water Plating)

● Offer the plastic surface a metallic texture, improve the grade and conductivity

● Type:

– Physical Vapor Deposition (PVD): Suitable for decorative plating, such as metallic luster

– Water plating: Can offer conductivity, but only suitable for conductive materials or treated plastics

● Applicable plastics

– ABS, PC+ABS, etc. (PP, PE are more difficult to electroplate)

6.3 Coating Treatment

6.3.1 Painting

● Enhance the appearance color, feel, wear resistance, and improve the overall texture

● Can achieve a variety of visual effects such as high gloss, matte, metal, pearlescent, etc

● High requirements on the surface, need to remove burrs and polish flat

● Common Coatings

– Regular paint, rubber oil, metallic paint, UV oil, etc

● Applicable Materials

– ABS, PC, PP (need to be processed), PA, etc

6.3.2 UV Coating

● Paint a high-hardness transparent protective layer on the surface

● Enhance wear resistance and scratch resistance

● Improve surface gloss and hardness

● Quick curing, environmentally friendly

● Applications

– Auto parts, instruments, compact discs, credit cards, window films, and automotive headlights and lighting components

6.4 Special Surface Treatment

6.4.1 Laser Engraving (Laser Marking)

● Remove the surface coating through laser to form a clear graphic mark

● Clear pattern, not easy to wear

● Suitable for surface treatment after painting (such as black oil and white text)

● Applications

– Digital product keyboard, instrument panel symbols, key backlight

6.4.2 Silk Screen Printing / Pad Printing

● Printing LOGO, patterns, text, etc. on plastic surfaces

● Applications

– Electronic products, home appliance panels, buttons, instruments, etc.

● Differences:

– Silk screen printing: Suitable for small flat and curved parts, thick and wear-resistant ink

– Pad printing: Can be printed on irregular curved surfaces, with higher precision

6.4.3 Water Transfer / Thermal Transfer

● Cover the pattern on the plastic surface by water or thermal transfer

● Clear patterns, can achieve special effects such as wood grain, carbon fiber, camouflage, etc

● Water transfer: Suitable for irregular surfaces, such as water bottles, helmets and other shells

● Thermal transfer: Suitable for regular surfaces, such as electronic panels and decorative surfaces

6.4.4 Etching (Leather Grain)

● Etching the mold to provide the injection molded parts with leather grain, frosted grain, cloth grain and other textures

● Avoid fingerprints and scratches, and improve texture

Note: This is a mold processing technology, but it affects the surface state of the final product

7. Common Injection Molding Defects and Measures

| No. | Defect | Pictures | Features | Causes | Measures |

|---|---|---|---|---|---|

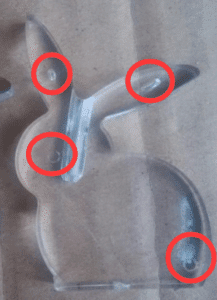

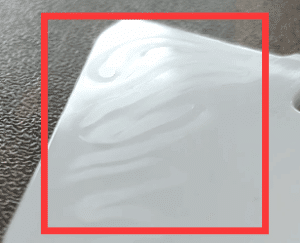

| 1 | Sink Marks |

| ● Partial depression on the part surface, mostly on the back of thick walls or ribs | ● Insufficient holding pressure or time, insufficient shrinkage compensation ● The melt temperature is too high, and the cooling shrinkage is too large ● The wall thickness design is uneven, and the wall thickness is too thick in some places | ● Increase the holding pressure and holding time ● Reduce the melt temperature and optimize the cooling system ● Improve the design to avoid sudden changes in wall thickness (such as using gradual transition) |

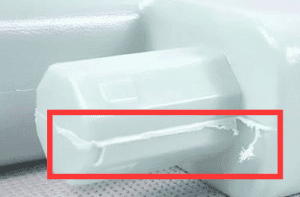

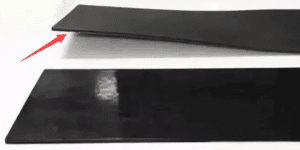

| 2 | Flash |

| ● Extra plastic in the form of flakes overflowing from the mold parting surface or insert gap | ● Insufficient clamping force or loose mold closure ● Injection pressure is too high or the melt fluidity is too good (such as too high temperature) ● Mold wear or insufficient processing accuracy | ● Increase clamping force or repair mold mating surface ● Reduce injection pressure, melt temperature or use high viscosity material ● Check mold wear regularly |

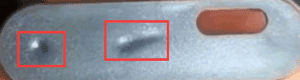

| 3 | Vacuum Voids |

Voids | ● Holes appear inside or on the part surface | ● The melt plastic contains gas (volatiles or air) ● Cooling too quickly, the surface solidifies and the inside shrinks to form a vacuum | ● Increase back pressure and improve the venting system (such as adding venting grooves) ● Reduce injection speed to avoid air inclusion ● Pre-dry hygroscopic materials (such as PA, PET) |

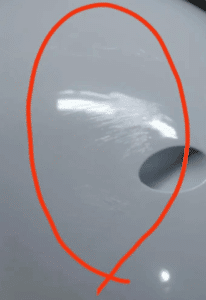

| 4 | Flow Marks |

| ● Wavy or radial lines appear on the surface | ● The melt plastics flow front cools too quickly, and the fluidity decreases ● The injection speed is too slow or the mold temperature is too low | ● Increase the injection speed or mold temperature ● Optimize the gate position and shorten the flow path ● Use a material with better fluidity |

| 5 | Silver Streaks |

| ● Silver streaks appear on the surface | ● Material degradation (overheating or long residence time) ● Water or volatile matter vaporization | ● Strictly control drying conditions ● Reduce melt temperature or shorten residence time ● Clean the screw rod and barrel to avoid impurities |

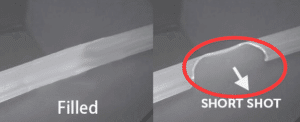

| 6 | Short Shot |

| ● The melt plastics does not completely fill the cavity | ● Insufficient injection volume or pressure ● Excessive flow resistance (gate is too small, mold temperature is too low) ● Poor venting causes gas to hinder filling | ● Increase injection volume, pressure or speed ● Enlarge gate or runner size and increase mold temperature ● Improve venting design |

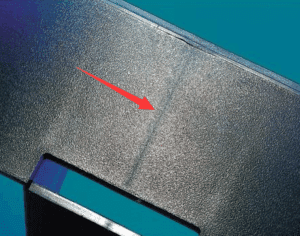

| 7 | Weld Lines |

| ● Thin lines formed at the intersection of melts | ● The temperature is too low when the front edges of multiple melts meet ● The gate position or number is unreasonable | ● Increase the mold temperature or melt temperature ● Adjust the gate position or increase the number of gates ● Add venting grooves in the weld mark area |

| 8 | Warpage |

| ● The part bends or twists after cooling | ● Uneven cooling (such as large temperature difference between the upper and lower molds) ● Anisotropic shrinkage (such as fiber-reinforced materials) | ● Optimize the cooling system to ensure uniform cooling ● Adjust the holding pressure or extend the cooling time ● Design ribs or symmetrical structures to balance shrinkage |

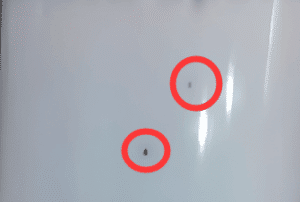

| 9 | Black Specks |

| ● Black impurities appear on the part surface or inside | ● Material degradation or contamination (such as burnt material remaining on the screw rod) ● Mold or barrel not cleaned properly | ● Lower melt temperature to avoid overheating ● Clean the screw rod and mold regularly ● Use materials with better thermal stability |

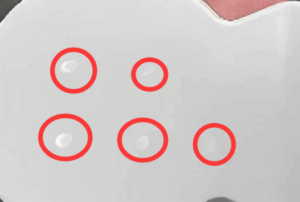

| 10 | Ejector Marks |

| ● The areas of ejector pin are white or bulging | ● Excessive demoulding force or too fast ejection speed ● Insufficient cooling, the part is too soft | ● Increase the number or area of ejectors and reduce the ejection speed ● Extend the cooling time or reduce the mold temperature ● Optimize the drfat angle or surface polishing |

8. Conclusions

As a mature manufacturing technology, injection molding has been widely used in automobiles, electronics, medical treatment, consumer products, etc.

Despite the maturity of the technology, defects can still occur in production due to slight changes in materials, processes, molds or equipment. This is where Xiamen Eternal Precision comes in – work with us to solve your problems.

Feel free to reach out to us.