Nylon is not a truly waterproof material – it absorbs moisture and changes dimension over time – but with the right grade, design and process control it can perform very reliably in wet or humid environments.

This article is written for mechanical engineers, product designers and buyers who are working with CNC machined, injection molded, extruded or 3D-printed nylon parts.

We’ll look at how nylon actually behaves in contact with water, how different nylon grades respond to moisture, and how smart design and processing choices can improve the water resistance and long-term stability of your nylon components.

1. What “Waterproof” Actually Means in Nylon Component Design

When we talk about nylon being “waterproof” in an engineering context, we need to be precise.

Waterproof usually means a part can withstand water at a defined pressure and for a defined time with zero leakage.

Water-resistant means the part can handle splashes, rain, wash-down or condensation, but it is not designed for long-term immersion.

Moisture-absorbing describes what nylon itself does: the polymer takes up water, its dimensions grow and its mechanical properties change over time.

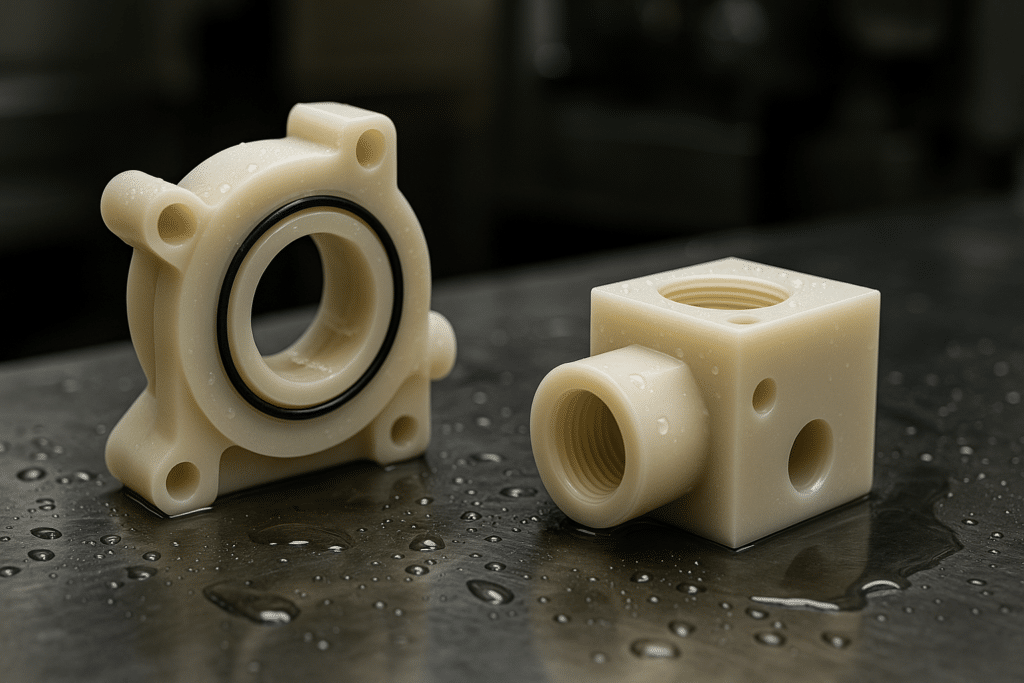

For real parts, these definitions translate into very different expectations. A “waterproof” nylon pump housing, valve body, connector or enclosure must keep liquid out under pressure.

A “water-resistant” nylon component in a humid workshop, outdoor rain or cold equipment with constant condensation only needs to survive occasional water contact while staying within acceptable dimensional and performance limits.

2. Nylon Grades and How They Behave in Moisture

In real projects you are not using some generic “nylon”. You are usually choosing between a few common engineering grades, each with its own moisture behavior:

| Nylon Grade | Typical use | Moisture Absorption | Dimensional Change | Mechanical effect |

| PA6 | General mechanical parts, housings, gears. | Relatively high | Noticeable swelling after conditioning | Stiffness drops, toughness increases in humid conditions |

| PA66 | Higher temperature, higher load parts | Similar to or slightly lower than PA6 | Clear growth in size if exposed to humidity or water | Modulus decreases, impact resistance improves somewhat |

| PA6/66 blends | Compromise between PA6 and PA66 in processability and properties | Medium range | Still visible, but often a bit more controlled | Moderate drop in stiffness when fully conditioned |

| PA12 | Tubes, fittings, parts that live in wet or outdoor environments | Low compared with PA6/PA66 | Much smaller swelling in service | Properties remain more stable over time |

| PA610 (and similar long-chain nylons) |

Where low moisture uptake and good toughness are both important | Low to medium | Limited growth, good dimensional stability in humidity | Stiffness and strength are more stable than PA6/PA66 |

| Glass-reinforced versions of the above | Structural parts with higher load and tighter tolerances | The polymer still absorbs water, but the glass fibers do not | Swelling is reduced and warpage is better controlled | Higher stiffness overall, less sensitive to humidity changes |

In engineering, the real question is not simply “is nylon waterproof?”, but whether a specific nylon grade, after it has absorbed moisture in your real working environment, still stays within acceptable dimensional change and property change for that part and that application.

3. How Different Manufacturing Processes Affect Nylon in Wet Environments

3.1 Injection-molded nylon parts

Even with the same nylon grade, injection-molded parts don’t behave like machined blocks or extruded profiles.

Poor cooling, short shots, weld lines and voids

• These defects create hidden capillaries and weak spots where water can track and leak.

Wall thickness and rib design

• Uneven wall thickness and aggressive ribs cause differential shrinkage and warpage, which can open up sealing surfaces over time.

When pellets are not dried properly

• Moisture in the pellets flashes into steam during molding, leading to bubbles, silver streaks and lower density – all bad for long-term sealing and strength.

After molding water uptake

• After molding, nylon absorbs moisture and expands. Critical dimensions on sealing faces, snap fits and press fits can shift, changing how “waterproof” the assembly really is.

3.2 CNC-machined nylon blocks, plates and bushings

Machining gives you tight tolerances, but only if you understand what happens after the part sees humidity.

Dry-state machining vs. wet-state use

• Parts cut to perfect size while bone-dry will grow once they reach moisture equilibrium, especially on large cross-sections.

Tools, coolants and sealing surfaces

• Tool wear, chatter and aggressive feeds leave marks that can become micro-leak paths on sealing faces.

• Water-based coolants can accelerate moisture uptake during machining itself, so surface finish and dimensional checks should consider that.

3.3 Extruded nylon profiles and tubes

Extrusion is great for long, continuous parts, but water and humidity still matter.

Length stability, ovality and wall control

• Line speed, cooling and puller settings drive straightness, ovality and wall thickness uniformity. Any deviation can compromise gasket compression or press-fit joints after the part absorbs moisture.

Assembly with metals and other materials

• When extruded nylon is clipped or pressed into aluminum, steel or other plastics, its moisture-driven swelling can either improve sealing or create stress and leaks if no allowance was made in the joint design.

3.4 3D-printed nylon parts

Additive nylon behaves differently again, mainly because of porosity and layer bonding.

Internal porosity and layer lines

• SLS, MJF and FDM nylon parts often have micro-pores and layer gaps that let water wick into the structure much faster than in molded or machined parts.

Moisture before and after printing

• Powder or filament that is not properly dried can cause weak, porous parts; after printing, the part itself will also absorb moisture and change size.

When extra steps are needed

• For demanding wet or splash environments, 3D-printed nylon usually needs sealing steps such as infiltration, coating or a secondary machined sealing surface to reach reliable water resistance.

4. Choosing Nylon Grades and Processes for Wet Conditions

A nylon part doesn’t need the same material and process for light humidity as it does for pressurized water. A simple way to decide is to start from the real moisture exposure, then pick grade + process together.

4.1 Define the moisture level

Light humidity only

• Indoor, humid air, occasional condensation

Occasional splashes / wash-down

• Short contact with water, then time to dry

Long-term contact with water

• Parts sitting in water or very wet environments for days or weeks

Pressurized water / fluid

• Pumps, valves, housings and fittings under pressure or high flow

4.2 Match nylon grade to the exposure

Light humidity / occasional splashes

• PA6 or PA66 are usually fine if you can tolerate some dimensional growth.

• Use glass-filled PA6/PA66 when you need better shape control and higher stiffness.

Long-term wet or dimension-sensitive parts

• Prefer low-absorption grades such as PA12 or PA610 to limit swelling.

• Glass-reinforced PA12/PA610 helps keep profiles, housings and flanges stable.

Pressurized water or critical sealing

• Low-absorption nylon grades + careful sealing design + glass reinforcement where stiffness is critical.

• Always check if the required pressure / leak rate is realistic for nylon before committing.

4.3 Choose the right process combination

• High volume, complex shape → injection molding as the base process.

• Long profiles, rails, tubes → extrusion for the main shape.

• Tight sealing faces and precision fits → finish with CNC machining on critical areas.

• Small batches or prototypes → 3D printing for concept and fit checks, then convert to molding / machining for final parts.

4.4 Know when not to use nylon

If you need zero leakage at high pressure, very hot water, aggressive chemicals or almost no dimensional change at all, it is often smarter to switch to another material (for example POM, PVDF, PEEK or metal) than to force nylon to “pretend” it is fully waterproof.

5. Design Tips for Water-Resistant Nylon Parts

Nylon doesn’t become “waterproof” just because you picked the right grade. Whether a part survives humidity, splashes or pressure really depends on how you design walls, ribs, sealing faces and drainage, and how you allow for moisture-driven growth from dry to wet state. The points below apply to injection-molded, CNC-machined, extruded and 3D-printed nylon parts.

5.1 Wall thickness and rib design

Keep wall thickness as uniform as possible

• Reduces local sink, internal stress and warpage that can open up sealing surfaces over time.

Avoid very thick pads under bosses or inserts

• Step down thickness in two or three levels instead of one big jump.

Place ribs away from critical sealing areas

• Ribs that end under a gasket or O-ring land often cause local distortion.

For long extruded profiles

• Balance wall thickness around the section so the part doesn’t twist or bow when it absorbs moisture.

5.2 Geometry of sealing and mating surfaces

O-ring grooves

• Follow standard groove widths and depths for the chosen O-ring size and hardness.

• Use smooth transitions and generous lead-in chamfers to avoid cutting the seal.

Flat gasket faces

• Provide enough land width for proper compression, not just a sharp edge.

• Use controlled fillets (not sharp corners) to reduce stress and keep surfaces flatter.

Surface finish on sealing areas

• Define a target Ra range—smooth enough to avoid leak paths, but not mirror flat.

• For 3D-printed parts, plan secondary machining or grinding on sealing faces whenever water tightness matters.

5.3 Avoiding water traps and adding drainage

Look for pockets and dead corners in housings and profiles

• Deep blind holes, sharp internal corners and closed cavities tend to collect water.

Add drain holes and flow channels

• Provide low-point drain paths so water can escape by gravity instead of sitting against nylon for weeks.

• Use gentle slopes in channels and cavities to guide water towards an exit.

Separate sealing and drainage functions

• Design a primary sealing interface and a secondary drain path behind it, so any small leak does not turn into long-term immersion.

5.4 Designing for “dry to wet” dimensional change

Drawings should reflect in-service conditions, not just dry parts on the bench

• For tight fits and sealing dimensions, think in terms of size after the nylon has absorbed moisture.

Adjust tolerances for moisture growth

• Leave room in the tolerance stack so swelling does not overload seals, crush gaskets or lock moving parts.

Consider post-conditioning and finish machining

• For critical interfaces, condition parts to a defined humidity level first, then do final machining or grinding on sealing faces.

• For extruded profiles, let them stabilize before cutting final lengths and machining key features.

6. Processing and Post-Treatment: How They Impact Water Performance

Material choice and design are only half the story. The way you dry, mold, machine, extrude and print nylon can easily make the difference between “works fine in wet conditions” and “mysterious leaks everywhere”.

6.1 Injection molding: drying, molding conditions and conditioning

Proper pre-drying

• Underdried pellets can create bubbles, voids and silver streaks that act as capillaries for water.

Mold temperature and packing/holding

• Too cold or too low pack pressure leaves the part less dense and more prone to micro-porosity and warpage, both of which hurt sealing.

Post-molding conditioning

• Let parts reach a controlled moisture level before final inspection and assembly, so dimensional growth happens in your factory, not in the field.

6.2 CNC machining: process control around sealing areas

Coolant and moisture pick-up

• Prefer non-water or low-water coolants on critical parts to avoid accelerating moisture absorption during machining.

Stock allowance and tool paths

• Leave enough finish stock on sealing faces and critical fits so you can clean up any distortion or residual stress.

• Plan tool exits, relief grooves and retracts so you do not accidentally cut “leak channels” across sealing lands.

6.3 Extrusion: stability along the line

Temperature, puller speed and cooling

• Poor control leads to uneven wall thickness, ovality and internal stress, which show up later as distortion when the profile absorbs water.

Post-extrusion straightening and sizing

• Allow profiles to cool and relax, then straighten, calibrate and cut to length before adding any precision features or sealing surfaces.

6.4 3D printing: porosity and moisture at every step

Drying powder or filament

• Wet nylon feedstock produces porous, weak parts that soak up water even faster.

Print settings and infill

• Layer height, wall count and infill pattern all influence how many internal paths water can use.

Post-processing for wet service

• For parts exposed to water or high humidity, plan extra steps such as heat-drying, infiltration, coating or light finish machining on critical sealing areas.

7. Coatings and Hybrid Solutions When Nylon Alone Isn’t Enough

Sometimes even the best nylon grade and design can’t hit the water performance you need. In those cases, you can either upgrade the surface, build a hybrid structure, or change material entirely.

7.1 Hydrophobic and barrier coatings on solid nylon parts

Typical coating types

• PU coatings: flexible, good for housings, covers and non-critical wetted surfaces.

• Silicone coatings: very hydrophobic, good release and anti-stick behavior on valves, guides and exposed surfaces.

• Fluoropolymer coatings (e.g. PTFE-based): strong chemical resistance and low surface energy, good for wetted flow paths and fittings.

• Epoxy and other barrier paints: useful as a tougher outer layer on housings and brackets in splash zones.

Where they make sense

• External surfaces of housings, caps and covers exposed to rain, wash-down or splash.

• Flow passages where you need lower water absorption in the wall and smoother flow.

• Metal-plated or coated sealing lands to reduce swelling and improve wear.

7.2 Nylon plus soft sealing materials

Hard nylon, soft seal

• Use nylon for structure and stiffness, and let rubber, TPE or TPU handle the actual sealing.

Overmolding

• Overmold a soft seal directly onto a nylon housing, flange or connector body so the sealing geometry is fixed and repeatable.

Separate seals

• Design grooves and pockets for separate O-rings, flat gaskets or custom TPE profiles that can be replaced if they wear out or age.

This approach accepts that nylon will move with moisture and temperature, and uses the soft material to follow that movement while maintaining a tight seal.

7.3 When to change material instead of forcing nylon to be “waterproof”

There are limits to how far coatings and seals can go. It is usually safer to move away from nylon when you have:

- Continuous hot water or steam exposure over long periods

- Strong chemicals, cleaners or solvents attacking the polymer

- Very strict IP68-type requirements with long-term immersion under pressure

- Almost zero tolerance for dimensional drift in critical sealing or alignment features

In these cases, materials like POM, PVDF, PEEK or metals often give a more robust solution than trying to make nylon behave like a fully waterproof barrier.

8. Testing the Water Resistance of Nylon Parts

You can’t judge nylon’s water performance by material data sheets alone. You need simple, repeatable tests that match how the part will actually be used.

8.1 Lab standards in simple terms

Water absorption: ASTM D570 / ISO 62

• Measure weight gain after soaking standard specimens in water for a defined time and temperature.

• Tells you how “wet” the material can get and how fast it absorbs moisture.

Ingress protection (IP) levels

• IP ratings (e.g. IP54, IP67, IP68) describe how complete assemblies resist dust and water, not just materials.

• Tests use spray, splash or immersion under defined conditions to check for water inside the enclosure.

These standards give you baseline numbers, but custom parts usually need more targeted checks.

8.2 Practical “engineering” test methods for custom nylon parts

Static immersion + dimensional check

• Soak parts in water or a relevant fluid for a set time (24–168 hours) at a realistic temperature.

• Measure critical dimensions before and after to see swelling and distortion.

Pressurized water or spray leak tests

• For housings, valves and connectors, apply internal pressure or external spray while monitoring for leaks.

• Use colored water or low-viscosity test fluid to make leak paths visible.

Temperature and humidity cycling

• Cycle parts between hot/cold and dry/humid conditions while assembled.

• Inspect for cracks, warpage, seal extrusion and loss of clamping force over multiple cycles.

8.3 Using test results to improve design and process

If you see leaks

• Map leak paths back to specific features: sharp corners, thin lands, weld lines, surface steps.

• Adjust sealing geometry, surface finish, rib placement or molding conditions in those areas.

If you see excessive dimensional drift

• Consider switching to a lower-absorption nylon grade (e.g. PA12/PA610) or adding glass reinforcement.

• Revisit tolerances, add post-conditioning before assembly, or change the sequence of molding, machining and inspection.

If failures are random or inconsistent

• Look first at process variation: drying, molding parameters, cooling, machining setup and print/extrusion stability, not just the drawing.

9. Case Study: Nylon Parts in Wet Conditions

Case 1 – Injection-molded nylon pump housing: from leaks to passing pressure tests

Problem

• A nylon pump housing passed initial leak tests, but after several weeks of endurance testing it started to seep at the joint between the main body and cover.

Actions

• Reworked gate and rib layout to reduce weld lines and local warpage in the sealing area.

• Added a dedicated O-ring groove with controlled land width and chamfers instead of relying on “flat-to-flat” contact.

• Tightened drying control for the pellets and increased mold temperature / packing pressure to get a denser molding.

Result

• The updated design consistently passed internal pressure tests at the specified pressure and hold time, with no visible seepage across multiple batches.

Case 2 – CNC-machined nylon valve block: humidity-driven drift fixed

Problem

• A machined nylon valve block assembled perfectly in the factory, but after a few weeks in a high-humidity environment some units developed small leaks around threaded ports and sealing faces.

Actions

• Switched from a standard PA6 grade to a lower-absorption nylon grade to reduce dimensional growth.

• Introduced a conditioning step so blocks reached moisture equilibrium before finish machining of all sealing faces and critical bores.

• Relaxed some press fits and adjusted gasket compression to allow for small, predictable swelling without overloading seals.

Result

• After the change, field units stayed dimensionally stable enough in service and leak complaints dropped to zero over the next inspection cycles.

Case 3 – Extruded nylon guide profile: solving condensation and jamming

Problem

• An extruded nylon guide profile used in a cold area accumulated condensation water in hidden pockets, leading to corrosion on nearby metal hardware and occasional jamming of moving parts.

Actions

• Modified the profile cross-section to add low-point drain channels and a slight slope in the bottom geometry so water naturally flowed out.

• Smoothed internal corners and removed unnecessary pockets where droplets could sit.

Result

• After retrofit, water no longer accumulated inside the profile, corrosion marks disappeared in later inspections, and the guiding system ran without jamming under the same operating conditions.

10. Decision Checklist for Designers and Buyers – and How We Can Help

By this point, the question is no longer “is nylon waterproof?” but “is nylon good enough for your wet environment if we choose and process it correctly?”. A few simple checks help you decide:

Nylon is not an absolute barrier to water

• It absorbs moisture and changes size, but with the right grade, design and process it can be reliable in many wet and humid applications.

Start from the real environment, not the material name

• What fluid, what temperature, how long, how often, and at what pressure will the part see water or high humidity?

Be honest about what you can tolerate

• How much dimensional growth is acceptable after conditioning?

• How much leak risk is acceptable at joints, threads and seals?

Choose grade + process as a package

• PA6/PA66 for general humid service, PA12/PA610 and glass-filled variants when you need lower swelling and better stability.

• Injection molding or extrusion for the base shape, CNC machining for critical sealing faces, 3D printing mainly for prototypes or parts that will be sealed or coated later.

Use tests to close the loop

• Simple soak, leak and cycling tests on real parts will tell you if the design and process are good enough long before field failures do.

If you are working on nylon parts for wet or humid conditions and are not sure which grade, process route or test plan to use, you can share your drawings and operating conditions with us. We can help you pick a suitable nylon grade, decide between machining, injection molding or extrusion, and suggest practical test methods to check water resistance before you commit to full production.

For CNC-machined nylon components, you can refer to our CNC Machining page.

If you need complete injection molded assemblies, see our Plastic Parts page.

And if you are still comparing resin options, our Plastics Materials overview may help you shortlist the right grades.