1. Introduction — Why There Is No Single Price for a Metal Part

If you search how much to get a metal part made, you will quickly notice there is no clear or universal answer. That is not because suppliers are avoiding transparency, but because metal part pricing does not work like retail pricing.

There are three realities you need to understand first:

● There is no fixed price

A metal part is not priced per piece or per kilogram in a standard way. Two parts with the same weight can cost 5× or 10× different depending on how they are made.

● Different manufacturing processes follow completely different cost models

CNC machining, sheet metal fabrication, casting, and metal injection molding all have unique cost drivers. Setup time, tooling, cycle time, and volume affect each process in very different ways.

● Cost depends on choosing the right process and the right production location

The cheapest option is rarely about “lowest hourly rate.” It is about matching your design, quantity, and timeline with the right manufacturing method—and knowing when a local metal shop makes sense versus a specialized supplier.

This guide breaks down how metal part costs are actually formed, compares major manufacturing processes, and explains how to choose the right process and sourcing strategy before you request a quote.

2. What Really Determines the Cost of a Metal Part

The cost of a metal part is not random. It is the result of a small number of technical variables that compound together. Understanding these variables is the fastest way to predict pricing accuracy—and to avoid unnecessary cost before quoting.⸻

2.1 Material Selection and Availability

Material choice affects cost in three ways:

● Raw material price

Aluminum, carbon steel, stainless steel, and specialty alloys differ significantly in base cost.

● Machinability and processing difficulty

Some materials cut quickly and predictably; others increase tool wear, cycle time, and scrap risk.

● Supply stability

Readily available materials reduce lead time and price volatility, while specialty or certified materials often add cost and delay.

Material is rarely the largest cost driver by itself, but it directly impacts every step that follows.

2.2 Design Complexity and Machining Time

Design complexity translates almost directly into machine time.

Key contributors include:

● Number of machining operations

● Multi-axis vs. simple 2.5D features

● Internal pockets, deep cavities, thin walls

● Required fixturing or part repositioning

More complexity means longer cycle times, more setups, and higher labor and machine costs—regardless of part size or weight.

2.3 Tolerances, Surface Finish, and Inspection

Precision always has a price.

● Tighter tolerances require slower cutting speeds, more passes, and often secondary finishing.

● Surface finish requirements can add polishing, grinding, or coating steps.

● Inspection level increases cost through CMM checks, documentation, and quality control labor.

A common cost mistake is specifying tight tolerances everywhere when only a few features actually require them.

2.4 Quantity, Tooling, and Setup Cost

Quantity determines how costs are distributed.

● Setup and programming costs are mostly fixed.

● Unit cost decreases as those fixed costs are spread across more parts.

● Tooling investment may be minimal for machining but significant for other processes.

This is why a single prototype can cost more per piece than a small production run—even with identical geometry.

2.5 Post-Processing and Assembly

Many parts are not finished when they leave the machine.

Additional cost may come from:

● Heat treatment for strength or stability

● Surface coatings or plating

● Welding or mechanical assembly

● Final inspection or functional testing

Each secondary operation adds handling, coordination, and quality risk—and should be considered part of the total cost, not an afterthought.

Together, these factors form the true cost structure of a metal part.

3. Cost Ranges by Manufacturing Process

This is the point where cost estimation becomes concrete.

Once you choose a manufacturing process, the pricing model changes completely.

Different processes are not variations of the same cost curve—they are different curves altogether.

3.1 CNC Machining Cost (Prototype to Low Volume)

CNC machining is the most flexible option and the most common starting point.

Typical use cases

● One-off prototypes

● Low-volume production

● Design iterations and engineering changes

Cost characteristics

● Minimal or no tooling cost

● Pricing driven mainly by machine time and setups

● Fast lead times compared to other processes

CNC machining scales poorly with volume, but it excels at speed, accuracy, and design freedom—making it the baseline reference for later process comparisons.

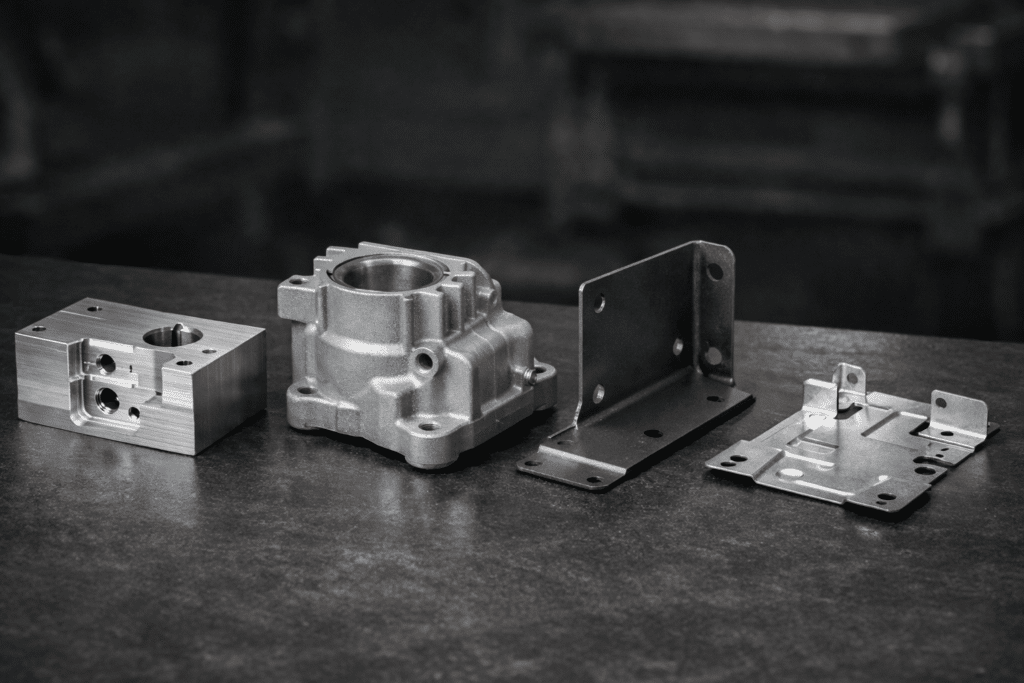

3.2 Casting and Fabrication Cost Overview

Casting and fabrication processes are widely used for medium to high-volume production, not because they outperform machining in mechanical strength, but because they achieve lower unit cost through tooling, repeatability, and production efficiency.

Machined parts typically offer more consistent and superior mechanical properties, while casting and forming trade some material performance for scalability and cost control.

Sand casting

● Lower tooling cost

● Suitable for low to medium volumes

● Thicker walls and less geometric detail

● Machining often required for critical features

Die casting

● High upfront die cost

● Very low unit cost at high volume

● Excellent repeatability

● Common for aluminum and zinc components

Metal stamping

● Tooling cost can be high

● Extremely low unit cost at volume

● Ideal for flat or formed sheet metal parts

● One of the most cost-effective processes for large quantities

Sheet metal fabrication

● Flexible compared to stamping

● Cost driven by cutting, bending, welding, and assembly

● Scales well for low to medium volumes

These processes reduce unit cost at scale but introduce trade-offs in tooling investment, design flexibility, and lead time.

3.3 Metal Injection Molding Cost

Metal injection molding follows a fundamentally different cost logic.

Key cost characteristics

● Very high initial mold cost

● Extremely low unit cost once production begins

● Minimal secondary machining for complex small parts

Best suited for

● Complex geometries that are difficult or expensive to machine

● Production volumes from several thousand to hundreds of thousands

● Small, high-precision components

Why it is not a CNC replacement

CNC machining optimizes for flexibility and speed.

Metal injection molding optimizes for repeatability and scale.

Once tooling is committed, design changes become expensive, but unit cost drops dramatically. This places metal injection molding in a different category—not better or worse, but optimized for a different production reality.

Key takeaway:

For prototypes and low-volume production where design flexibility and fast iteration matter, CNC machining for prototype and low-volume parts is often the most practical manufacturing option.

For high-volume production with complex geometry, the die casting manufacturing process offers excellent repeatability and low unit cost once tooling is in place.

For flat or formed sheet metal components produced at scale, metal stamping for high-volume production is often one of the most cost-efficient manufacturing options.

When parts require cutting, bending, welding, or assembly flexibility, custom sheet metal fabrication provides a practical balance between cost, speed, and design adaptability.

4. Mold Injected Metal vs Machined or Cast: Cost, Volume, and Design Trade-offs

Choosing between mold injected metal, machining, or casting is not about which process is “better.”

It is about matching cost structure, volume, and design intent to the right manufacturing method.

The table below highlights the key differences that drive real-world decisions.

| Process Comparison | |||

| Factor | Machined Metal | Cast Metal | Mold Injected Metal |

| Upfront Cost | Low | Medium to high | Very high |

| Unit Cost | High | Medium | Very low |

| Best Volume Range | 1–1,000+ | 500–100,000+ | 5,000–500,000+ |

| Design Complexity | High, flexible | Moderate | Very high for small parts |

| Mechanical Properties | Excellent, predictable | Good, process-dependent | Moderate, density-dependent |

| Dimensional Accuracy | High | Medium | High |

| Tooling Dependency | Minimal | High | Very high |

Cost Structure Comparison

● Machining concentrates cost in machine time and labor. There is little upfront investment, but unit cost remains relatively high as volume increases.

● Casting shifts cost toward tooling and dies, reducing unit cost at scale but increasing commitment.

● Mold injected metal requires the highest initial investment, with tooling dominating early cost and unit price dropping sharply only at large volumes.

Volume Breakpoints

Each process has a clear economic crossover point:

● Machining is most efficient for prototypes and low volumes.

● Casting becomes cost-effective once tooling is amortized across consistent production runs.

● Mold injected metal only makes sense when volume is high enough to absorb tooling cost and maximize per-part savings.

Selecting a process without understanding this breakpoint often leads to severe cost overruns.

Design Freedom and Constraints

● Machining offers the highest design flexibility and easiest iteration.

● Casting allows complex external shapes but introduces draft angles, wall thickness limits, and porosity considerations.

● Mold injected metal enables very complex small geometries but locks design tightly to the mold.

Once tooling is built, design freedom decreases sharply.

Cost of Design Changes

● Machined parts allow low-cost and fast design changes.

● Cast parts require tooling modification, often expensive and time-consuming.

● Mold injected metal changes can mean partial or full mold replacement, making late-stage revisions extremely costly.

Early design validation is critical when tooling-heavy processes are selected.

Lead Time and Risk

● Machining offers the shortest and most predictable lead time.

● Casting adds lead time for tooling and sampling.

● Mold injected metal carries the highest schedule risk due to tooling complexity, sintering behavior, and first-article validation.

The more tooling-dependent the process, the higher the risk of delay.

Key takeaway:

Machining optimizes for flexibility and performance, casting balances cost and volume, and mold injected metal optimizes for scale and repeatability. The right choice depends on when cost savings outweigh loss of flexibility and increased commitment.

5. How Location Impacts Cost: Local vs Overseas Manufacturing

Manufacturing location affects cost in ways that are often misunderstood.

“Local” does not automatically mean cheaper, and “overseas” does not automatically mean slower or lower quality.

What location really changes is communication speed, iteration cost, and production flexibility.

5.1 Is “Metal Fabrication Near Me” Always Cheaper?

Searching for metal fabrication near me is usually driven by urgency, not price.

Where local fabrication helps

● Faster communication and face-to-face discussions

● Rapid prototyping and same-day adjustments

● Easier coordination for design clarification

Where it does not

● Unit price is often higher due to labor and overhead

● Limited equipment compared to specialized facilities

● Less cost efficiency at scale

Local fabrication is about speed and convenience—not guaranteed cost savings.

5.2 Working with Metal Fabricators Near Me vs Global Suppliers

The term metal fabricators near me reflects a commercial comparison mindset.

Local fabricators

● Easier sampling and short feedback loops

● Smaller batch flexibility

● Limited capacity for large or complex programs

Global suppliers

● Lower unit cost at medium to high volume

● Access to specialized processes and automation

● Longer communication cycles, but higher scalability

For cost-sensitive or volume-driven projects, comparing multiple suppliers across regions often reveals significant differences in total landed cost.

5.3 When a Metal Workshop Near Me Makes Sense

A metal workshop near me is best suited for specific scenarios.

Typical use cases

● Simple welding or bracket fabrication

● Repair or replacement of existing parts

● Non-standard, one-off, or low-repeat jobs

These workshops excel at solving immediate, practical problems—but they are not designed for optimized cost, tight tolerances, or scalable production.

Bottom line:

Local manufacturing optimizes for speed and access. Overseas manufacturing optimizes for scale and cost efficiency. The right choice depends on whether responsiveness or unit economics matters more at your current stage.

6. A Simple Way to Estimate Your Metal Part Cost

Before requesting quotes, you should have a rough internal cost expectation.

You do not need an exact number—you need a reasonable range to evaluate whether a quote makes sense.

Instead of guessing or calculating formulas manually, you can estimate metal part cost by entering a few key inputs and letting the system generate a realistic range instantly.

Metal Part Cost Estimator

Die Casting

If you are evaluating die casting economics, a dedicated estimator provides better accuracy.

You can use this Precision Die Casting Cost Estimator to model tooling cost, unit price, and volume impact more realistically.

Why this matters:

Suppliers quote differently, but cost structures are consistent.

If you understand the structure, you can quickly spot unrealistic pricing and choose the right manufacturing path before committing.

7. How to Reduce Cost Before You Request a Quote

The biggest cost savings do not come from negotiating after you receive a quote.

They come from design and process decisions made before you ever contact a supplier.

Optimize Cost at the Design Stage

Design decisions lock in cost earlier than most buyers realize.

● Avoid over-engineering features that do not affect function

● Use standard thicknesses, hole sizes, and radii where possible

● Limit tight tolerances to critical features only

● Design parts to be fixtured and produced in as few setups as possible

Small design adjustments at this stage can reduce manufacturing cost far more than any later price discussion.

Choose the Right Manufacturing Process Early

Selecting the wrong process is the largest and most common source of cost waste.

● Machining is ideal for flexibility, not volume efficiency

● Tooling-based processes require commitment but reward scale

● Changing processes late often means redesign, re-tooling, or both

A part that is technically manufacturable by multiple processes is rarely cost-efficient in all of them.

Design with Volume in Mind

Cost targets should align with expected production quantity.

● Prototypes should prioritize speed and changeability

● Production parts should prioritize repeatability and unit cost

● Mixing prototype design logic with production volume expectations almost always inflates cost

Clarifying volume early prevents expensive redesigns later.

Share Manufacturing Intent Clearly

Suppliers price risk into quotes when intent is unclear.

● Communicate expected volumes, future scaling plans, and tolerance priorities

● Clarify which features are functional versus cosmetic

● Indicate where flexibility is acceptable

Clear intent reduces contingency pricing and leads to more accurate quotes.

Key takeaway:

Cost reduction starts before quoting.

The right design and the right process choice matter more than price negotiation ever will.

8. FAQ

1) How much to get a metal part made for a prototype?

Prototype cost varies widely, but it is usually driven by setup time, programming, and part complexity rather than material weight. For one-off or low-quantity parts, CNC machining is commonly used because it avoids tooling cost and allows fast iteration.

2) Is metal injection molding cheaper than CNC machining?

It depends on volume. Metal injection molding has very high upfront tooling cost but very low unit cost at scale. CNC machining has low startup cost but higher unit cost. For prototypes and low volumes, machining is typically cheaper. For large, stable production runs, metal injection molding can become more economical.

3) Should I choose a metal fabrication shop near me?

A local metal fabrication shop can be a good choice for quick turnaround, prototyping, or simple fabrication work. However, local availability does not always mean lower unit cost. For larger volumes or specialized processes, comparing multiple suppliers—including overseas options—often leads to better cost efficiency.

9. Conclusion — Price Is a Result, Not a Starting Point

The cost of a metal part is never just a number. It is the outcome of several decisions made long before a quote is issued.

● Manufacturing process defines the cost curve

Each process follows a different economic model. Choosing the right one matters more than chasing a lower hourly rate.

● Production volume determines the break-even point

Fixed costs, tooling, and setup only make sense when volume supports them. Volume clarity prevents costly misalignment.

● Location affects efficiency, not automatically price

Local suppliers improve speed and communication, while global suppliers often improve unit economics. Neither is universally cheaper.

Understanding these relationships allows you to evaluate quotes intelligently, avoid unnecessary cost, and select the right manufacturing path with confidence.