1. What is Bronze Machining?

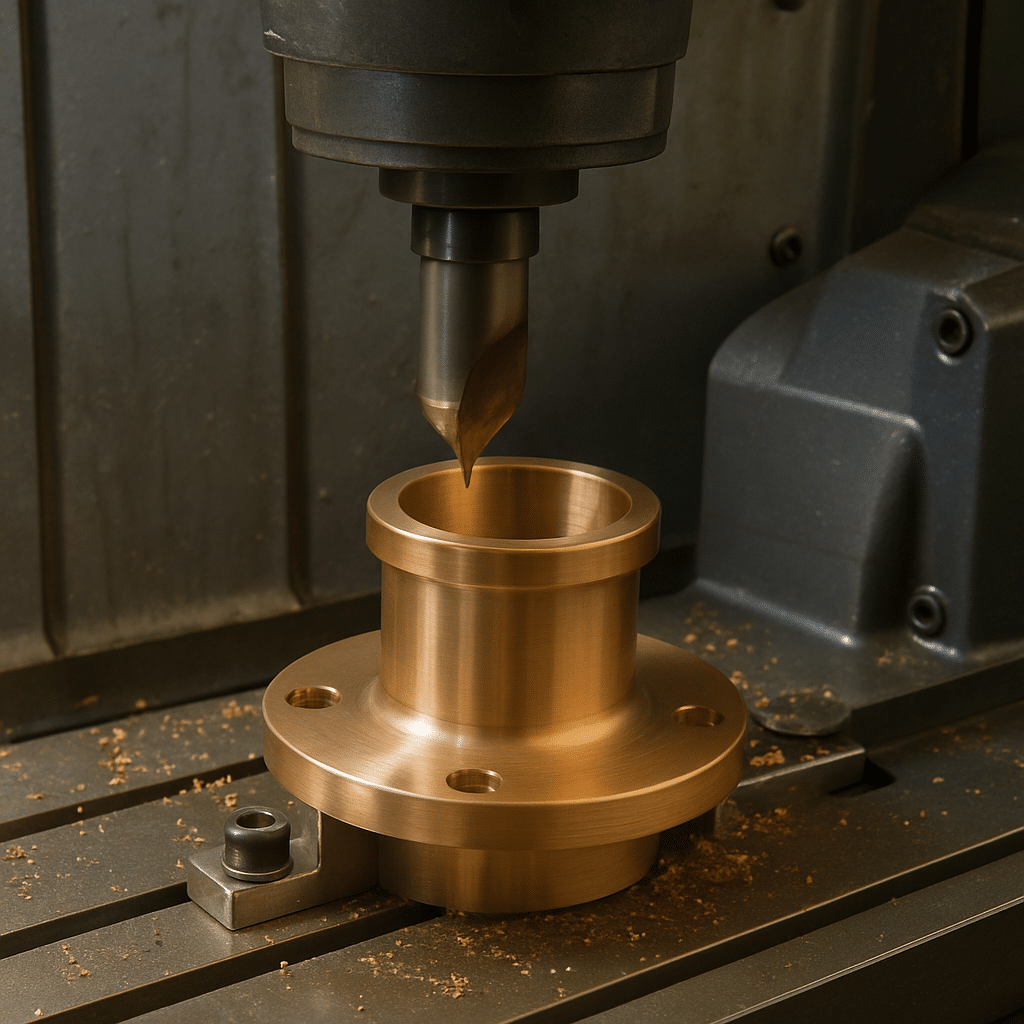

Bronze machining involves cutting, engraving, milling, turning, and grinding to make parts.

Key Features:

● High Hardness

Bronze’s high hardness and strength require suitable tool materials (such as carbide tools) and low machining speeds to prevent excessive tool wear.

● Excellent Cutting Performance

Despite its hardness, bronze is relatively easy to machine, especially tin bronze (such as copper-tin alloys) and aluminum bronze, which exhibit excellent cutting performance.

● Corrosion Resistance

Bronze has strong corrosion resistance and is suitable for environments requiring corrosion and wear resistance, such as ships, chemical equipment, and mechanical parts.

● Process Diversity

Depending on the specific part requirements, bronze can be turned, milled, ground, and drilled to produce parts with complex shapes.

2. Commonly Used Bronze Types and Applications

| Table 1 – Bronze Types and Their Applications | |||||

| Bronze Types | Common Grades | Main Chemical Composition | Features | Processing Performance | Applications |

| Tin Bronze | ● Chinese: QSn6.5-0.1 ● Japanses: C5111/C5191 | Cu: 83-85% Sn: 3-14% P: 0.01-0.5% | High strength, wear resistance, and corrosion resistance | Good (moderate) | Bearings, sliding parts, gears, springs, electrical components |

| Aluminum Bronze | ● Chinese: QA19-2, QA17,QA19-4, QAl10-3-1.5 ● American: C95400, C95500 | Cu: 88-98% Al: 2-12% Fe: 0.5-5% | Extremely high strength, wear resistance, excellent corrosion resistance | Poor (rapid work hardening) | Heavy-duty gears, marine propellers, pump casings, valve bodies |

| Manganese Bronze | ● Chinese: QMn1.5, QMn2, QMn5 ● American: C86300, C67500 | Cu: 80-90% Mn: 5-10% | Impact-resistant, corrosion-resistant, and affordable | Good | Heavy-duty bearings, mining machinery components, and construction materials |

| Phosphor Bronze | ● Chinese: QSn4-3, QSn4-0.3 ● Japanese: C5212, C5210 ● American: C51900, C51000 ● European: CW450K, CW451K | Cu: >88% Sn: 0.5-10% P: 0.01-0.5% | High elasticity, low friction, fatigue resistance | Very good | Precision springs, contact plates, bushings, bearing liners |

| Lead Bronze | ● Chinese: ZCuPb30 ● American: C83600, C93800, C93700, C93600 | Cu:79-85% Pb: 8-30% Sn: 2-10% | Strong self-lubrication and anti-seizure properties | Good | Sliding bearings, bushings, guides |

| Silicon Bronze | ● Chinese: QSi3-1, QSi1-3 ● American: C65500, C65100 | Cu:>90% Si: 0.5-4% Mn: <0.5% Ni: <0.5% | High strength, corrosion resistance, and good weldability | Good | Chemical equipment, springs, fasteners, electrical connectors |

3. Bronze Machining Process

3.1 Material Preparation

Material Selection: Choose the right bronze grade (e.g., tin bronze, aluminum bronze, etc.) based on the product application, drawing requirements, etc.

Blank Preparation: Bronze is typically supplied in ingots, bars, plates, etc., and can be sawn to size before machining. Check whether the blank has defects such as pores and cracks.

Tool Selection

● Carbide tools (such as YG8 and YW2): Suitable for most bronzes and offer excellent wear resistance.

● High-speed steel (HSS) tools: Suitable for low-speed finishing or complex shapes.

● Diamond-coated tools: Suitable for difficult-to-machine materials such as high-silicon and beryllium bronze.

3.2 Pre-Processing

Clamping Preparation: Select appropriate fixtures to avoid pinching soft materials (such as lead bronze).

Alignment/Correction: For lathe and milling machines, the center should be accurately aligned to avoid runout caused by eccentricity.

Preheating (if necessary): For large or complex parts, preheat the material appropriately to reduce internal stress.

3.3 Rough Machining

Process: Rough turning/milling to cut the bronze blank to near-finished dimensions.

Recommended Parameters:

I. Turning

● Tool Angle: Rake angle (8°-12°), relief angle (6°-8°), sharp cutting edge to reduce chipsticking

● Cutting Parameters:

Cutting speed (Vc): 120-180 m/min

Feed Rate (f): 0.1-0.3 mm/rev (lower values for harder grades)

Axial depth of cut (ap): 1-3 mm for roughing, 0.1-0.5 mm for fine finishing

II. Milling

● Tool: 4-6 fluted carbide end mill, helix angle 30°-45° to reduce vibration

● Parameters:

Cutting speed (Vc): 80-150 m/min (speed should be reduced for larger end mill diameters)

Feed per tooth (fz): 0.05-0.15 mm/z (≤0.08 mm/z for finish milling)

Axial depth of cut (ap): 0.5-2 mm (less for fine milling)

III. Drilling

Drill speed: For a Φ5 mm drill, 800-1200 rpm is recommended

Feed rate(f): 0.05-0.1 mm/rev

Drill point angle: 118°-135°, with the back angle ground to 8°-10° to extend tool life

Chip removal should be performed in stages when drilling deep holes

IV. Grinding

Grinding Wheel: Green silicon carbide (GC) or diamond wheel, grit 60-120

Parameters:

Linear Speed: 20-30 m/s

3.4 Fine Finishing

Process: Fine turning, milling, grinding, drilling, etc to meet dimensional tolerances and surface requirements.

3.5 Deburring & Surface Treatment

Deburring: Use a nylon brush, vibratory polisher, or hand scraper to remove sharp edges.

Surface Treatment:

Grinding or polishing is available if a high finish is required.

Boring or lapping can improve dimensional consistency and internal hole quality.

Some parts need to be plated with nickel or chromium to enhance corrosion resistance.

3.6 Post-Processing (As Needed)

Heat Treatment (Optional): Some aluminum-bronze parts may undergo aging treatment to increase strength.

Assembly Inspection: Dimensional re-inspection and assembly fit confirmation are performed.

3.7 Quality Inspection

Check product sizes and functions according to drawing & customer’s requirement.

4. Surface Finishes for Bronze Machined Parts

4.1 Common Surface Finishes for Bronze Machined Parts

| Table 2 – Common Surface Finishes for Bronze Machined Parts | |||

| Surface Finishes | Functions & Features | Applications | Notes |

| Sandblasting | Deburrs, removes mill scale, and creates a uniform matte surface | Pre-treatment for painting and electroplating to improve adhesion | Avoid excessive sandblasting to avoid damaging the substrate |

| Polishing/Mirror Finishing | Improves surface finish and aesthetics | Decorative items, instrument parts, and artwork | Use with caution for components requiring high geometric accuracy |

| Phosphating | Enhances rust resistance and improves coating adhesion | Industrial machinery parts, military components | Bronze is less commonly used than steel, so a dedicated phosphating solution is used |

| Electroplating (Nickel/Chromium/Gold) | Enhances corrosion resistance, aesthetics, and conductivity | Electronic components, precision parts | Thoroughly clean the bronze surface to prevent peeling |

| Chemical Coloring (Black/Bronze) | Provides decorative hues and anti-oxidation protection | Artistic copper pieces, antique hardware, signage | Requires controlled oxidant concentration and duration |

| Painting/Epoxy Coating | Aesthetics, corrosion protection, and identification | Industrial structural components, equipment housings | Surface pretreatment is required to ensure secure adhesion |

4.2 Common Problems and Recommendations for Bronze Surface Finishes

| Table 3 – Common Problems and Recommendations for Bronze Surface Finishes | ||

| Problems | Possible Causes | Recommendations |

| Surface treatment layer easily peels | Incomplete substrate cleaning, residual oil | Strengthen pre-treatment for degreasing and rust removal |

| Uneven coloring | Inconsistent surface roughness | Pre-treatment to uniform roughness (sandblasting/pickling) |

| Blistering from electroplating | Surface inclusions and pores | Using an intermediate layer (such as copper plating) as a primer before electroplating |

| Discoloration after polishing | Oxidation due to exposure to humid air | Immediately seal with wax or spray with anti-oxidation oil after polishing |

5. Common Challenges in Bronze Machining and How to Overcome Them

5.1 Common Challenges in Bronze Machining and Measures

| Table 4 – Common Challenges in Bronze Machining and Measures | |||

| Problems | Descriptions | Main Cause | Measures |

| Rapid tool wear | Blunt cutting edge, shortened machining time | ● High-hardness bronzes such as aluminum bronze and beryllium bronze can accelerate tool wear ● Excessively high cutting temperatures can cause thermal softening and oxidation on the tool surface, reducing tool hardness and potentially causing tool damage | ● Use carbide or coated cutting tools ● Enhance cooling to avoid dry cutting ● Reduce high-speed idling |

| Work hardening | Difficult subsequent processing, unable to cut, severe heating | Aluminum bronze and beryllium bronze are prone to plastic deformation during processing, which can lead to an increase in surface hardness | ● Complete the cut in one go, avoiding repeated cuts ● Increase the feed rate to avoid light cuts and scratches ● Use cutting fluid to reduce cutting temperature |

| Rough surfaces | Part surfaces are not smooth, even scratched | ● Weak tool ● Improper cutting speed ● Chips sticking to the tool tip | ● Ensure tool sharpness and replace regularly ● Reduce feed rate and depth of cut ● Vibration polishing or electrolytic polishing after machining to improve surface quality |

| Chip sticking to the tool | Copper chips stick to the cutting edge, affecting size and surface finish | ● Bronze (especially tin bronze and lead bronze) is soft and its chips easily adheres to the cutting tool’s rake face during cutting, forming built-up edge (BUE) ● Excessive cutting temperature causes the material to soften | ● Use carbide tools with sharp cutting edges (such as YG8 and YW2) ● Use PVD-coated tools (such as TiAlN coating) to reduce friction and sticking ● Increase the tool rake angle (10°-15°) to reduce cutting resistance ● Enhance cooling and lubrication |

| Difficult chip removal | Chips wrap around the tool or workpiece, affecting cutting | Bronze chips are typically long, ribbon-like and easily entangled with the tool or workpiece | ● Adjust tool geometry to facilitate chip breaking ● Use a chipbreaker tool or chip removal device ● Install a gas blower or high-pressure cutting fluid system |

| Machining deformation (dimensional instability) | Oversized or undersized after machining | ● Bronze is soft, and excessive clamping force or uneven cutting force can cause deformation ● Residual stress release leads to subsequent deformation | ● Use a soft-jaw chuck or hydraulic clamp to avoid over-clamping ● Add support points and reduce overhang length ● After rough machining, perform stress relief annealing (250-300°C) before fine finishing ● Use a small depth of cut and multiple passes to reduce cutting forces |

| Poor hole machining accuracy | Hole diameter is too large, rough, or eccentric | Bronze is highly flexible, and the hole wall is prone to vibration or rebound | ● Use a center drill for pre-positioning ● Use boring rather than drilling whenever possible ● Increase spindle rigidity and reduce vibration |

| Broken/chipped edges | Especially in thin-walled or sharp-angled areas | Insufficient bronze toughness or stress concentration | ● Optimize part design and chamfering ● Use small feed and sharp tools during processing ● Reserve machining allowance in corners and then fine finish |

5.2 Additional Tips for Processing Stability

● Use stable fixtures to prevent vibration and displacement during machining.

● Maintain tool sharpness and change tools frequently, especially for small-diameter drills and reamers.

● Machining paths avoid repeated cutting of the hardened layer; a single pass is more efficient than multiple light cuts.

● Fine finish after 24 hours of rough machining to allow for stress release and stable machining.

6. CNC Machine Shops Near Me – How to Outsource Bronze Machining

If a German buyer wants to find CNC machine shops near him and outsource bronze machining, how do you do it? Below is a detailed step-by-step guide on bronze machining outsourcing.

6.1 Clarify Technical Requirements

Before searching for a supplier, you need to identify the following key information:

● Part requirements: Drawings, tolerances (e.g., DIN ISO 2768-mK), surface roughness (e.g., Ra 1.6μm).

● Material standard: Bronze grade (e.g., European grade CW450K).

● Process requirements: Turning/milling/grinding, and whether post-processing (e.g., polishing, plating) is required.

● Certification requirements: ISO 9001, ISO 14001, or industry-specific certification (e.g., IATF 16949 for the automotive industry).

6.2 CNC Machine Shops Near Me – Four Practical Ways to Find a Nearby Machine Shop

6.2.1 Google Local Search (Accurate + Fast)

Search keyword structure:

CNC Lohnfertigung Bronze + city name

CNC Bearbeitung Kupferlegierungen + city name

CNC Drehteile Hersteller + city name

Tips: It is recommended to open the Google Maps view, directly locate the processing plant, and check its website, ratings, and customer reviews.

6.2.2 German Industrial Platform

● Focusing on the DACH-Region, it primarily provides machinery and industrial products, available in English and German.

● Search: “CNC Bronze Bearbeitung”, choose “Location”, “Supplier type”, “Employees”etc.

● View supplier homepages, websites, certifications, and send inquiries.

● Europages covers multiple industries across Europe and offers multiple language options, facilitating business communication across different countries.

● Search: “CNC Bronze Bearbeitung” , choose “Location”“Supplier type”“Employees” etc.

● View supplier homepages, website, certification, and send inquiries.

● B2B platform for custom non-standard parts.

● Register for free and upload thedrawings, the platform will match withmanufacturers.

● Useful for high-precision requirements; includes a quote system.

● Xometry Europe offers CNC machining, 3D printing, sheet metal fabrication, and injection molding online.

● Upload drawings onlineto get quotation: an automatic quote by 3D drawings, a manual quote by 2D drawings; and local German fabricators will accept orders.

6.2.3 On-site Industrial Park Search (for High-End Buyers)

Almost every German city has an Industriegebiet (industrial park) or Gewerbegebiet (commercial manufacturing area). Buyers can:

- Search the area on Google Maps + “CNC” or “Metallbearbeitung.”

- Or, call the local IHK (Chamber of Industry and Commerce) directly for a list of companies.

6.2.4 Contact Local Industry Associations/Chambers of Commerce

1) IHK (Industrie- und Handelskammer)

- City Chamber of Commerce can be found in every city. It provides company recommendations and procurement support

- VDW(Verein deutscher Werkzeugmaschinenfabriken)

- The German Machine Tool Builders’ Association, provides a directory of local machine tool manufacturers

6.3 RFQ

Send a RFQ email to potential suppliers, see example below:

wir suchen einen Partner für die CNC-Dreh- und Fräsbearbeitung von Bronze.

– Menge: 500 Stück/Jahr

– Zeichnungen und 3D-Daten (STEP/PDF) stehen zur Verfügung

– Toleranz: ±0,05 mm

– Oberfläche: Ra ≤1,6 μm

Bitte senden Sie uns:

1. Ihr Angebot inkl. Bearbeitungszeit

2. Referenzen ähnlicher Projekte

3. Zertifikate (ISO 9001, etc.)

Mit freundlichen Grüßen,

[Ihr Name]

6.4 Supplier Evaluation

| Table 5 – Supplier Evaluation | |

| Items | Focus |

| Material Experience | If suppliers have experience in machining bronze with specific grade |

| Surface Finishes | If suppliers can do surface finishes like plating, painting ect |

| Certification and Compliance | ISO 9001, ISO13485, REACH regulations etc (if necessary) |

| Local Services | Whether design for manufacturing (DFM) and rapid prototype delivery are available |

| Logistics and Inventory | JIT (just-in-time) delivery availability |

Tips:

| Table 6 – Tips to Improve Efficiency | |

| Recommendations | Descriptions |

| Provide STEP/PDF drawings, including requirements like material, surface finish, color, etc | To quick check the feasibility of manufacturing |

| Contact 3-5 local manufacturers first to compare responses | A quote or response will usually be provided within 1-2 days |

| Check whether samples, on-demand purchasing, and small-batch are available | It is safer to place a trial order before entering into a long term partnership |

Read the article below to find more details:

“What is Supplier Quality?” Section 8: Example of Making a Supplier/Vendor Selection

7. Conclusions

Bronze machining involves CNC turning, milling, and drilling various bronze materials (such as tin bronze and aluminum bronze) to create precision parts. While bronze offers excellent machinability, corrosion resistance, and self-lubricating properties, some grades can suffer from work hardening and chip sticking. Therefore, right tooling, cutting parameters, and cooling methods are crucial to ensure dimensional accuracy and surface quality.

8. People Also Ask

1) Property Difference between Bronze and Brass

| Table 7 – Property Difference between Bronze and Brass | ||

| Items | Machining Bronze | Machining Brass |

| Hardness | Typically harder than brass, more difficult to cut | Typically softer, better machinability |

| Strength & Wear Resistance | High strength, excellent wear and corrosion resistance | Relatively poor, but some high-zinc brasses also have good strength |

| Machinability | Relatively difficult to machine, prone to tool sticking and hardening | Excellent machinability, a common material in CNC machining |

| Applications | Valves, sliding bearings, bushings, marine parts, etc. | Decorative parts, plumbing fittings, electrical accessories, etc. |

| Electrical & Thermal Conductivity | Slightly lower than brass | Excellent electrical and thermal conductivity |

2) Machining Differences between Bronze and Brass

Similarities:

● Both can be machined using conventional CNC lathes, milling machines, and drilling machines.

● Both are copper alloys with a certain degree of ductility and machinability.

● Both require sharp tools and appropriate cutting fluids to optimize surface quality.

Differences:

● Bronze is harder and has poorer machinability: especially aluminum bronze and phosphor bronzewear quickly;

● Susceptible to work hardening: Bronze machining results in localized temperature increases, hardening the surface;

● Susceptible to chipsticking: Leaded bronze, in particular, requires enhanced cooling and chip breaking;

● Brass is extremely easy to machine, even with standard machine tools, making it suitable for high-volume, rapid machining.

3) Conclusions

Bronze is harder and more corrosion-resistant than brass, but it’s more difficult to machine. Brass has excellent machinability and is a preferred material for CNC turning.

II. Brass, Bronze & Copper. Will their chips or powder be harmful to CNC Machines?

Copper and its alloys (brass, bronze) do have some features that require special attention when machining. It does not mean that they”cannot be machined”, but that they must be “machined correctly”.

1) Potential Impacts of Machining Copper, Brass & Bronze on CNC Machines

| Table 8 – Potential Impacts of Machining Copper, Brass & Bronze on CNC Machines | |||

| Potential Risks | Causes | Controllable | Recommendations |

| Powder or fine particles are highly conductive | Copper and its alloy powder is conductive and may enter electrical control boxes, circuit boards, drive motors, and other areas | ✅ Controllable | Keep equipment sealed and strengthen powder removal and filtration to prevent it from entering critical electrical components |

| Fine chips easily accumulate and clog the chip removal system | Especially when machining copper and soft brass, fine chips or “sticky chips” are easily generated | ✅ Controllable | Use high-pressure coolant, automatic chip removal, and regularly clean the chip removal system |

| Lubricating oil can turn black and contaminate the machine’s interior | Copper may react chemically with certain cutting fluids, causing discoloration or precipitation. | ✅ Controllable | Choose a suitable copper alloy-specific cutting fluid and avoid inferior emulsions |

| Copper powder is slightly corrosive | Long-term unremoved copper shavings or powder react with coolant, potentially causing surface corrosion on some components | ✅ Controllable | Regularly maintain machine tool, focusing on cleaning areas like the turret and guide rails |

2) Recommendations from Practical Experience

● When machining large quantities of copper parts, it is recommended to physically isolate the CNC control box from the main machine body or install a sealant.

● Using an appropriate coolant and filtration system can effectively reduce problems caused by copper chips.

● Strengthen chip removal system management, such as configuring a spiral chip conveyor and a scraper chip conveyor.

● Regularly clean and maintain the machine interior (at least weekly).

● Factories with the necessary conditions can set up a dedicated “non-ferrous metal processing area” to manage their equipment independently.