1. Introduction

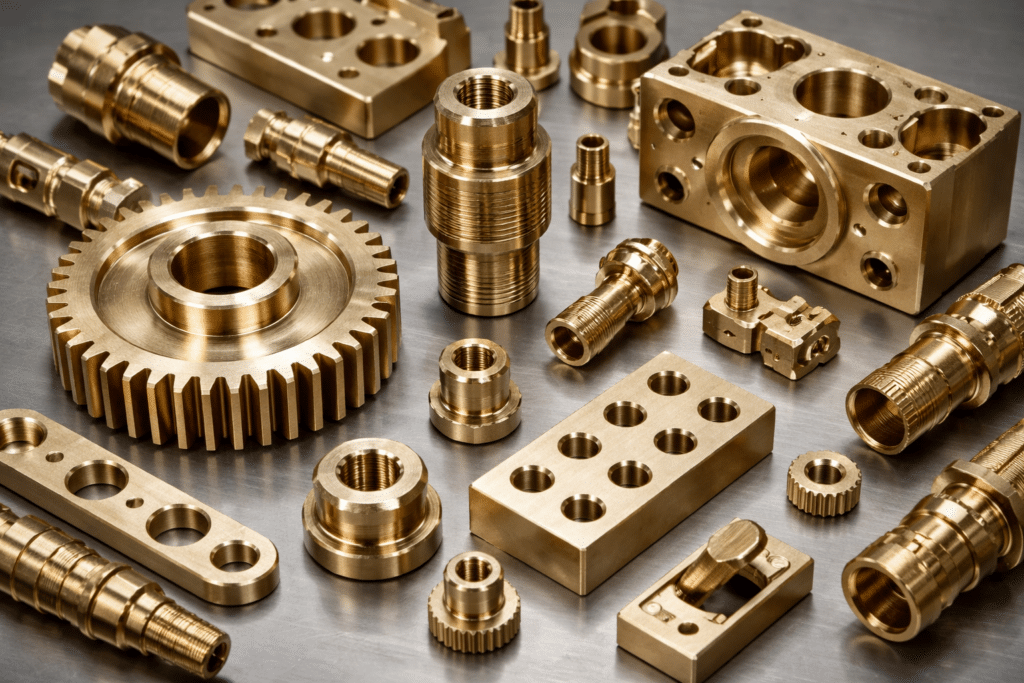

Brass remains one of the most popular alloys in precision engineering, serving as a cornerstone of Custom CNC Machining. Its unique combination of excellent machinability, high thermal and electrical conductivity, and a premium aesthetic finish makes it irreplaceable across diverse industrial sectors.

However, selecting brass for your project involves more than just its ease of cutting. Its specific physical properties—such as its non-magnetic nature and corrosion resistance—directly dictate its performance in real-world applications. This guide moves beyond basic manufacturing to explore how the unique material science of brass influences the design and durability of essential components, from industrial fittings to architectural hardware.

2. The Science of Brass: Key Physical Properties

Understanding the technical properties of brass is essential for determining its suitability for your custom parts. Unlike ferrous metals, brass offers distinct advantages in specialized environments.

2.1 Is Brass Magnetic?

Brass is a non-ferromagnetic material. Because it is primarily composed of copper and zinc, it does not interact with magnetic fields under normal conditions.

● Engineering Significance: This property makes CNC machined brass parts the gold standard for electronic enclosures, magnetic resonance imaging (MRI) components, and precision sensorswhere magnetic interference could compromise data accuracy or safety.

2.2 Does Brass Tarnish?

Yes, brass will naturally tarnish when exposed to oxygen and moisture. This process, known as patina, creates a thin oxidation layer on the surface that darkens the metal over time.

● Application Insight: While some architectural projects value the “antique” look of patina, most brass kitchen hardware and door handles require a pristine gold-like finish. To prevent tarnishing, we apply specialized surface treatments such as clear lacquering, PVD (Physical Vapor Deposition) coating, or chrome plating to lock in the original luster.

2.3 Does Brass Rust?

Strictly speaking, brass cannot rust. Rust is a chemical reaction (iron oxide) that only occurs in metals containing iron. However, brass can corrode if exposed to harsh chemicals or high salinity.

● Key Distinction: Unlike steel, which can flake away and fail due to rust, brass forms a protective carbonate layer when corroded, which actually slows down further metal loss. This makes it exceptionally durable for marine hardware and plumbing fittings that are constantly submerged or in high-humidity environments.

2.4 Material Comparison: Brass vs. Bronze vs. Copper

Choosing the right “red metal” depends on balancing performance with budget. Below is a technical comparison for CNC machining projects:

| Brass vs. Bronze vs. Copper | |||

| Feature | Brass | Bronze | Copper |

| Main components | Copper + Zinc (Zinc) | Copper + Tin (Tin) | Pure Copper |

| Magnetism | Non-magnetic | Non-magnetic | Non-magnetic |

| Machinability | Excellent (100%) | Fair (20-40%) | Difficult/Sticky (20%) |

| Corrosion Resistance | High | Superior | Great |

| Electrical Conductivity | Moderate (~28% IACS) | Low (~15% IACS) | Highest (101% IACS) |

| Cost | Economical | Expensive | Most Expensive |

| Typical Applications | Parts, hardware, connectors | Bearings, marine components | Electrical components, radiators |

Why is Brass the Preferred Choice?

While Copper offers better conductivity and Bronze offers slightly higher salt-water resistance, Brass is the most widely used for three main reasons:

● Cost-Efficiency: It is significantly cheaper than pure copper and most bronze alloys.

● Unbeatable Machinability: Brass can be machined at much higher speeds with minimal tool wear, drastically reducing the “cost per part.”

● Versatility: It strikes the perfect “Goldilocks” balance—durable enough for industrial valves, yet beautiful enough for luxury consumer goods.

3. From Properties to Products — Brass CNC Machining Applications

The superior physical properties of brass translate directly into high-performance components. By leveraging CNC precision, we transform raw brass alloys into essential parts across three primary sectors.

3.1 Industrial & Fluid Power: Reliability Under Pressure

In industrial systems, brass is the preferred material for components that must remain leak-proof and rust-free.

● Brass Fittings & Screws: Utilizing its natural corrosion resistance, brass fittings are essential for hydraulic and pneumatic systems. Unlike steel, brass provides a superior seal in threaded joints, ensuring that brass screws and fasteners maintain structural integrity even in high-humidity environments.

● Brass Fitters: These parts require extreme dimensional stability. Through CNC turning, we achieve tight tolerance control on internal and external threads, ensuring that fitters can withstand constant pressure cycles without fatigue or “seizing” (galling), a common issue with stainless steel.

3.2 Architectural & Furniture Hardware: Aesthetics Meet Hygiene

For interior design and furniture, brass is selected for both its “gold-like” luxury and its functional health benefits.

● Door Handles & Kitchen Hardware: Beyond its beauty, brass possesses natural antimicrobial properties. It can kill microorganisms within hours, making brass door handles and kitchen hardware a hygienic choice for high-touch surfaces in residential and commercial buildings.

● Custom Brass Hardware: Modern architectural trends often require complex, organic geometries. Multi-axis CNC machining allows us to create bespoke hardware with intricate details that would be impossible to achieve through traditional casting, all while maintaining a flawless surface finish ready for PVD coating.

3.3 Acoustic & Decorative Components: The Sound of Precision

Brass has unique acoustic resonances, making it the standard for high-end musical and signaling equipment.

● Brass Bells: The “ring” of a bell depends entirely on the material’s density and the uniformity of its walls. CNC machining ensures consistent wall thickness, which is critical for the acoustic pitch and clarity of brass bells. By removing the porosity issues found in sand casting, CNC machining produces a bell with superior resonance and a mirror-like decorative finish.

4. Technical Insights — Overcoming Challenges in Brass Machining

While brass is known for its excellent machinability, achieving a “premium” custom part requires mastering specific technical nuances. As a specialized CNC provider, we address several critical factors that generic manufacturing services often overlook.

4.1 Optimized Speeds and Feeds: C360 vs. Lead-Free Brass

Not all brass alloys are created equal. The strategy for cutting varies significantly depending on the lead content:

● C360 (Free-Cutting Brass): The industry benchmark. It contains approximately 3% lead, which acts as an internal lubricant. We utilize high cutting speeds (up to 300-500 m/min) and aggressive feed rates because the chips break easily into small, manageable pieces.

● Lead-Free Brass (e.g., C464 / Eco-Brass): Common in medical and potable water applications. Without lead, the material becomes “stringier” and generates more heat. We adjust by using sharper carbide tools and reducing feed rates by 15-20% to prevent work hardening and ensure a smooth finish.

4.2 Chip Management: Protecting High-Aesthetic Surfaces

One of the biggest challenges in machining brass—especially for brass hardware and handles—is “chip scratching.” Brass chips are often sharp and brittle.

● The Solution: We employ High-Pressure Coolant (HPC) systems to forcefully flush chips away from the tool path immediately. For decorative parts, we utilize “down-milling” strategies and specialized chip-breaker geometries to ensure that metallic debris never comes into contact with the freshly machined high-gloss surface.

4.3 Achieving the Perfect Finish: Post-Machining Options

Since brass is often chosen for its appearance, the “as-machined” surface is usually just the beginning. We offer four primary finishes for custom parts:

● Mirror Polishing: A multi-stage mechanical process to achieve a reflective, jewelry-like shine for luxury kitchen hardware.

● Brushing (Satin Finish): Using abrasive belts to create a consistent linear grain, popular for modern door handles to hide fingerprints.

● Passivation & Clear Coating: A chemical treatment that adds a microscopic protective layer to prevent the tarnishing (oxidation) discussed in Section 2.

● Electroplating (Chrome or Nickel): For brass fittings used in harsh environments, plating provides an extra layer of wear resistance and a silver-toned aesthetic while retaining the brass core’s corrosion benefits.

5. Conclusion — Choosing the Right Partner for Brass Machining

Selecting the right material involves more than just picking a metal; it’s about understanding how physical properties like magnetism, corrosion resistance, and machinability impact the lifecycle of your product. Whether you are developing non-magnetic housings for electronics, rust-free brass fittings for marine use, or high-aesthetic kitchen hardware, choosing the correct brass grade and CNC strategy is paramount.

By integrating material science with precision engineering, we ensure that every custom part meets your exact tolerances and functional requirements.

Ready to Start Your Brass Machining Project?

Don’t leave your precision parts to chance. Our team of engineers is ready to help you optimize your design for manufacturability (DFM) and select the perfect finish.

● Have a Design Ready? Upload your CAD files today to receive a professional quote and technical feedback within 24 hours.

● Need Expert Advice? Contact us to discuss how our CNC brass services can bring your project to life.

Expand Your Knowledge on Material Selection

If you are still evaluating materials for your next project, explore our in-depth technical guides:

● Comparing Red Metals? Check out our Bronze Machining: A Comprehensive Guide to see if bronze’s superior wear resistance is a better fit for your heavy-duty applications.

● High-Strength Requirements? Learn about the challenges and benefits of aerospace-grade metals in our Guide to Machining Titanium.

● Acoustic & Decorative Focus? Discover how we achieve perfect resonance and finishes in our guide on Precision CNC Machining for High-End Musical Instrument Components.