1. What Is Extrusion and Why It Still Dominates Modern Manufacturing

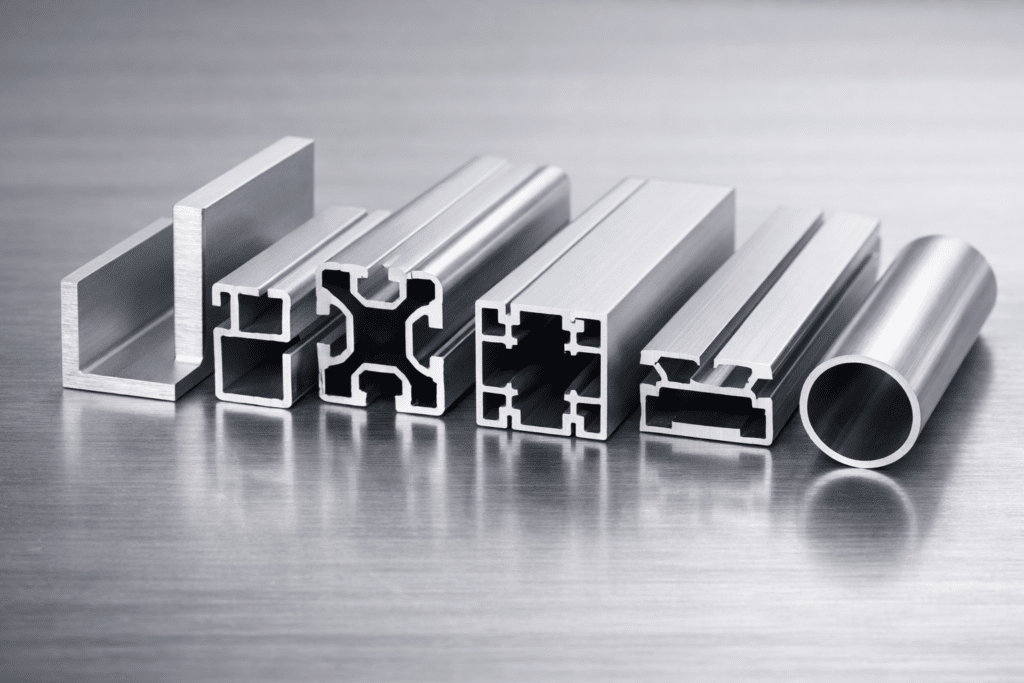

Extrusion remains essential in modern manufacturing because it delivers something most processes cannot: continuous, consistent production at scale. It is not chosen for complex shapes, but for its ability to produce long parts with uniform cross-sections, stable dimensions, and predictable quality.

What extrusion solves is consistency. Once the process is set, material flows through the die in a controlled way, allowing manufacturers to produce tubes, pipes, sheets, and profiles efficiently while maintaining repeatability over long production runs. This makes extrusion ideal for applications where length, fit, and downstream assembly matter more than part-by-part variation.

As manufacturing demands tighter tolerances, extrusion has also evolved into precision extrusion, where dimensional control, surface quality, and process stability are just as critical as output volume.

This article explores extrusion from a practical perspective, including tube extrusion, pipe extrusion, sheet extrusion, profile extrusion, and precision aluminum components, focusing on how the process supports real industrial applications rather than theory alone.

2. How the Extrusion Process Really Works

1) Material Flow, Pressure Control, and Die Design Logic

In real production, material flow during extrusion is never perfectly uniform. Temperature gradients, friction along the barrel, and resistance inside the die all create uneven flow paths. This is why two factories using the same die design can produce parts with very different dimensional stability and surface quality.

The key difference is process control, not equipment brand. Pressure balance across the die, melt temperature consistency, puller speed, and cooling rate all interact. Small deviations compound over long runs, leading to wall thickness drift, warpage, or surface defects.

This is where precision extrusion becomes a capability rather than a label. Precision extrusion depends on how well a manufacturer controls flow behavior over time—maintaining stable pressure, consistent material viscosity, and predictable die performance across thousands of meters of output.

2) Continuous vs Discrete Manufacturing: Why Extrusion Is Different

Extrusion is a continuous process, which fundamentally separates it from many other manufacturing methods.

- Extrusion vs Injection Molding

Injection molding produces discrete parts, one cycle at a time. It is ideal for complex 3D geometries but inefficient for long, uniform components. Extrusion, by contrast, produces continuous profiles where length and consistency matter more than part-level complexity.

- Extrusion vs Machining

Machining removes material to reach final shape. It offers flexibility but wastes material and scales poorly for long parts. Extrusion forms the shape directly, making it far more efficient for profiles, tubes, and sheets.

You should not use extrusion when parts require frequent dimensional changes, complex internal features, or low-volume customization. Extrusion excels when geometry is stable, volume is high, and consistency over length is critical—especially in precision extrusion applications where repeatability matters more than individual part variation.

3. Tube Extrusion vs Pipe Extrusion: Similar Process, Very Different Use Cases

Although tube extrusion and pipe extrusion use similar equipment and principles, they serve very different engineering and commercial purposes. Confusing the two is common—and costly—when specifications, tolerances, or compliance requirements are misunderstood.

1) Tube Extrusion: Precision, Tolerance, and Secondary Operations

Tube extrusion is typically used for applications where dimensional accuracy matters more than pressure rating. Extruded tubes are often structural or functional components that become part of a larger assembly rather than standalone conduits.

In tube extrusion, key requirements include:

- Roundness and concentricity, especially for mating parts or inserts

- Consistent wall thickness, critical for bending and machining

- Tighter tolerances, often driven by downstream processes

Tube extrusion is commonly followed by secondary operations such as cutting to length, bending, drilling, or CNC machining. Because of this, tube extrusion frequently overlaps with precision extrusion, where stability and repeatability over long runs directly affect final assembly quality.

Typical tube extrusion applications include frames, mechanical supports, housings, and precision components where geometry control is more important than compliance with pressure standards.

2) Pipe Extrusion: Standards, Pressure Rating, and Scale Production

Pipe extrusion is driven less by geometry and more by standards and certification. Pipes are designed to transport fluids or gases, which makes long-term performance, pressure resistance, and regulatory compliance the primary concerns.

In pipe extrusion, success is measured by:

- Conformance to industry standards

- Pressure rating and durability over time

- Material consistency across high-volume production

Because pipe extrusion often serves infrastructure, construction, or utility markets, it prioritizes scalability and long-term stability over tight dimensional tolerances. High output and proven reliability usually matter more than fine precision.

This is why pipe extrusion typically sacrifices tight tolerance control in favor of certified performance and cost efficiency at scale.

3) Tube vs Pipe Extrusion: A Practical Comparison Table

| Aspect | Tube Extrusion | Pipe Extrusion |

| Primary Use | Structural or functional components | Fluid or gas transport |

| Key Focus | Tolerance, roundness, concentricity | Standards, pressure rating |

| Typical Tolerance | Tight, often application-specific | Looser, standard-driven |

| Secondary Operations | Common (cutting, bending, machining) | Rare |

| Typical Industries | Industrial equipment, automotive, assemblies | Construction, utilities, infrastructure |

| Need for Precision Extrusion | Often required | Usually not |

Understanding the difference between tube extrusion and pipe extrusion is essential when selecting materials, suppliers, and processes. Choosing the wrong approach can lead to unnecessary cost, compliance issues, or performance failures—especially in precision extrusion applications where small deviations have large downstream effects.

4. Sheet Extrusion: Flat Profiles with Hidden Complexity

Sheet extrusion is often treated as a simple variation of extrusion, but in practice it is one of the most process-sensitive extrusion methods. Flat profiles amplify small process errors, making control far more critical than many assume.

1) What Sheet Extrusion Is

Sheet extrusion is not extrusion followed by flattening. It is a dedicated process where temperature control, melt uniformity, and roll calibration determine final quality.

In sheet extrusion, the material exits the die as a wide, flat profile and immediately enters a controlled roll stack. If temperature distribution is uneven or roll pressure is inconsistent, thickness variation, internal stress, or surface defects appear quickly.

Key control factors in sheet extrusion include:

- Precise thermal management across the full sheet width

- Balanced roller pressure and alignment

- Continuous monitoring of thickness consistency

Because flat geometry leaves little room to hide defects, sheet extrusion demands tighter process discipline than many round or closed profiles.

2) Typical Applications and Thickness Control Challenges

Sheet extrusion is widely used where large surface area and uniform thickness are essential.

Common applications include:

- Building and construction, such as panels and protective layers

- Industrial protection, including wear plates and barriers

- Packaging and industrial liners, where consistency affects performance and sealing

Across these applications, the main challenge is maintaining stable thickness over long production runs. Even small variations can lead to warping, poor fit, or premature failure in downstream use. This is why successful sheet extrusion relies less on output speed and more on continuous process control and quality monitoring.

5. Aluminum Extrusion in Industrial Applications

1) Why Aluminum Is Ideal for Precision Extrusion

Aluminum is one of the most widely used materials in precision extrusion because it balances performance, manufacturability, and cost better than most alternatives.

Its high strength-to-weight ratio allows extruded parts to remain structurally sound without adding unnecessary mass, which is critical in architectural, industrial, and transportation applications. Aluminum is also fully recyclable without loss of mechanical properties, making it suitable for long-term, sustainability-driven production strategies.

Just as important, aluminum extrusion is highly compatible with surface treatments such as anodizing, powder coating, and painting. This allows manufacturers to combine tight dimensional control with corrosion resistance and visual consistency—an advantage that many other extruded materials cannot offer.

2) Aluminum Extrusion L Bracket: A Simple Part That Reveals Everything

The aluminum extrusion l brackey is a deceptively simple component, yet it exposes nearly every critical variable in aluminum extrusion.

As a structural connector, an L bracket depends on:

- Accurate 90-degree angles, which reflect die balance and thermal control

- Consistent wall thickness, essential for load distribution and fastener alignment

- Clean surface quality, especially when anodizing or coating is required

In real production, aluminum extrusion L brackets rarely stop at extrusion alone. They often require secondary operations such as cutting, drilling, tapping, or CNC machining to meet assembly requirements. Any variation introduced during extrusion directly increases downstream cost and scrap.

Because of this, aluminum extrusion brackets are commonly used by engineers to evaluate a supplier’s true capability. When aluminum extrusion is stable, repeatable, and well-controlled, even simple parts like L brackets assemble cleanly, finish well, and perform reliably in demanding industrial environments.

6. Precision Extrusion: What “Precision” Actually Means in Practice

Precision extrusion is often marketed as a slogan. In reality, it is a measurable manufacturing capability defined by tolerance control, repeatability, and long-term process stability.

1) Dimensional Tolerance, Repeatability, and Process Stability

In extrusion, the difference between ±0.05 mm and ±0.2 mm is not cosmetic—it fundamentally changes how the process must be controlled.

Holding ±0.2 mm is achievable for many standard profiles with basic monitoring. Achieving ±0.05 mm, however, requires tight control of material temperature, extrusion pressure, pull speed, and cooling rate across the entire run. Any fluctuation accumulates over length, which is why precision extrusion is evaluated over meters, not individual samples.

Tooling also plays a decisive role. Die wear directly affects accuracy. As dies degrade, flow balance shifts, edges soften, and dimensions drift. Precision extrusion depends on disciplined die maintenance, predictable tool life, and controlled replacement cycles—not just initial die design.

When these factors are managed together, precision extrusion delivers consistent geometry, reliable downstream machining, and predictable assembly performance.

2) When Precision Extrusion Makes Sense

Precision extrusion is not always the right choice.

It makes sense when:

- Parts interface with other components

- Tight fit, alignment, or sealing is required

- Secondary machining cost depends on dimensional stability

It does not make sense when:

- Tolerances are loose or non-functional

- Volume is low and design changes are frequent

- Simpler processes can meet performance requirements

A capable supplier should help customers decide whether precision extrusion is necessary, rather than pushing it by default. Clear judgment builds trust—and ensures that precision is applied where it creates real value, not unnecessary cost.

7. Choosing the Right Profile Extrusion Company

Selecting a profile extrusion supplier is less about who has the biggest machines and more about who understands how profiles are actually used. For most projects, engineering capability outweighs equipment size.

1) Profile Design Capability Matters More Than Equipment

A strong profile extrusion company adds value long before production starts. The ability to optimize cross-section design can reduce material usage, improve strength, and simplify downstream processing without changing function.

Equally important is understanding downstream assembly. Profiles that look acceptable on paper may fail during cutting, drilling, fastening, or fitting if the extrusion design ignores real assembly conditions. Suppliers who understand how extruded profiles integrate into final products help prevent costly revisions later.

2) What to Look for in a Reliable Profile Extrusion Company

When evaluating a profile extrusion company, focus on capabilities that support long-term consistency rather than short-term output.

Key factors include:

- Engineering support to review designs and suggest practical improvements

- Tooling and die management, including maintenance and controlled replacement

- A structured quality system that monitors dimensional stability over long runs

- The ability to handle both low-volume pilot orders and high-volume production without sacrificing control

A reliable profile extrusion company does more than produce parts—it acts as a manufacturing partner that aligns extrusion performance with real application requirements.

8. Common Extrusion Problems and How Good Suppliers Solve Them

Extrusion failures rarely come from a single mistake. Most problems develop gradually as small process deviations accumulate over long production runs. The difference between average and reliable suppliers lies in how these issues are detected and controlled.

Uneven wall thickness is often caused by unbalanced material flow or uneven temperature distribution inside the die. Capable suppliers address this by tuning die geometry, stabilizing melt temperature, and continuously monitoring pressure across the profile rather than relying on initial setup alone.

Warping typically appears during cooling. If cooling rates are inconsistent, internal stress builds up and distorts the profile after exit. Good suppliers control cooling symmetry and adjust puller speed to maintain geometric stability over length.

Surface defects, such as lines, roughness, or discoloration, usually indicate contamination, die wear, or unstable flow. Reliable extrusion suppliers track die condition, control material quality, and intervene early—before cosmetic issues turn into functional failures.

Dimensional drift is one of the most costly extrusion problems because it often goes unnoticed until downstream assembly fails. Strong suppliers prevent drift through disciplined process monitoring, scheduled die maintenance, and tolerance tracking over time, not just at the start of a run.

What separates good extrusion suppliers from the rest is not the absence of problems, but the ability to control them before they impact performance, cost, or delivery.

9. Extrusion FAQs

1) What is the difference between tube extrusion and pipe extrusion?

Tube extrusion focuses on dimensional accuracy, roundness, and concentricity for structural or mechanical applications. Pipe extrusion prioritizes pressure rating, long-term stability, and compliance with industry standards for fluid or gas transport. Although the processes are similar, their design goals and tolerance expectations are very different.

2) Can aluminum extrusion achieve tight tolerances?

Yes, aluminum extrusion can achieve tight tolerances when the process is well controlled. Precision aluminum extrusion depends on stable temperature control, balanced die design, and consistent pull speed. Tighter tolerances require disciplined die maintenance and continuous monitoring throughout the production run.

3) Is sheet extrusion suitable for structural parts?

Sheet extrusion can be suitable for certain structural applications, but it depends on load requirements and thickness control. Flat profiles are sensitive to internal stress and warping, so structural use typically requires careful material selection and strict process control.

4) How do I choose a precision extrusion supplier?

Look beyond equipment size. A reliable precision extrusion supplier should offer engineering support, controlled tooling management, proven process stability, and experience with downstream operations. The right supplier helps determine when precision is necessary and when simpler solutions are more effective.

10. Conclusion: Extrusion Is Simple in Theory, Complex in Execution

Extrusion is often described as a straightforward process, but real manufacturing results depend on far more than pushing material through a die. Across tube extrusion, pipe extrusion, sheet extrusion, and aluminum extrusion, performance is defined by process control, tooling discipline, and long-term stability.

Precision matters when consistency, fit, and downstream operations are involved. Precision extrusion is not about marketing claims—it is about holding dimensions, managing die wear, and delivering repeatable results over full production runs.

If your project involves extruded tubes, pipes, sheets, or precision aluminum profiles, the next step is not choosing a process, but choosing the right approach and partner. An early engineering discussion can clarify tolerance needs, cost trade-offs, and manufacturability. When ready, a well-defined RFQ ensures extrusion performance aligns with real application requirements from the start.