1. Types of Titanium Alloys

Refer to the Article “Titanium vs Aluminum”, Section 1.3 Titanium Alloy Grades (see the article link below).

2. Machining Process for Titanium

Titanium alloys are widely used in aerospace, medical devices, automotive, and high-end equipment due to their high strength, low density, excellent corrosion resistance, and good biocompatibility. However, titanium alloys are also among the most difficult metal materials to machine. Below are some features of machining titanium.

2.1 Machining Features of Titanium Alloys

| Table 1 – Machining Features of Titanium Alloys | ||

| Features | Description | Impact on Machining |

| Low Thermal Conductivity | The thermal conductivity of titanium alloy is only about 1/6 of that of steel and about 1/20 of that of aluminum | Heat concentrates at the tool tip → Tool burnout and annealing discoloration of the workpiece surface |

| High Strength & Hardness | Maintains strength even at high temperatures (does not soften at 600°C) | High cutting forces, rapid tool wear, and low machining efficiency |

| Low Elastic Modulus | Only 1/2 that of steel | Workpiece prone to yielding and rebounding → Difficult to control dimensional accuracy |

| High Chemical Activity | Prone to reacting with tool materials (especially carbon) at high temperatures | Severe chip sticking and built-up edge, resulting in a sharp reduction in tool life |

| Intense Work Hardening | Once cut, the surface becomes harder | Difficult to cut again; depth of cut must be controlled |

| Easy to deform | High elasticity and thermal deformation | Thin-walled and long parts are prone to vibration and deformation |

2.2 Common Titanium Alloy Machining Processes

| Table 2 – Common Titanium Alloy Machining Processes | ||

| Process | Applications | Machining Key Points |

| Turning | For external machining of titanium rods and rings | Use sharp tools, slow speeds, high feeds, and adequate cooling |

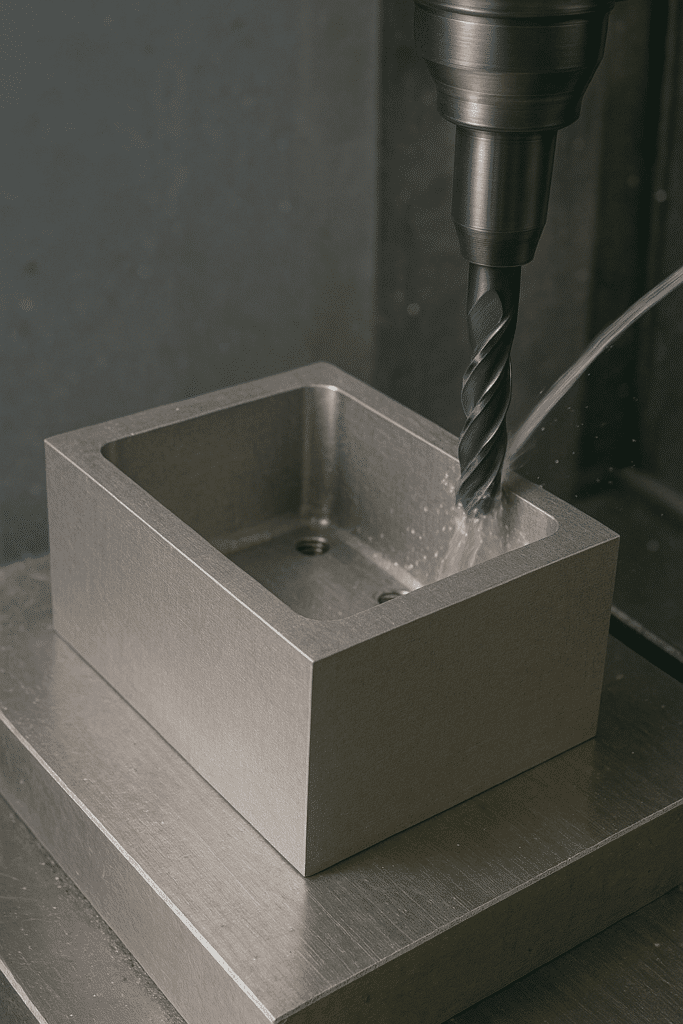

| Milling | For machining structural parts, cavities, blades, etc | Use high-rigidity end mills; control cutting depth and tool path |

| Drilling | For machining screw holes and through holes | Use specialized titanium alloy drills (such as TiAlN-coated carbide); control chip evacuation and cooling |

| Tapping | Internal thread machining | Prone to breakage; spiral-grooved taps with high-pressure coolant are recommended |

| Grinding | For precision surfaces or thin-walled parts | Use CBN or diamond grinding wheels to avoid burns |

| Electrical Discharge Machining (EDM) | For complex curved surfaces or hard-machined parts | No cutting force; post-treatment of the heat-affected layer is required |

| Laser Cutting / Drilling | For thin plates and small holes | The heat-affected zone must be controlled to avoid microcracks |

| Ultrasonic Vibration Machining | Precision hole and thin-walled workpiece machining | Significantly reduces cutting forces and chip sticking |

2.3 Tool and Material Selection

Tool Material: Coated carbide (TiAlN, AlTiN), CBN, Ceramic Tools

Tool Geometry: Large rake angle and sharp cutting edge; negative clearance angle reduces cutting heat

Tool Coating: TiAlN and AlCrN offer excellent high-temperature resistance and anti-sticking properties

Tool Lifetime Control: Tool lifetime is typically only 1/3–1/5 of that of steel parts, requiring timely tool replacement

3. Is It Hard to Machine Titanium? Tips for Titanium Machining

Titanium alloys are difficult to machine due to below reasons:

Poor Thermal Conductivity

During machining, a significant amount of cutting heat is generated at the point where the tool contacts the workpiece.

However, titanium alloys have a very low ability to transfer this heat, preventing it from quickly dissipating into the workpiece or the chips. Most of the heat is concentrated at the cutting edge of the tool, causing the tool tip to heat up dramatically.

This high temperature exacerbates tool wear, significantly shortens tool lifetime, and may even cause tool failure due to overheating during machining.

Strong Chemical Affinity

Especially at high temperatures, titanium alloys react chemically with many of the materials that make up the tool (such as the cobalt in carbides), causing “diffusion wear” or “crater wear” on the tool.

More importantly, during cutting, titanium chips easily weld to the tool surface, forming a “built-up edge” on the tool’s rake face.

This unstable built-up edge continuously grows and breaks off, not only damaging the finish of the machined surface but also removing tool material, further accelerating tool wear and breakage.

High Strength & Toughness

Titanium alloys are inherently strong and tough. This results in high cutting forces during machining.

At the same time, titanium alloys have a relatively low elastic modulus, which means the workpiece is more susceptible to elastic deformation and vibration under cutting forces.

This “cutting back” makes machining precision difficult to control and can cause chatter, compromising surface quality.

This is particularly challenging when machining thin-walled parts, as deformation is more pronounced.

Intense Work Hardening

Titanium alloys exhibit a pronounced tendency to work harden. Under the action of the tool, the machined surface undergoes plastic deformation, forming a hardened layer that is much harder than the substrate.

When the tool makes its next cut, its cutting edge must penetrate this hardened surface, akin to cutting through a material that is constantly hardening.

This creates severe impact and wear on the tool’s cutting edge, placing a significant strain on the tool’s toughness and wear resistance.

Chip Removal

Finally, chip removal with titanium alloys presents a challenge. Due to its high toughness, titanium alloys are less likely to break into short chips, instead forming thin, tough, ribbon-like chips.

If these entangled chips cannot be broken and discharged smoothly, they may be entangled in the tool or workpiece, scratching the processed surface, and may even cause safety accidents and interfere with the normal operation of automated production.

So how to overcome these challenges?

Machining Temperature Control

This is the key to addressing the issues of poor thermal conductivity and chemical affinity.

To achieve this, sufficient high-pressure cutting fluid must be used to ensure adequate cooling and lubrication. Ideally, the cutting fluid should be precisely directed at the point of contact between the tool and the chip to promptly remove heat and facilitate chip evacuation.

Where permitted, high-pressure cooling (above 70 bar) or spray cooling can even be employed to break the “air barrier” between the titanium alloy chip and the tool, ensuring that the coolant penetrates the cutting zone.

At the same time, avoid using pure oil-based cutting fluids, as they may exacerbate heat buildup.

Tool Selection

When selecting tools, special attention should be paid to material, geometry, and coating.

Micro- or ultra-micro-grain carbide tools are recommended, as they offer an excellent balance between hardness and toughness.

Regarding geometry, a large positive rake angle should be used to reduce cutting forces and heat, but the sharp cutting edge should be reinforced with appropriate chamfers to prevent chipping.

In addition, specialized physical vapor deposition coatings, such as titanium-aluminum-nitride or titanium-aluminum-nitride, can effectively reduce friction and the tendency to build up edge, while also acting as a thermal barrier to protect the tool substrate.

Machining Path

Optimizing machining path and parameters is crucial. Maintain a constant feed rate, and avoid pauses during cutting. Otherwise, repeated rubbing of the tool against the workpiece in the same position will cause transient high temperatures and work hardening, rapidly damaging the tool.

Feed should also be maintained during tool retraction to ensure that the machined surface is not scratched by the tool’s trailing edge.

Dynamic machining such as trochoidal milling or high-speed milling can shift from continuous cutting to intermittent cutting, allowing the tool to cool in the air and significantly reducing average cutting temperatures.

Cutting Parameters

Low linear speed is the most direct means of controlling cutting temperature. However, to avoid work hardening, the feed rate should not be too low.

A feed per tooth of at least 0.1 mm is generally recommended to ensure that the cutting edge cuts beneath the hardened layer.

Assuming sufficient rigidity for the machine tool, fixture, and cutter, a larger axial depth of cut combined with a smaller radial depth of cut can be used to increase the heat dissipation path from the cutting edge, while reducing the cutting width to reduce cutting forces.

Chip Control

Finally, process system rigidity and chip control are crucial for success.

The entire process system, including the machine tool, fixture, and workpiece itself, must possess extremely high rigidity to suppress the vibrations that are common during titanium alloy machining. For thin-walled parts, specialized fillers or fixtures may be necessary for added support.

For chip removal, except for the high-pressure cutting fluid flushing, tools with chip breakers or programmed tool paths to actively break chips can also be used to ensure smooth chip discharge and prevent secondary damage to the machined surface and tool.

4. How is Machining Titanium Different Than Other Materials?

4.1 Physical Properties

1) Titanium Alloy

● Medium density (approximately 4.5 g/cm³), approximately 40% lighter than steel, but with strength approaching or even exceeding that of high-strength steel

● Very low thermal conductivity, resulting in heat concentration at the tool tip during cutting, which can easily burn the tool

● Low elastic modulus, resulting in tool slippage and rebound during machining, making dimensional accuracy difficult to control

● Excellent corrosion resistance, highly stable in acidic, saltwater, and biological environments

● Therefore, titanium alloys are high-strength, lightweight, and corrosion-resistant materials, but suffer from poor machinability

2) Steel (including Carbon Steel, Stainless Steel, etc.)

● High density (approximately 7.8 g/cm³), excellent rigidity, and stable cutting performance.

● Better thermal conductivity than titanium alloy, allowing for easier heat dissipation and easier control of processing temperatures

● A wide range of materials and performance: Plain carbon steel is easy to machine, while stainless steel is more difficult

● A general-purpose structural material that balances performance and cost

3) Aluminum Alloy

● Low density (approximately 2.7 g/cm³), making it the lightest compared to titanium and steel

● High thermal conductivity, allows for rapid heat dissipation during machining and prevents tool burns

● Lower strength but good toughness, excellent machinability, and a smooth surface finish

● A lightweight, easy-to-machine, and aesthetically pleasing material

4.2 Machining Features & Costs

1) Titanium Alloy

● Concentrated cutting heat and rapid tool wear require the use of specially coated tools and high-pressure cooling

● Low cutting speeds require careful feed control, resulting in low processing efficiency

● Short tool life and long processing cycles → extremely high costs

● Intermediate stress relief annealing is often required after roughing to prevent deformation

● Processing costs are often 3to 6 times higher than those for steel

2) Steel

● Moderate machinability, suitable for most machining plants and tools

● Moderate cutting speeds and average cooling requirements

● Balanced tool life and processing efficiency

● Suitable for structural parts, mechanical components, and tooling

● Moderate overall cost, making it the most commonly used industrial processing material.

3) Aluminum Alloy

● Excellent machinability, capable of high-speed and light cutting

● Slow tool wear, smooth machined surfaces, and easy mirror finish

● High thermal conductivity prevents heat buildup during machining and reduces chip sticking

● However, its strength is low, making it prone to burrs and requiring careful deformation control

● Low processing cost and highest processing efficiency

4.3 Applications

1) Titanium Alloy

When products require weight reduction, strength, and stability in extreme environments, titanium alloy is the choice.

Typical applications include:

● Aerospace: Aircraft frames, engine blades, rocket casings. Here, even a gram of weight saving is crucial, and components must withstand immense stress and high temperatures

● Biomedical: Artificial joints, bone plates, and dental implants. Because it’s completely harmless to the human body and resistant to corrosive fluids, it’s the perfect metal for coexistence with the human body

● Top-tier athletics and chemical engineering: High-performance racing connecting rods, deep-sea exploration equipment, and highly corrosion-resistant chemical equipment

● High strength and stability in extreme environments, long lifespan, but at a high cost

2) Steel

When static structural strength, wear resistance, and cost control are top priorities in your design, steel is the most reliable choice.

Its applications are ubiquitous:

● Construction and Infrastructure: Rebar, bridges, and steel structures. These must withstand significant compressive and tensile forces

● Industrial Equipment and Molds: Machine tool bodies, gears, drive shafts, and injection molds. These require exceptional hardness, wear resistance, and stability

● Tools and Automotive Structures: Blades, chassis, and body frames. These require strict cost control while ensuring safety

● High material strength, low price, and mature processing technology make it the most economical and durable solution

3) Aluminum Alloy

When lightweighting, good heat dissipation, or rapid prototyping are key requirements, better choose aluminum.

● Consumer Electronics: Mobile phone cases, laptop bodies. They offer a balance of lightness, heat dissipation, and aesthetics

● Lightweight Structures and Transportation: Aircraft skins, high-speed rail interiors, car wheels, bicycle frames. They are widely used wherever weight reduction is necessary

● Heat Exchangers: Car radiators, air conditioner condensers. They take advantage of their excellent thermal conductivity

● Lightweight, easy to process, and with anodized surfaces, they offer both aesthetics and high efficiency

5. Surface Finishes for Titanium Machining Parts

After machining, titanium alloy parts typically require surface finishes to improve properties such as corrosion resistance, wear resistance, appearance, adhesion, or biocompatibility.

The surface finish of titanium alloys differs significantly from that of steel and aluminum. Because titanium is extremely chemically inert and self-passivating, conventional electroplating or oxidation methods often produce ineffective results. Specialized processes tailored to titanium are required.

5.1 Surface Properties and Treatment of Titanium Alloys

Common Problems After Machining Titanium Alloys:

● Darkening, oxidation, and the presence of stress layers

● High coefficient of friction, prone to interlocking with other metals

● Poor adhesion to coatings or paints

● Medical or aerospace parts require higher levels of wear resistance, corrosion resistance, aesthetics, or sterility

Therefore, common surface treatment is to:

● Enhance wear and corrosion resistance

● Improve surface lubricity

● Enhance decorative or reflective properties

● Improve adhesion of coatings or adhesives

● Improve biocompatibility for medical applications.

5.2 Common Surface Finishes for Titanium Alloys

5.2.1 Physical/Chemical Oxidation

1) Anodizing

● Titanium can undergo a unique titanium anodizing process

● A dense TiO₂ film is formed through an electrochemical reaction in an electrolyte (phosphoric acid, sulfuric acid, or an organic electrolyte)

● Different voltages can produce different colors (blue, purple, gold, green, etc.)- commonly used for exterior decoration

● Advantages: Corrosion resistance, heat resistance, and aesthetics

● Disadvantages: Average wear resistance, unsuitable for high-friction applications

2) Chemical Oxidation /Passivation

● Treatment in an acidic or alkaline solution to form a thin oxide film

● Used to improve adhesion, prevent discoloration, or provide minor corrosion protection

● Typically used as a pretreatment or light protection measure

3) Thermal Oxidation

● Heating in air or oxygen at high temperatures (500-800°C) forms a thick TiO₂ layer on the surface

● Enhances wear and corrosion resistance, but darkens the color (blue-gray)

● Commonly used for industrial parts rather than decorative items

5.5.2 Coatings and Platings

1) PVD (Physical Vapor Deposition) Coatings

● Includes TiN, TiCN, TiAlN, CrN, DLC (Diamond-Like Carbon), etc

● Significantly improves surface hardness (reaching HV2000 and above) and wear resistance

● Commonly used for: tools, bushings, valve cores, moving parts, etc

● Available in gold, black, gray, and other colors, it also offers decorative effects.

2) Spraying (Spraying + Heat Treatment)

● Includes ceramic spraying (Al₂O₃, TiO₂), PTFE spraying, and MoS₂ dry film lubricant coatings

● Used to reduce friction, prevent seizure, and prevent mold sticking

● Suitable for high-wear parts such as aviation, molds, and threads

5.2.3 Electroplating

● Titanium’s surface passivation layer is very stable, making it difficult for traditional electroplating to adhere directly

● If plating (such as nickel or gold) is required, the following must be performed first:

* Activation (treatment with hydrofluoric acid or ammonium fluoride solution)

* Then, an intermediate layer (nickel or copper plating) is applied as a transition layer

* The target coating is then applied

● Electroplating on titanium is generally used for conductive, anti-glare, or decorative applications, but the process is complex and costly

5.2.4 Sandblasting and Mechanical Treatments

1) Sandblasting/Shot Peening

● Removes machining stress layers and scale

● Creates a uniform surface roughness

● Provides good adhesion for subsequent anodizing and coating

● Medical titanium parts often undergo sandblasting and acid cleaning (SLA) to promote osseointegration

2) Polishing/Electropolishing

● Improves surface finish

● Electropolishing can also remove microscopic peaks and valleys, improving corrosion resistance

● Commonly used for medical and decorative parts

5.2.5 Surface Modification and Special Functional Treatment

1) Nitriding (Gas Nitriding / Plasma Nitriding)

● High-temperature diffusion in a nitrogen atmosphere forms a TiN layer

● Improves surface hardness and wear resistance

● Maintains dimensional stability and is commonly used on valve bodies, bearings, cutting tools, etc

2) Laser Surface Treatment

● Uses a laser to melt the surface, forming a strengthening layer or ceramic layer

● Precise control, suitable for high-end parts

3) Chemical Conversion Coating

● Such as phosphate coatings and chromate coatings (or chromium-free alternatives)

● Improves paint adhesion and is often used as a pre-coating treatment

4) Anodizing + Organic Coating

● Commonly used in medical and sports equipment, it combines decorative and corrosion-resistant properties

6. Common Applications for Machining Titanium

6.1 Aerospace Industry

This is the largest application area for titanium alloy machined parts.

Titanium alloys, with their high specific strength, high-temperature resistance, and corrosion resistance, are ideal structural materials.

● Aircraft engines: Known as the “heart” of an aircraft, these are where titanium alloys are used most heavily. Key components include compressor discs, blades, and casings.These components must operate in extreme environments of high temperature (often reaching 600°C), high pressure, and high speed. Titanium alloys not only withstand these conditions, but their lightweight properties also directly reduce engine weight and fuel consumption

● Aircraft fuselages and structural components: These include fuselage frames, bulkheads, landing gear components, fasteners, and helicopter rotor systems. Using titanium alloys in these areas can significantly reduce structural weight, increase payload or range, and ensure flight safety due to their high strength and fatigue resistance

6.2 Medical Devices

Titanium alloys are highly compatible with human tissue and are not rejected by the body. They are also corrosion-resistant and non-toxic.

● Artificial joints: such as hip, knee, and shoulder replacement prostheses. Titanium alloy’s elastic modulus is closer to that of human bone, reducing the “stress shielding” effect and promoting long-term bone health. Its excellent corrosion resistance ensures long-term stable operation in the human body’s fluid environment

● Bone Trauma Products: such as bone plates, screws, and intramedullary nails. They are used to stabilize fractures and promote bone healing. Processed titanium alloy implants can perfectly conform to the shape of the bone

● Dental Implants: These are tooth roots. Machined into a variety of fine threads and structures, they securely integrate with the jawbone (osseointegration), forming the foundation of high-end dental restorations.

● Skull repair plates and cardiovascular stents,etc.

6.3 High-End Chemical Engineering and Marine Engineering

Titanium alloys are resistant to corrosion from strong acids, strong alkalis, and saltwater, making them ideal materials for chemical equipment and marine structures.

● Chemical Equipment: Used in the manufacture of reactors, heat exchangers, pumps, valves, and piping systems, particularly in environments handling corrosive chemicals such as chlorine-alkali, nitric acid, and acetic acid

● Marine Engineering: Used in the housings and structural components of desalination plants, ship propulsion systems, and deep-sea exploration vehicles. Titanium alloys resist long-term corrosion from seawater, making them a key material for the development of marine resources

6.4 Competitive Sports and Luxury Consumption

In this sector, titanium alloy’s performance advantages are translated into an ultimate user experience and product value.

● Competitive bicycles: High-end frames, forks, and cranks. While maintaining extreme lightweight, they offer exceptional rigidity and strength, enhancing competitive performance

● Golf club heads: Especially wood club heads. Titanium alloy allows designers to create larger, thinner, and more forgiving club heads, while also providing improved feel and greater distance

● High-end watches: Cases and straps. Titanium watches are lightweight and comfortable to wear, and their understated gray metallic luster and wear resistance create a unique style statement

● Professional outdoor equipment: Such as top-quality trekking poles and backpack racks

6.5 High-Performance Cars and Racing Cars

The primary goal is extreme lightweighting to increase speed and fuel economy.

● Engine components: such as connecting rods, valves, and turbocharger blades. Reducing the weight of these high-speed moving parts reduces inertia, improving engine responsiveness and maximum speed

● Chassis and exhaust systems: Top-tier racing cars and supercars utilize titanium alloy bolts, brackets, and even entire exhaust systems. Titanium exhausts are not only extremely lightweight, but also withstand high exhaust temperatures and produce a distinctive sound

6.6 Electronics and Consumer Products

Titanium alloys are used in high-end product structural components due to their aesthetic qualities, wear resistance, and corrosion resistance.

Common machined parts include:

● High-end mobile phones, laptops, headphone casings, and smartwatch cases

● Camera parts, lens rings, buttons, and screws

7. People Also Ask

I. Any tips on machining Titanium grade 5?

Titanium Grade 5 Machining Considerations and Recommendations:

1) Material Properties

● Titanium alloys have high strength and low density (approximately 40% lighter than steel), but their low elastic modulus makes them prone to tool bounce and vibration

● They have extremely poor thermal conductivity (only about 1/6 that of steel), which concentrates cutting heat at the cutting edge, making them prone to tool burning or sticking

● Severe work hardening makes cutting more difficult once the tool is worn

2) Tool Selection

● High-quality carbide tools with coatings such as TiAlNor AlTiN are recommended

● Keep the tool edge sharp; dull tools easily heat up due to friction

● HSS (high-speed steel) tools are not recommended, as they have a shortened tool life

● Cutting Parameters

● Speed(RPM): Lower than when machining steel, generally maintained at 30–50 m/min

● Feed: Keep it high enough to prevent the tool from rubbing in the cutting zone (generating heat)

● Deep of Cut: Avoid cutting too shallowly, as shallow cuts can easily harden the surface

3) Cooling and Lubrication

● Forced cooling is crucial (high-pressure coolant is recommended)

4) Machine Rigidity and Fixtures

● Ensure the machine, tool holder, and workpiece fixtures are sufficiently rigid to reduce vibration

● Titanium is highly elastic and easily “pushes the tool,” so pay special attention to tool deflection during finishing

5) Surface Finish Recommendations

● Polishing, sandblasting, anodizing (coloring), or PVD coating are recommended after machining

● Polishing titanium alloys requires more effort than aluminum or steel. Fine sanding can be used first, followed by electrochemical or chemical polishing to achieve a smoother finish

Key Points

● Titanium has poor thermal conductivity and tends to accumulate heat at the cutting edge; heat transfer from the machining area to the workpiece is difficult → leading to faster tool wear, chip sticking, and tool burning

● Low elastic modulus and prone to vibration (tool bounce) → The tool/toolholder/workpiece must be as short and rigid as possible

● Use coated carbide tools (TiAlN/AlTiN coatings), not standard HSS

● Forced cooling and adequate chip evacuation

● Use a “steady tool, shallow cuts multiple times” technique or trochoidal/helical toolpath to control radial engagement

● It is recommended to perform a test cut (of scrap material) to find the optimal parameters for your machine tool, toolholder, and fixture

Tooling and Fixture Recommendations

● Roughing (High-Removal): Use a large-diameter end mill or face mill (indexable face mill or 3/4″–1″ 4-flute carbide). Use short-shank, rigid toolholders (hydraulic, shrink, or high-precision) to minimize overhang

● Semi-Finishing/Fine-Finishing: Use a short-shank, 2–4-flute carbide toolholder (variable-helix/high-helix can reduce vibration and improve chip evacuation)

● Deep Cavity/Long Overhang: If long overhang is necessary, reduce the depth of cut/radial engagement, use a dedicated long-shank toolholder, and minimize stock removal. Better yet, perform roughing operations in multiple steps to create steps before fine milling

● Drilling/Tapping: Use coated solid carbide or alloy high-speed steel (but carbide is preferred) drills, and segmented/peck drills. For tapping, use a spiral flute machine with extrusion/spiral flute tapping and lubricate thoroughly. If available, a thread mill is more reliable, especially for small-diameter, deep holes

● Cooling: High-pressure through-coolant (if available) is preferred

Path

● Use climb milling (almost always better)

● Cutting Method: Avoid large radial cuts (slotting). Prioritize reducing the radial cutting width (e.g., 10–30% of the diameter) and using multiple cuts. Trochoidal/dynamic milling can significantly reduce peak cutting forces

● For thin-walled or slender sections, remove the material in multiple passes and maintain clamping to avoid deflection

● For fine-finishing, use high feeds and shallow depths of cut whenever possible (the finish is determined by the final cut)

Drilling and Tapping (for 8-32)

● The most common drill size for 8-32 is #29 (≈0.136″) (standard UNC 8-32 recommended). You should tap a thread about 0.1–0.15″ deep at the bottom of the hole

● Drilling Strategy: Use a small-diameter pilot drill or intermediate drill to create a pilot hole, then drill the hole to the desired depth; use peck drilling (intermittent chip removal), low speed and high torque, through-coolant, and continuous flushing with cutting fluid

● Tapping:

* The safest method is thread milling or using the machine’s rigid tapping function and using the appropriate tap (a tap for a spiral groove machine, or a bottom tap for a bottom hole)

* When tapping by hand or by machine, use a low speed (lower than for aluminum or steel), adequate lubrication, and avoid forced back-and-forth after tapping to the bottom. When tapping a bottom hole (blind hole), use a bottom tap and cut in sections

* Tap extractors and spare taps are crucial – breaking taps in titanium can be difficult to repair

Tool Lifetime and Maintenance

● Tool lifetime is shorter than that of aluminum or steel. Observe tool wear (chipping, discoloration, increased chip extraction force) and replace promptly

● The toolholder should have good runout; runout accelerates wear and generates vibration

● Keep several frequently used tools on hand to mitigate tool breakage (especially for small-diameter tools)

Other Tips

● Vibration/Resonance: Check the fixture, shorten the reach, slow down, or change the speed to avoid resonant frequencies

● Thermal Deformation: Heat from titanium cutting is concentrated and difficult to dissipate. The tool should remove heat rather than retain it in the workpiece. Fine-Finishing is best done after removing a large amount of excess material, and the final cut path should be as short as possible

● Surface Color Difference/Heat Mark: If you see a blue/gray heat color, reduce the cutting temperature or speed/increase lubrication.

● Safety: Long and thin chips can easily entangle, so pay attention to machine cleaning and protection. Titanium powder and ultra-fine chips are flammable, so pay attention to chip recovery and fire prevention measures

Checklist (Before Starting)

● Ensure the toolholder and cutting tool are sufficiently rigid (short shank preferred)

● Ensure that the through-cooling system is functioning properly and providing stable cooling

● Check the rigidity of the fixture and whether shims/locators are used on the clamping surfaces to prevent deformation

● Prepare tools: 1/4″, 1/2″, and 3/4″ fine milling cutters + a 1″ or face milling cutter (depending on the amount of material removed)

● Prepare several #29 drills, suitable taps, or consider a thread milling cutter

● Perform a set of parameter verification on the test piece (one scrap part, same material and same clamping method)