1. What Is Aluminum Casting?

● Pour molten aluminum or aluminum alloy into a mold to create various shapes and sizes of parts

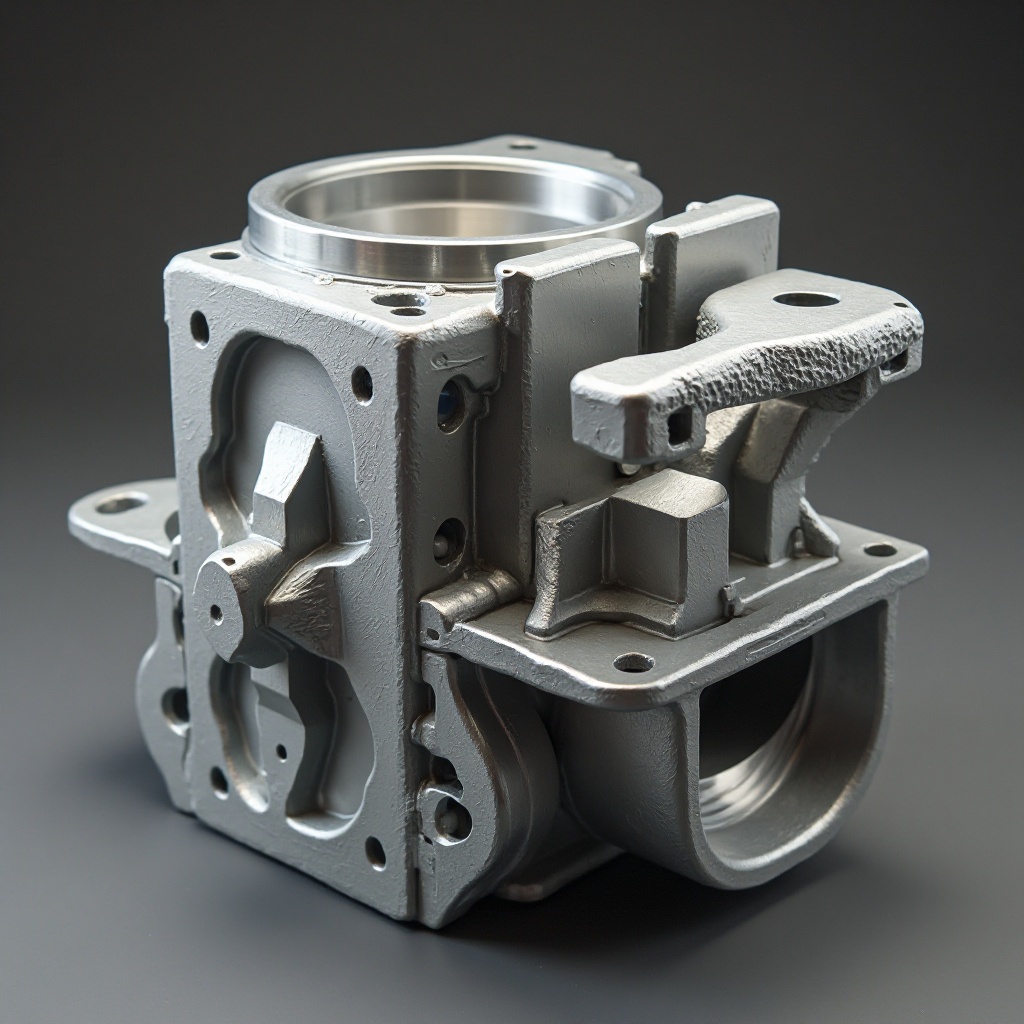

● Suitable for the manufacture of parts with complex shapes, hollow structures or that need to be lightweight

2. Advantages and Disadvantages of Aluminum Castings

2.1 Advantages

1) Lightweight

● Low density: Aluminum cast can significantly reduce the weight of parts and is suitable for fields with high requirements for lightweight (such as automobiles and aviation)

– Cast aluminum: about 2.7 g/cm³

– Cast iron: 7.2-7.8g/cm³

– Cast steel: about 7.8g/cm³

2) Good Mechanical Properties

● Medium strength:

– Through alloying (such as adding Si, Mg, Cu, etc.) and heat treatment (such as T6 aging), the tensile strength can reach 200~400 MPa

– 2A12 aluminum alloy: After proper heat treatment, its tensile strength can reach 390 to 420MPa

● High specific strength (strength/density ratio): Better than cast iron and regular carbon steel

● Excellent toughness: Compared with cast iron, aluminum castings have better impact resistance

3) Excellent Casting Performance

● Good fluidity: Aluminum alloys (especially high-silicon alloys such as A356) have good fluidity in the molten state and are ideal for complex thin-walled parts

● Low melting point: About 660°C (cast iron requires more than 1400°C), reducing energy consumption and mold loss

● Controllable shrinkage: Reduce shrinkage defects through process optimization (such as pressurized solidification)

4) Corrosion Resistance

● Natural passivation: A dense Al₂O₃ oxide film is easily formed on the surface, which is resistant to corrosion by the atmosphere, water and some chemical media

● Surface finish: Anodizing, electroplating or painting can further improve corrosion resistance

5) Thermal and Electrical Conductivity

● Thermal conductivity: about 150~220 W/(m·K), suitable for radiators, engine parts, etc.

● Electrical conductivity: about 60% of copper, can be used for electrical parts (such as motor housing)

6) Machining

● Easy cutting: After casting, it can be further processed by CNC, drilling, etc

● Weldability: Some aluminum alloys (such as 5xxx and 6xxx series) can be welded, but the weldability of cast aluminum alloys is generally poor

7) Shock Absorption and Wear Resistance

● Shock absorption: The damping characteristics are better than steel, a good choice for parts that are subjected to vibration

● Wear resistance: It can be improved by adding silicon (such as hypereutectic aluminum silicon alloy) or surface treatment (such as hard anodizing)

8) Environmental Protection and Recyclability

● 100% recyclable: The energy consumption of scrap aluminum remelting is only 5% of that of primary aluminum production, which meets the needs of sustainable development

2.2 Disadvantages

1) Mechanical Property Limitations

● Strength is lower than forgings or steel (tensile strength is usually 200-400 MPa), and needs to be improved by alloying/heat treatment

2) Low Hardness

● Surface strengthening (such as anodizing) is required to improve wear resistance

3) Risk of Internal Defects

● Porosity and shrinkage are prone to occur (especially in die castings), and process control is required

4) Poor High Temperature Performance

● For common cast aluminum alloys, the suitable working temperature is usually below 200°C (there may be alloys with higher operating temperatures, but such applications usually involve complex material processing and special manufacturing processes)

5) High Surface Treatment Requirements

● Porosity (die castings) needs to be sealed by infiltration, and high silicon alloy anodizing effect is poor

6) Poor Weldability

● Cast aluminum alloys (such as ADC12) are prone to cracking during welding and require special welding materials and processes

7) High Mold Cost

● Die casting/metal casting molds are expensive and only suitable for mass production

8) Cost Fluctuations

● Aluminum prices are greatly affected by the energy market

3. Different Aluminum Casting Processes and Their Applications

3.1 Sand Casting

Process Features:

● Process: Manufacture parts by injecting liquid metal materials

● Mold: Use sand mold (clay sand, resin sand, etc.) to make a disposable mold

● Advantages:

– Low mold cost

– Can manufacture large and complex structural parts (such as machine tool base, valve housing)

– No special requirements for alloy types (can cast iron, cast steel, etc.)

● Disadvantages:

– Rough surface, requires post-treatment

– Long production cycle, strong dependence on manual labor

– Prone to cause defects such as pores and sand holes

Typical Applications:

● Large/single-piece production: engine block, machine tool base, ship parts

● Complex structures: artwork, sculptures, pipe fittings

3.2 Investment Casting (Also Known As Lost-Wax Casting or Precision Casting)

Process Features:

● Process:

Create a wax pattern of the desired shape → coat it with refractory materials → melt out the wax → leave a mold without parting line → high temperature roast → pour molten metal → precise metal parts

● Mold: typically made of hardened tool steel, or harder alloy steel at higher temperatures

● Advantages:

– High dimensional accuracy and geometric accuracy

– Smooth surface

– Can cast with complex shapes

– No restriction on the casted materials

– Suitable for both single-piece customization and mass production

● Disadvantages:

– Complex processes and high costs

– Suitable for small and medium-sized parts (generally not more than 100 kg) due to limitations of shell material and process stability, not ideal for large-sized products

Typical Applications:

● Precision parts: aerospace turbine blades, medical devices

● Complex art pieces: jewelry, precision gears

3.3 Die Casting

Process Features:

● Process: inject molten metal into a metal mold at high speed under high pressure, then metal cools and solidifies under pressure to form a casting

● Mold: typically made of hardened tool steel, or harder alloy steel at higher temperatures

● Advantages:

– Good quality and stable sizes

– Smoother surface, higher dimensional consistency

– High production efficiency

– Mold lifetime is typically from tens of thousands to hundreds of thousands of shots

– Ideal for high volume production of small and medium-sized castings, with good economic benefits

● Disadvantages:

– High casting equipment and mold cost

– Prone to produce fine pores and shrinkage

– Die castings have low plasticity and are not suitable for working under impact loads and vibrations

– When die casting high melting point alloys, the mold lifetime is short, which affects the expansion of die casting production

Typical Applications:

● Automotive parts: engine parts, transmission systems, brake systems, suspension systems, etc

● Communication infrastructure: various housings and internal structural parts

● Household appliances: internal structure and shell of refrigerators, washing machines, air conditioners, etc

● Medical Equipment: various precision parts and housings

3.3.1 Aluminum Die Casting

● An indispensable material in automobile manufacturing due to its lightweight, high strength, excellent corrosion resistance and recyclability

● Widely used in the automobile manufacturing, aerospace, engineering machinery, construction and other fields

● Read the article link below to find more details on aluminum die casting

3.4 Low-Pressure Die Casting

Process Features:

● Process: inject molten metal into a metal mold under low pressure (0.02MPa to 0.06MPa) to create a casting

● Mold: can use sand mold, metal mold, graphite mold, etc

● Advantages:

– Can cast various alloys of different sizes

– The casting has high mechanical properties, smooth surface, and fewer pore defects

– Ideal to cast large, thin-walled parts

● Disadvantages:

– Long cycle time, high mold cost

– Not suitable for ultra-thin wall parts

Typical Applications:

● High-demand structural parts: automobile wheels, engine cylinder heads, aviation brackets

● Pressure-resistant parts: gas tanks, hydraulic parts

3.5 Centrifugal Casting

Process Features:

● Process: pour the molten metal into a rapidly rotating mold and solidify under the action of centrifugal force to fill the mold

● Mold: typically made from steel, cast iron, or graphite

● Advantages:

– There is almost no metal consumption in the pouring system and riser system, which improves the process yield

– When producing hollow castings, no core is required, so the metal filling capacity can be greatly improved when producing long tubular castings

– The casting has few defects (such as pores and slag inclusions), and high mechanical properties

– Easy to manufacture composite metal castings, such as tubes and sleeves

● Disadvantages:

– There are certain limitations when used to produce special-shaped castings

– The inner hole diameter of the casting is inaccurate, with rough hole surface, poor quality, and large machining allowance

– Castings are prone to specific gravity segregation

Typical Applications:

● Symmetrical rotating parts: aluminum tubes, bearing bushings, flywheels

3.6 Permanent Mold Casting

Process Features:

● Process: pour liquid metal into a metal mold to create metal components

● Mold: typically made of steel or cast iron to build reusable molds, which can be reused many times (hundreds to thousands of times)

● Advantages:

– High mechanical properties, for the same alloy (compared to the sand casting):

** Tensile strength: increased by about 25% on average

** Yield strength: increased by about 20% on average

** Corrosion resistance and hardness: significantly improved

– High precision and surface finish, stable quality and size

– High production efficiency

– Simple process, easy to mechanize and automate

● Disadvantages:

– High mold cost

– For ferrous alloy castings, it is limited to producing medium and small castings with simple shapes

– The metal mold has no air permeability, and certain measures must be taken to guide the air in the mold cavity and the gas generated by the sand core

– The metal mold has no yield, and cracks are easy to occur when the casting solidifies

– The manufacturing cycle of the metal mold is long and the cost is high, making it suitable for the mass production of non-ferrous alloy castings

Typical Applications:

● Automotive parts: pistons, wheel hubs, brake drums

● Industrial parts: pump housings, hydraulic valve bodies

3.7 Vacuum Die Casting

Process Features:

● Process: metal is melted, poured and crystallized in a vacuum chamber

● Mold: typically made from materials that have high strength, high thermal stability, excellent thermal fatigue and corrosion resistance

● Advantages:

– Eliminate or reduce the pore defects, improve the mechanical properties and surface quality

– The casting can be heat-treated to obtain better microstructure and mechanical properties

– Reduce the back pressure of the filling mold, which can cast smaller wall thickness of the casting

● Disadvantages:

– The mold sealing structure is complex, and it isn’t easy to manufacture and install, which causes high costs

– The casting effect is not good if an improper process occurs

Typical Applications:

● Aviation: aircraft engine impellers, turbines, turbine blades, spacecraft parts

● Automotive parts: engine parts, electronic device housings

3.8 Extrusion Casting

Process Features:

● Process: pour liquid or semi-solid metal under high pressure to directly create castings

● Mold: typically made from materials with high thermal resistance and durability

● Advantages:

– Eliminate internal defects such as pores, shrinkage, etc

– High dimensional accuracy

– Prevent the occurrence of casting cracks

● Disadvantages:

– Expensive equipment, suitable for high-performance requirements

Typical Applications:

● High-strength structural parts: automotive suspension parts, military equipment parts

3.9 Full-Mold Casting (Also Known As Lost Foam Casting or Evaporative Pattern Casting)

Process Features:

● Process: make a polystyrene foam pattern, pour the molten metal into the mold, causing the foam to vaporize and leave a cavity for the metal to fill

● Mold: made of foam plastic (such as EPS, STMMA or EPMMA)

● Advantages:

– High casting precision, no sand core, reduced processing time

– No parting line, flexible design

– Reduced investment and manufacturing costs

● Disadvantages:

– The mold can only be used once

– The mold is easy to deform due to low density and strength of foam plastic, affecting the dimensional accuracy

– The gas generated by the mold during casting pollutes the environment

Typical Applications:

● Various sizes of complex precision castings: gray cast iron engine cases, high manganese steel elbows, etc

3.10 Continuous Casting

Process Features:

● Process: pour the molten metal into a mold and continuously solidify it into a semi-finished product like a billet, bloom, or slab, then further processed in rolling mills

● Mold: commonly made out of graphite

● Advantages:

– Uniform structure and good mechanical properties

– Save metal and improve the yield

– Simplify the process, reduce the labor intensity and production area

– Easy to realize mechanization and automation, improves production efficiency

● Disadvantages:

– Can only produce long castings with unchanged cross-section

– Prone to produce fine pores and shrinkage

Typical Applications:

● Long length products: ingots, slabs, rods, tubes

4. How to Choose the Right Aluminum Casting Process?

| Table 1 – Process Recommendations | ||

| Process | Volume | Recommendations |

| Sand Casting | Single piece / low volume | Low-cost prototypes or large single-piece production |

| Investment Casting (Also Known As Lost-Wax Casting or Precision Casting) | Low volume | High-precision small parts (such as aviation and medical) |

| Die Casting | High volume | Large-volume thin-walled parts (such as mobile phone middle frames) |

| Low-Pressure Die Casting | Medium and high volume | High-quality structural parts (such as automotive key parts) |

| Centrifugal Casting | Medium volume | Rotationally symmetrical parts (such as aluminum tubes, cylindrical parts) |

| Permanent Mold Casting | Medium and high volume | Medium-volume parts with surface quality requirements |

| Vacuum Die Casting | Medium and low volume | High-demand parts (such as pressure-resistant, high-strength structures) |

| Extrusion Casting | Medium volume | High-load-bearing parts (alternative forging) |

| Full-Mold Casting (Also Known As Lost Foam Casting or Evaporative Pattern Casting) | Single piece / medium volume | Complex structural parts (such as engine manifolds) |

| Continuous Casting | High volume | Raw material preparation (such as rolling, extrusion billets) |

5. Surface Finishes for Casting Aluminum Parts

● Read the article link below (Section 4, Part 2: Surface Finish) to get more information

6. Conclusion

Casting aluminum is extensively used in automotive, aerospace, electronics, machinery manufacturing, and other fields due to its physical, chemical and mechanical properties.

The diverse aluminum casting processes can be applied to different applications. Select the right material and process based on product complexity, order quantity, precision and cost requirements to balance performance, efficiency and manufacturing cost. Combine multiple processes if needed (such as die casting + CNC machining).

Xiamen Eternal Precision’s 20+ years of expertise in die casting will help achieve your projects with cost-effectiveness and satisfaction. Contact our engineering team to start your journey.

7. People Also Ask

I. What to use for aluminum casting? I seen youtubers use soda cans. But they look ugly. And others do it and they look nice. Should I use soda cans Or Buy/get some aluminum tubing and melt that?

It depends on your needs, budget, and requirements for the quality of the finished product. Please see suggestions below:

1) Soda Cans

Advantages

● Free/Low Cost: Cans are easily available, suitable for practice and low-cost projects

● Fast Melting: Because the aluminum sheet is thin, it melts quickly

Disadvantages

● Many Impurities:

– Cans are aluminum alloys (usually containing magnesium, manganese, etc.), not pure aluminum, with poor fluidity and prone to defects during casting

– The inner wall has a plastic coating, which produces toxic fumes when burned (must be burned off or polished clean in advance)

● Severe Oxidation:

– The surface area is large, and a large amount of oxide slag (scum) is produced during melting, resulting in porous castings and low strength

● Poor Quality of Finished Products:

– The casting surface is rough and prone to pores, which is not suitable for parts that require strength or beauty

Applications

● Practice melting aluminum, making decorative parts or small non-load-bearing objects (such as key chains, ornaments)

2) Aluminum Tubes/Bars/Ingots (Recommended)

Advantages

● High purity:

– Industrial aluminum ingots (such as A356) or aluminum tubes/bars have fewer impurities, good fluidity, and denser castings

● High strength:

– Suitable for making functional parts (such as gears, brackets)

● Less oxidation:

– Less slag during melting and smoother surface of finished products

Disadvantages

● Higher cost:

– Aluminum ingots or aluminum tubes need to be purchased (but cheap sources may be found in the scrap aluminum market)

● Slower melting:

– Block aluminum requires higher temperature and longer time to melt

Applications

● Castings that require strength, precision or beauty (such as tool parts, model engine parts)

3) Other Aluminum Waste Options

● Door and window profiles: usually 6063 aluminum alloy, with good casting performance

● Auto parts: such as pistons and cylinder heads (note to remove iron parts)

● Wires: pure aluminum wire (skin needs to be peeled) has higher purity after melting

4) How to Make Castings More Beautiful (Regardless of The Type of Aluminum Material Used)

● Deslagging: thoroughly skim off the slag during melting

● Mold Quality:

– Use fine sand molds (such as resin sand) or metal molds

– Apply graphite powder or talcum powder to the mold surface to prevent sticking

● Pouring Tips:

– Pour slowly to avoid turbulence and bring in bubbles

– Preheat the mold (reduce pores)

● Post-Treatment:

– Polishing, sandblasting or anodizing improves surface texture

5) Suggestions

● Beginners: You can practice with cans first to get familiar with the melting and pouring process

● Advanced Level: Use aluminum tubes, aluminum ingots or high-purity scrap aluminum instead to improve the quality of the finished product

● Where to Buy:

– Aluminum ingots: Search for “aluminum ingots for casting” on e-commerce platforms (such as Amazon and Temu, etc)

– Scrap aluminum: scraps from local metal recycling stations or machining plant

II. Is aluminum good for casting?

Aluminum is a good choice for casting, especially for small to medium-sized parts with complex shapes and applications where lightweighting is required.

It is popular in both industrial casting and DIY sectors, but specific suitability depends on the alloy type, casting process and requirements.

1) Advantages of Aluminum Casting

● Low melting point

– The melting point of pure aluminum is about 660°C, which is much lower than that of iron (1538°C) or copper (1083°C), and is suitable for household smelting

● Good Fluidity

– Aluminum liquid has excellent fluidity (especially silicon aluminum alloy), can fill the details of complex molds, and is suitable for fine castings (such as gears, decorative parts)

● Lightweight

The density is only 2.7 g/cm³, which is 1/3 of steel, suitable for parts that need to be reduced in weight (such as drone parts, auto parts)

● Corrosion Resistance

– An oxide film is naturally formed on the surface, and its rust resistance is better than that of steel

● Easy to Machine

– After casting, it can be polished, drilled, anodized and other treatments to improve its appearance and functionality

2) Disadvantages of Aluminum Casting

● High shrinkage

– When aluminum solidifies, the shrinkage rate is about 6.5% – 6.6%, which makes it easy to produce shrinkage holes or deformation, and needs to be compensated by riser design or pressure casting

● Low strength

– Pure aluminum is soft, but its strength can be greatly improved by alloying (such as adding silicon, magnesium, and copper)

● Oxidation problem

– When aluminum is melted, aluminum oxide (Al₂O₃) slag is quickly formed on the surface, which needs to be skimmed regularly, otherwise it will affect the casting quality

3) Aluminum Alloy Suitable for Casting

● See Section 2, Part 2: Commonly Used Die Casting Aluminum Types and Their Applications for more information

4) Recommendations for Home Aluminum Casting

Material selection:

● Prefer cast aluminum alloy ingots (such as A356) rather than cans (with many impurities)

● Scrap aluminum can be used as door and window profiles (6063) or motor housings (usually containing silicon and good fluidity)

Process Optimization:

● Mold preheating (reduce pores)

● Slow cooling after pouring (reduce internal stress)

Safety Precautions:

● Aluminum liquid will explode when it comes into contact with water, so be sure to keep your tools dry!